Mncr alloyed hot forming steel and production method thereof

A production method and hot forming technology are applied in the field of ultra-high-strength automotive steel materials, which can solve the problems of increasing the difficulty of steelmaking and difficult to control the boron content, so as to improve the precision of composition control, simplify the steelmaking process, and increase the yield of finished products. and productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

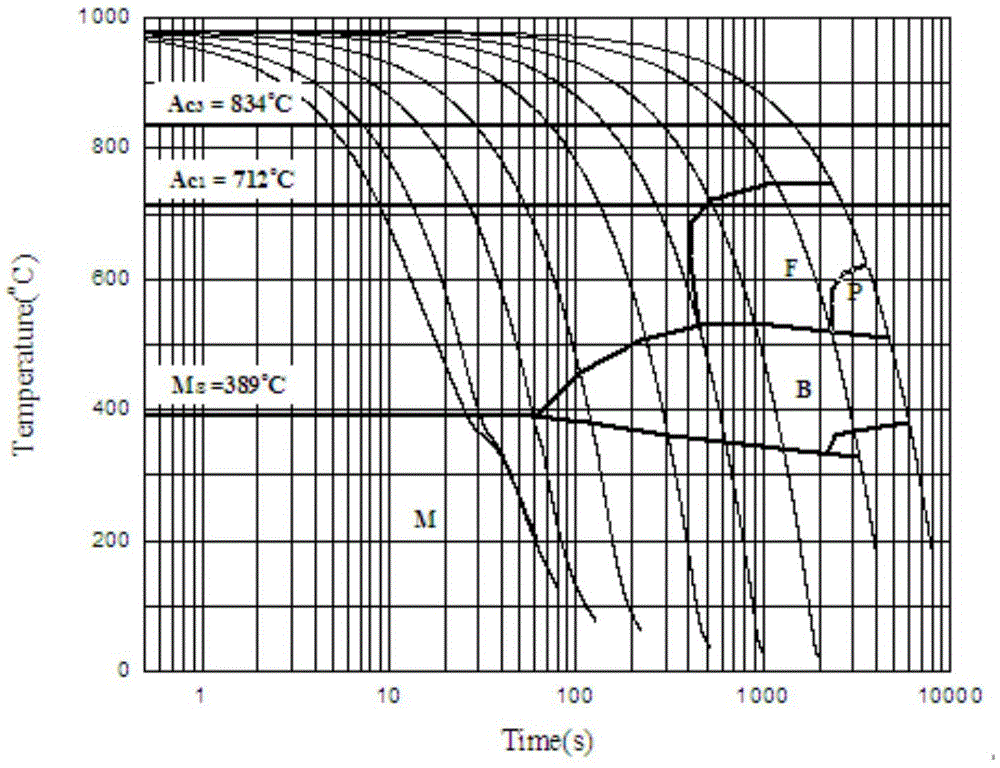

[0017] Measure the CCT curve of the steel slab obtained through continuous casting, measure the temperature-expansion rate curve at different cooling rates on the Gleeble3500 thermal simulation testing machine, and analyze the cooling curves at different cooling rates and the metallographic photos cooled to room temperature, and draw The CCT curve obtained is as figure 1 shown. The results show that Cr / Mn series steels for hot forming have good hardenability, and all martensitic structures can be obtained at a cooling rate of 20°C / s.

Embodiment 2

[0019] The steel slab obtained through continuous casting is heated to 1250°C, and after being kept for 60 minutes, it is put into a hot rolling mill for hot rolling. After 3 passes of rough rolling and 3 passes of finish rolling, a 4 mm hot-rolled steel plate for thermoforming is obtained. Heat the hot-rolled steel sheet for thermoforming to 930°C, keep it warm for 15 minutes, put it into a thermoforming testing machine for thermoforming to obtain a U-shaped part. The cooling rate of the steel plate during hot forming is about 20°C / s. The mechanical properties of the final thermoformed part are yield strength Rp=1030MPa, tensile strength Rm=1510MPa, uniform elongation Agt=5%.

[0020] After hot forming, the microstructure is all martensite, and the metallographic picture is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com