Method for producing ferro-titanium by remelting method

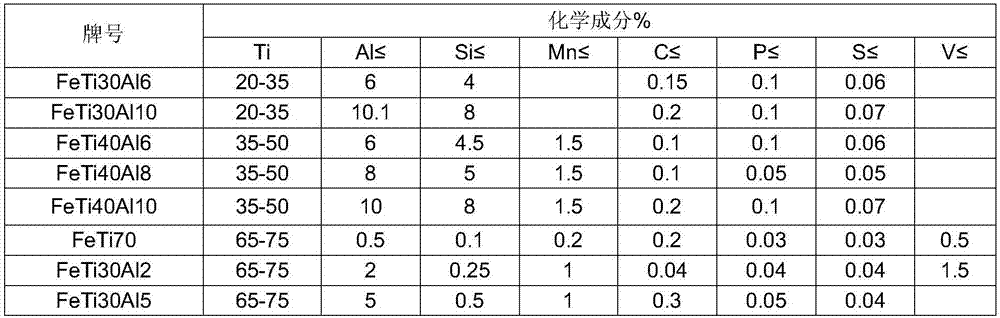

A technology of ferrotitanium and remelting, applied in the field of ferroalloy smelting, can solve the problems of large fluctuation of ferrotitanium, great hardness of ferrotitanium alloy, hard to break, short reaction time, etc., achieves low content of impurities and harmful elements, and simple and easy production method , The effect of high precision of composition control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Use converter and LF furnace to treat [C]+[Si]+[Mn]+[P]+[S]+[Al]+[V]+[Ti] of molten iron to 0.4%, and raise the temperature to 1710°C; Put the molten iron into the induction furnace, and continue to heat it under the condition of argon seal, add the extra sponge titanium (titanium content 99.8%) into the molten iron, and continuously blow the bottom blowing argon to stir and control impurities, the bottom blowing gas intensity is 0.3 N m 3 / t·min, the two metal liquids are mixed evenly, the ratio of titanium to iron is 3:7; after the homogenization is completed, the titanium-iron alloy liquid is plate-cast, and after the alloy is cooled to 100°C or below, the titanium-iron alloy is broken Package. The Ti content in the obtained ferro-titanium alloy is 29.89%, and the total content of other elements except iron is less than 0.3%.

Embodiment 2

[0037] Use an electric furnace to treat [C]+[Si]+[Mn]+[P]+[S]+[Al]+[V]+[Ti] in molten iron to 0.3%, and raise the temperature to 1700°C; Put it into the induction furnace, and continue heating under the condition of argon seal, add titanium shavings (titanium content 99.5%) into molten iron, and continuously blow argon to stir and control impurities, and the strength of the bottom blowing gas is 0.4Nm 3 / t·min, the two metal liquids are mixed evenly, the ratio of titanium to iron is 7:3; after the homogenization is completed, the titanium-iron alloy liquid is plate-cast, and the alloy is cooled to 100°C or below, and the titanium-iron alloy is broken Package. The Ti content in the obtained ferro-titanium alloy is 79.80%, and the total content of other elements except iron is less than 0.4%.

Embodiment 3

[0039] Use electric furnace + LF furnace to treat [C]+[Si]+[Mn]+[P]+[S]+[Al]+[V]+[Ti] of molten iron to 0.4%, and raise the temperature to 1720°C; Put the molten iron into the induction furnace, and continue heating under the condition of argon seal, add titanium chips (titanium content 99.8%) into the molten iron, and continuously blow argon gas at the bottom to stir and control impurities, and the intensity of the bottom blowing gas is 0.5Nm 3 / t·min, the two metal liquids are mixed evenly, the ratio of titanium to iron is 5:5; after the homogenization is completed, the titanium-iron alloy liquid is plate-cast, and after the alloy is cooled to 100°C or below, the titanium-iron alloy is broken Package. The Ti content in the obtained ferro-titanium alloy is 59.91%, and the total content of other elements except iron is less than 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com