Squirrel-cage type self-rinsing micro-bubble generator

A micro-bubble generator and self-flushing technology, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of large particle size of micro-bubble, prone to short flow, dead flow, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

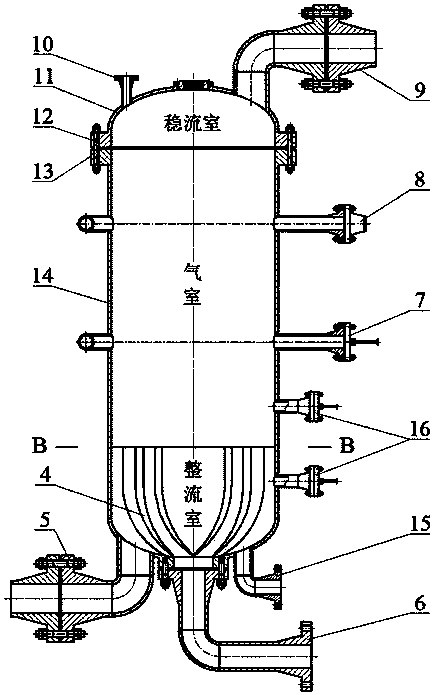

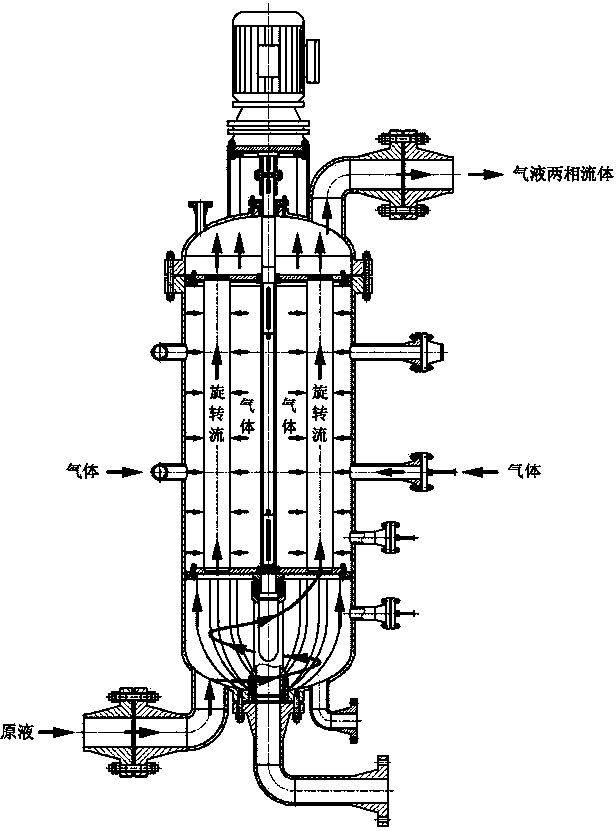

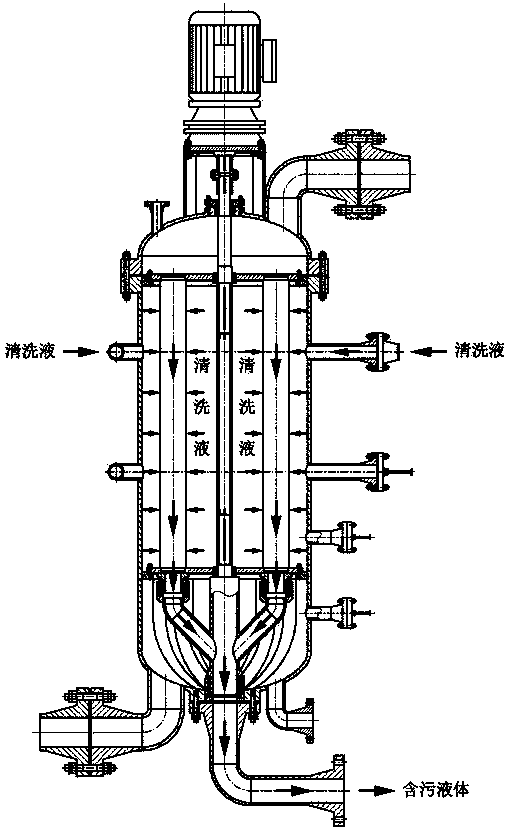

[0037] exist figure 1 and figure 2 Among them, the squirrel-cage self-flushing micro-bubble generator consists of self-flushing assembly 1, micro-bubble tank 2, squirrel-cage microporous membrane tube assembly 3, swirl blade 4, liquid inlet pipe 5, sewage pipe 6, air inlet pipe Sink 7, flushing manifold 8 and outlet pipe 9 are formed. When assembling, first connect the liquid inlet pipe 5, the sewage pipe 6 and their pipelines to the body of the microbubble tank 2 in sequence, and then put the flushing sleeve and the flushing pipe of the self-flushing assembly 1 into the rectifying chamber of the microbubble tank 2 And install the lower partition, then put the microporous membrane tube, transmission shaft and shaft sleeve into the air chamber of the microbubble tank 2 and install the upper partition, the uppermost end surface of the swirl vane 4 and the squirrel cage microporous membrane The positions of the microporous membrane tubes of the tube assembly 3 correspond one b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com