Polishing pad for chemical mechanical polishing and preparation method thereof

A technology of chemical machinery and polishing pad, which is applied in the direction of grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of complex process, low reliability, long production cycle, etc., achieve simple process method and prolong service life , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

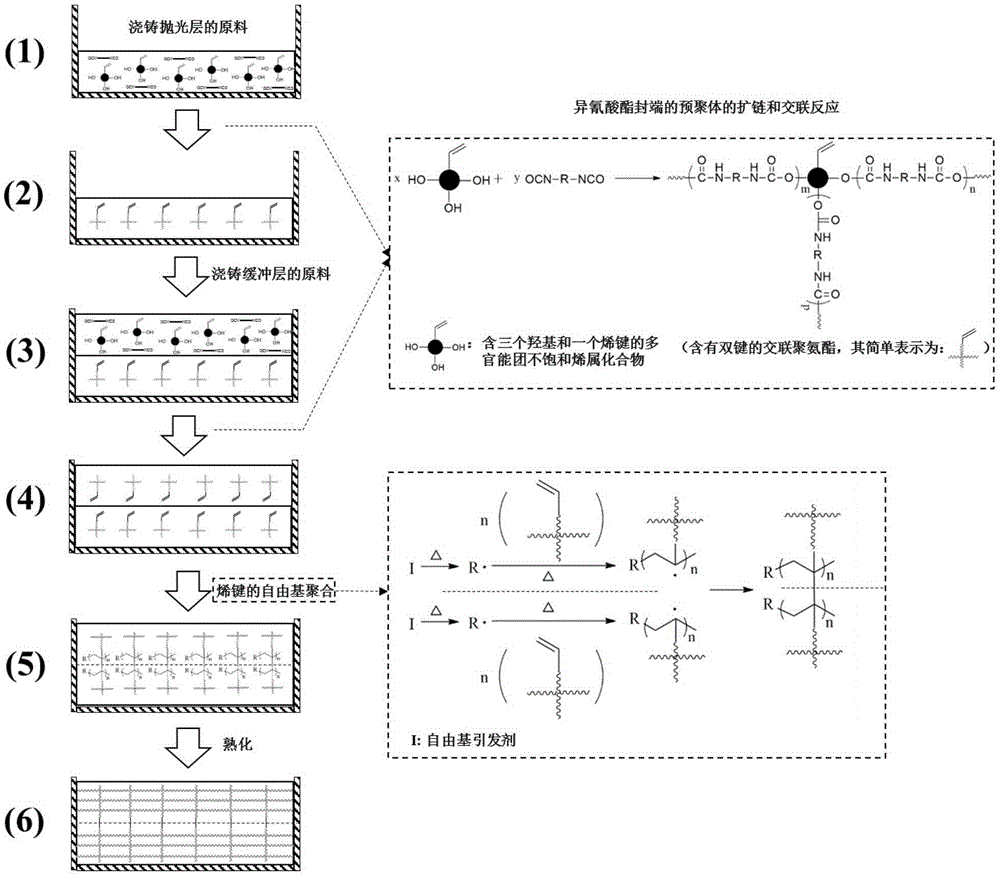

Method used

Image

Examples

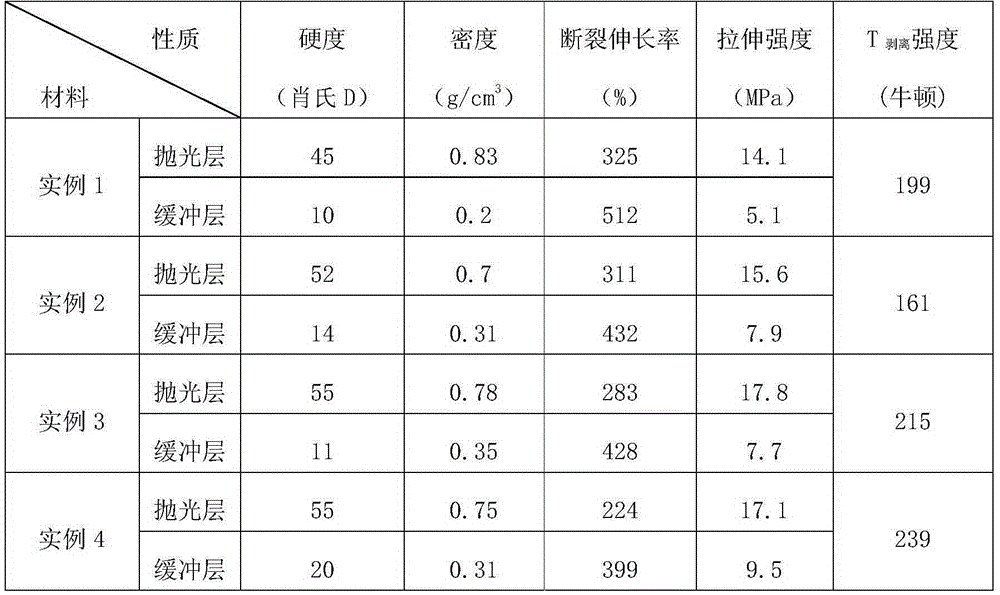

Embodiment 1

[0048] Raw materials for polishing layer:

[0049] Component A: 50.2% of 4,4'-diphenylmethane diisocyanate, 49.8% of polytetramethylene ether glycol with a molecular weight of 800, react at 70°C for 2 hours, vacuum (-0.095MPa) defoaming, A prepolymer with an isocyanate content of 28.0% was obtained.

[0050] Component B: 20.4% of 2,2′-diamino-3,3′-dichloro-4,4′-divinyldiphenylmethane, 78.2% of polypropylene ether diol with a molecular weight of 1000, and 0.1% of organic zinc catalyst , 1.0% of polymer microspheres, 0.1% of hard foam silicone oil and 0.2% of 2,2'-azobisisobutyronitrile, after rapid mixing, a uniformly dispersed mixed solution was obtained.

[0051] Mix components A and B at a mass ratio of 2:1 for 15 seconds at a stirring speed of 5000rpm, cast into a mold that has already been prepared, and gel at a temperature of 20°C for 10 minutes to obtain Uncured finish.

[0052] Raw materials for the buffer layer:

[0053] Component C: 48.9% of 4,4′-diphenylmethane...

Embodiment 2

[0057] Raw materials for polishing layer:

[0058] Component A: 40.2% liquefied 4,4′-diphenylmethane diisocyanate, 59.8% polytetramethylene ether glycol with a molecular weight of 800, react at 70°C for 2 hours, and vacuum (-0.095MPa) defoaming , to obtain a prepolymer with an isocyanate content of 23.2%.

