Green-quality resource solid-liquid separation equipment and feed producing method

A technology of solid-liquid separation and resources, applied in the direction of feed, animal feed, animal feed, etc., can solve the problems of poor effect, difficult operation, short drying time, etc., achieve good solid-liquid separation effect, simple equipment structure, and improve production quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

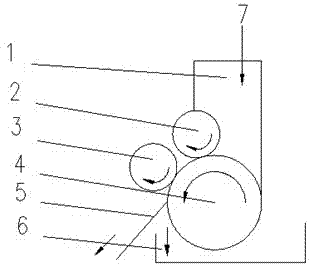

[0021] Please refer to figure 1 , the invention is a solid-liquid separation device for green resources. It comprises, the first pressing roller 4, and the first pressing roller 4 is provided with feed inlet 1; The second pressing roller 2 and the third pressing roller 3 installed in sequence along the rotation direction of the first pressing roller 4, and the described The second pressure roller 2 and the third pressure roller 3 are all meshed with the first pressure roller 4, and the gap between the second pressure roller 2 and the first pressure roller 4 is greater than that between the third pressure roller 3 and the first pressure roller 4. The gap is large, and the diameter of the first pressing roller 4 is larger than that of the second pressing roller 2 and the third pressing roller 3 . The first pressing roller 4 is connected with a driving device, and the driving device is a motor or a diesel engine. The first pressure roller 4 is an adjustable active rotation pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com