A bottom-hole cementing slurry rapid solidification device

A technology of cementing cement slurry and outer pipe, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., which can solve problems such as erosion, pollution, loss of control, and entry, and achieve the effect of improving cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

[0026] Such as Figure 4 As shown, it is a schematic diagram of a rubber plug; the rubber plug 9 includes: a rubber plug iron core 94 , a rubber skirt 92 covers the upper end of the rubber plug iron core 94 , and a flange 96 is provided at the lower end of the rubber plug iron core.

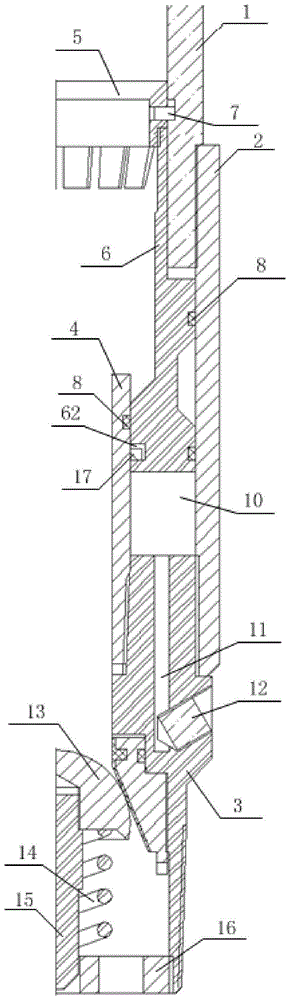

[0027] Such as figure 1 As shown, it is an overall schematic diagram of a bottom-hole cementing slurry rapid solidification device according to an embodiment of the present invention. It includes an upper joint 1, a lower joint 3, an outer pipe 2, and an inner pipe 4; the upper joint 1 and the lower joint 3 are respectively sealed and connected with the outer pipe 2 (the upper joint and the lower joint are respectively sealed with the outer pipe by threads) connected, or sealed by welding.); One end of the inner tube 4 is fixedly insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com