System and method for realizing zero discharge of desulfurization wastewater in virtue of carrier gas extraction and bypass flue evaporation

A technology for bypassing flue and desulfurization wastewater, applied in chemical instruments and methods, extraction water/sewage treatment, gaseous effluent wastewater treatment, etc., can solve the problem of drug dosing pipeline blockage, insufficient treatment capacity, large floor area, etc. problem, to achieve the effect of small required space, low raw water requirements, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

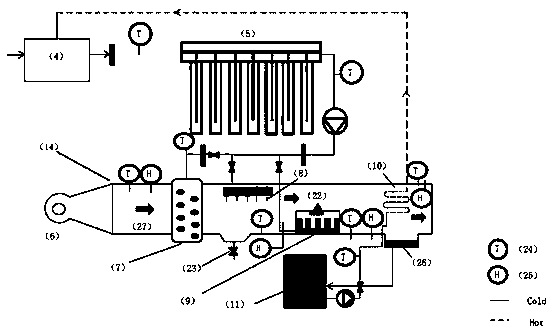

[0034] A zero-discharge system for desulfurization wastewater from carrier gas extraction and bypass flue evaporation, including a pretreatment integrated treatment system, a carrier gas extraction and concentration system, and an evaporation, crystallization and solidification system;

[0035] The pretreatment integrated treatment system includes integrated treatment equipment (1), screw dosing machine (2) and clean water tank (3);

[0036] The carrier gas extraction and concentration system includes a heat recovery system and a humidification-dehumidification system, the heat recovery system includes a low-temperature economizer (5) and a heat exchange tank (4), and the humidification-dehumidification system includes a dehumidifier (14) and cooling water tank (11);

[0037] The evaporative crystallization solidification system includes a bypass flue evaporator (12) and a dust collector (13);

[0038] The integrated treatment equipment (1) is respectively connected to the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com