A pipe string type cementing slurry rapid solidification device

A technology of cementing cement slurry and pipe string, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., and can solve problems such as erosion, pollution, and stratum engineering construction hazards, which have not been paid attention to and solved. Achieve the effect of improving the cementing quality and changing the liquid column structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

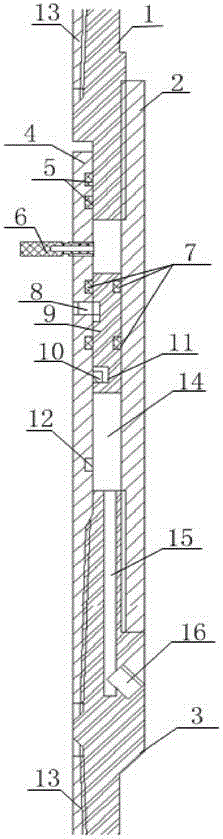

[0021] Such as figure 1 As shown, it is a schematic diagram of a string-type well cementing cement slurry rapid solidification device according to an embodiment of the present invention. It includes an upper joint 1, a lower joint 3, an outer pipe 2, and an inner pipe 4; the upper joint 1 and the lower joint 3 are respectively sealed and connected with the outer pipe 2 (the upper joint and the lower joint are respectively connected with the outer pipe by thread sealing , or through welding and sealing connection.); the inner tube 4 is fixedly installed inside the outer tube 4, and is located between the upper joint 1 and the lower joint 3, and the upper joint 1, the lower joint 3, the outer tube 2 and the inner tube 4 form an airtight space Cavity 14. exist figure 1 In the embodiment shown, the diameter of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com