Kitchen garbage continuous classification device

A sorting device and kitchen waste technology, applied in the direction of garbage drying, filtration separation, separation methods, etc., can solve the problems of bacteria breeding, low efficiency of solid-liquid separation, health hazards, etc., achieve good results, eliminate the breeding of bacteria, and return materials convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

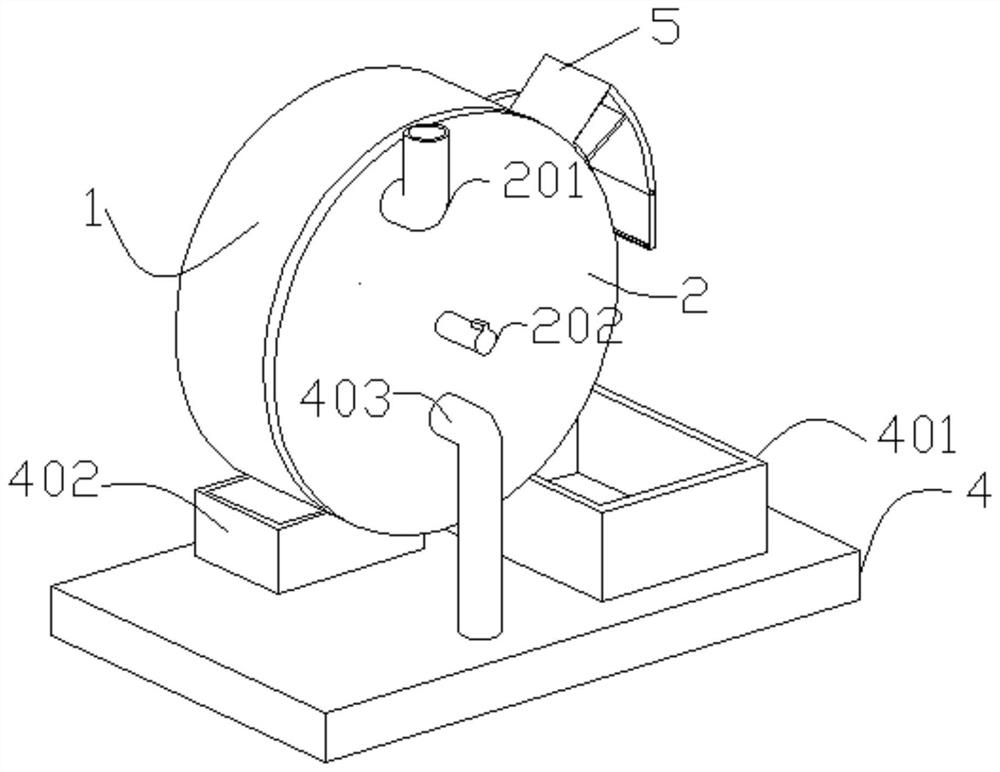

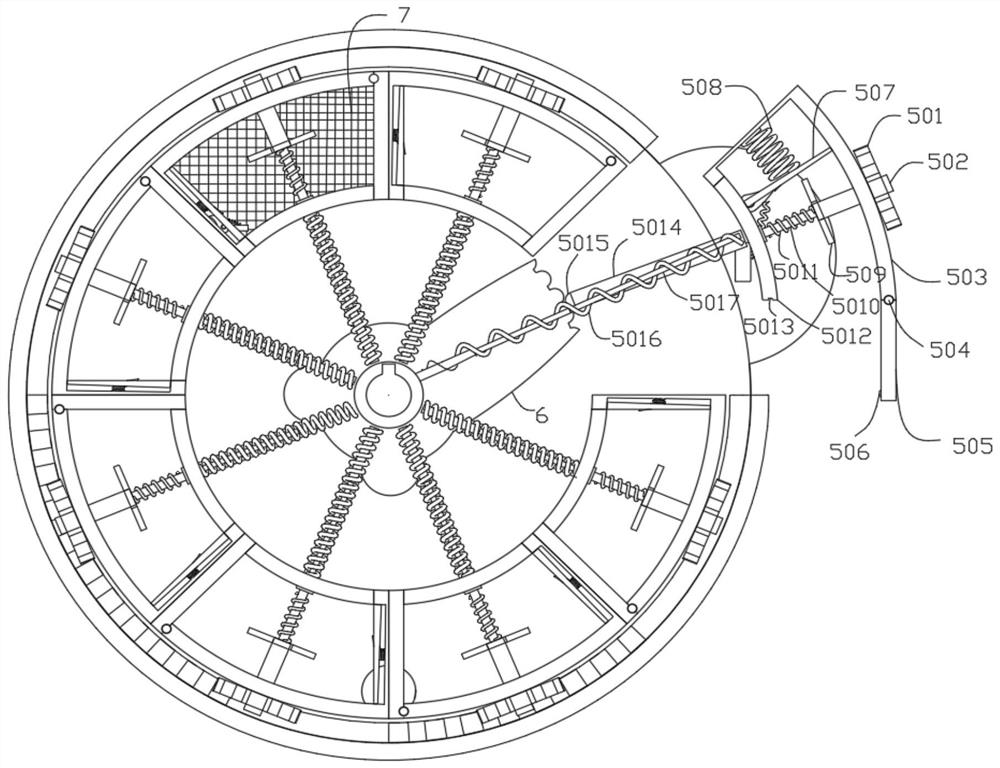

[0033] A continuous classification device for kitchen waste, including a housing, a base 4 and several separation devices 5 for solid-liquid separation, the separation devices 5 are rotatably arranged in the housing, and all the separation devices 5 are evenly distributed at equal angles Around the axis of the housing, a pusher compression device is arranged inside the separating device 5, and a plurality of ratchet devices 8 for cooperating with the pusher compression device are arranged inside the housing.

Embodiment 2

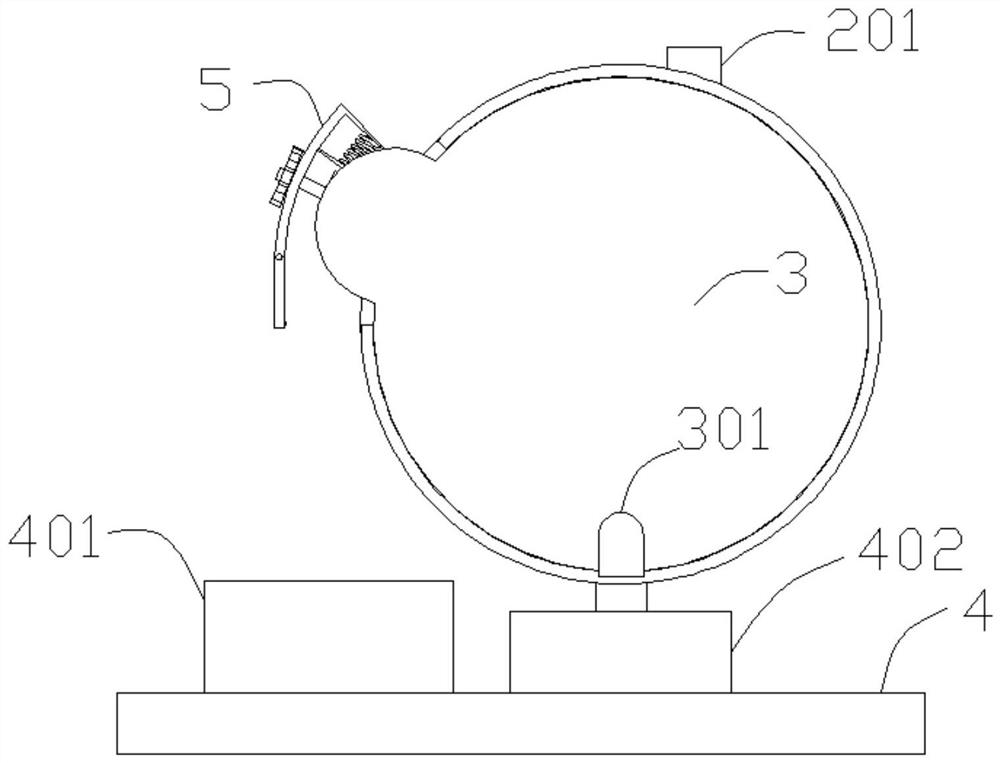

[0035] In a preferred embodiment of the present invention, on the basis of Embodiment 1, the housing includes a front shell 2, a sealing material shell 1 and a rear shell 3, and a rotating shaft 202 is provided through the middle of the front shell 2, so A feed pipe 201 is provided at the upper position of the front end surface of the front shell 2, and a support column 403 for supporting the shell is provided at the lower position of the front end surface of the front shell 2, and one end of the support column 403 is connected to the front shell. 2 is fixedly connected, the other end of the support column 403 is fixedly connected to the base 4, the sealing material shell 1 is arranged in the middle position between the front shell 2 and the rear shell 3, and the inner edge of the sealing material shell 1 There are several tooth pitches 9 arranged in a ring shape, and the tooth pitches 9 of several sections are composed of several tooth blocks. A separating cam 6 is fixedly arr...

Embodiment 3

[0037] In a preferred embodiment of the present invention, on the basis of Embodiment 1, the base 4 is provided with a water receiving bin 402 for receiving the waste water separated by the separation device, and the base 4 is provided with a water receiving bin 402 for receiving the waste water separated by the separation device. A receiving bin 401 for waste materials separated by the separation device 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com