Thermal energy storage spacing bar based on ethylene-vinyl acetate copolymer and preparation method of spacing bar

A technology of spacer and copolymer, which is applied to the field of heat storage and energy storage spacer based on ethylene-vinyl acetate copolymer and its preparation, can solve the problems of affecting the thermal insulation effect of insulating glass, no fundamental solution, and large thermal conductivity of aluminum. , to achieve the effect of improving energy saving and heat preservation effect, prolonging life and improving heat preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

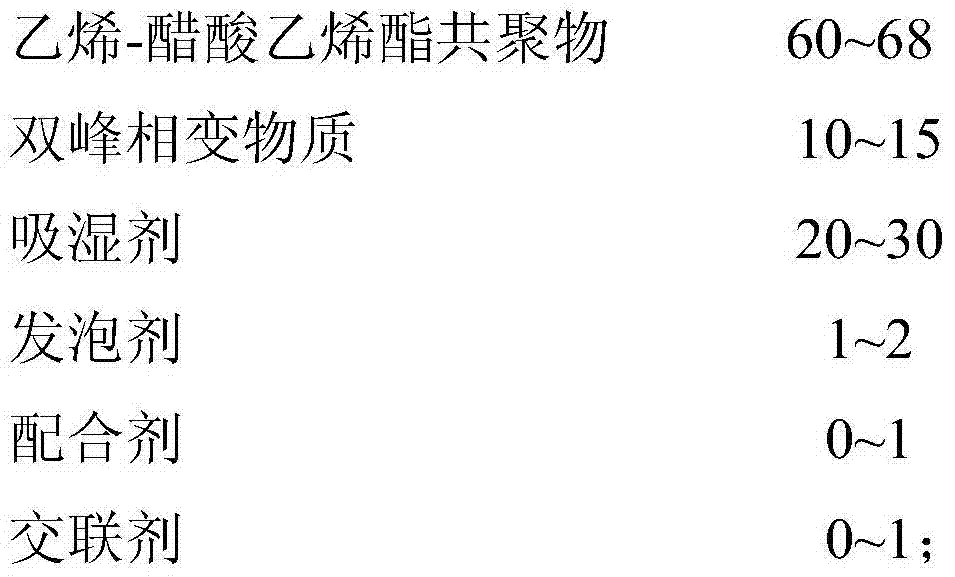

Method used

Image

Examples

Embodiment 1

[0033] Preparation of bimodal phase-change substances: Take 20 grams of phase-change paraffin (melting point: 28°C) and 80 grams of polyethylene wax, crush them with a pulverizer, put them into a three-necked bottle, put the three-necked bottle in an oil bath and heat up to 100°C, stir After 50 minutes, it was taken out, cooled, and pulverized to obtain a bimodal phase change substance.

Embodiment 2

[0035] Preparation of bimodal phase-change substances: Take 30 grams of phase-change paraffin (melting point: 28°C) and 70 grams of polyethylene wax, pulverize them with a pulverizer, put them into a three-necked bottle, put the three-necked bottle in an oil bath, heat up to 110°C, and stir After 45 minutes, it was taken out, cooled and pulverized to obtain a bimodal phase change substance.

Embodiment 3

[0037] Preparation of bimodal phase-change substances: take 25 grams of phase-change paraffin (melting point: 28°C) and 75 grams of polyethylene wax, pulverize them with a pulverizer, put them into a three-necked bottle, put the three-necked bottle in an oil bath, heat up to 120°C, and stir After 40 minutes, it was taken out, cooled, and pulverized to obtain a bimodal phase change substance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com