[0059] Component B: 19% of 2,2′-diamino-3,3′-dichloro-4,4′-divinyldiphenylmethane, 79.6% of polypropylene ether diol with a molecular weight of 1000, and 0.1% of organic zinc catalyst , 0.8% of polymer microspheres, 0.3% of hard foam silicone oil and 0.2% of 2,2'-azobisisobutyronitrile, after rapid mixing, a uniformly dispersed mixed solution was obtained.

[0060] Mix components A and B at a mass ratio of 2:1 for 25 seconds at a stirring speed of 5000rpm, cast into a mold that has been prepared, and gel at a temperature of 20°C for 15 minutes to obtain Uncured finish.

[0061] Raw materials for the buffer layer:

[0062] Component C: 40.5% of 4,4'-diphenylmethane dii...

Embodiment 3

[0066] Raw materials for polishing layer:

[0067] Component A: 34.9% of 4,4'-diphenylmethane diisocyanate, 65.1% of polytetramethylene ether glycol with a molecular weight of 800, react at 70°C for 2 hours, vacuum (-0.095MPa) defoaming, A prepolymer with an isocyanate content of 20.6% was obtained.

[0068] Component B: 2-chloro-5-(4-methyl-3,5-divinyltoluene)-1,3-diphenylamine 23.1%, polypropylene ether glycol with a molecular weight of 1000 75.7%, organic bismuth catalyst 0.1 %, 0.8% of polymer microspheres, 0.1% of hard foam silicone oil and 0.2% of benzoyl peroxide, after rapid mixing, a uniformly dispersed mixed solution is obtained.

[0069] Mix components A and B according to the mass ratio of 2:1 at a stirring speed of 5000rpm for 25 seconds, cast into the prepared mold, and gel at a temperature of 25°C for 4 minutes to obtain Uncured finish.

[0070] Raw materials for the buffer layer:

[0071] Component C: 45% liquefied 4,4'-diphenylmethane diisocyanate, 55% p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com