Cone spiral grinding device

A grinding device and spiral technology, applied in grinding devices, grinding machine tools, grinding tools, etc., can solve the problems of separation of polishing and grinding, low degree of automation, low processing efficiency, etc., to improve processing efficiency and quality, simple structure Compact, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

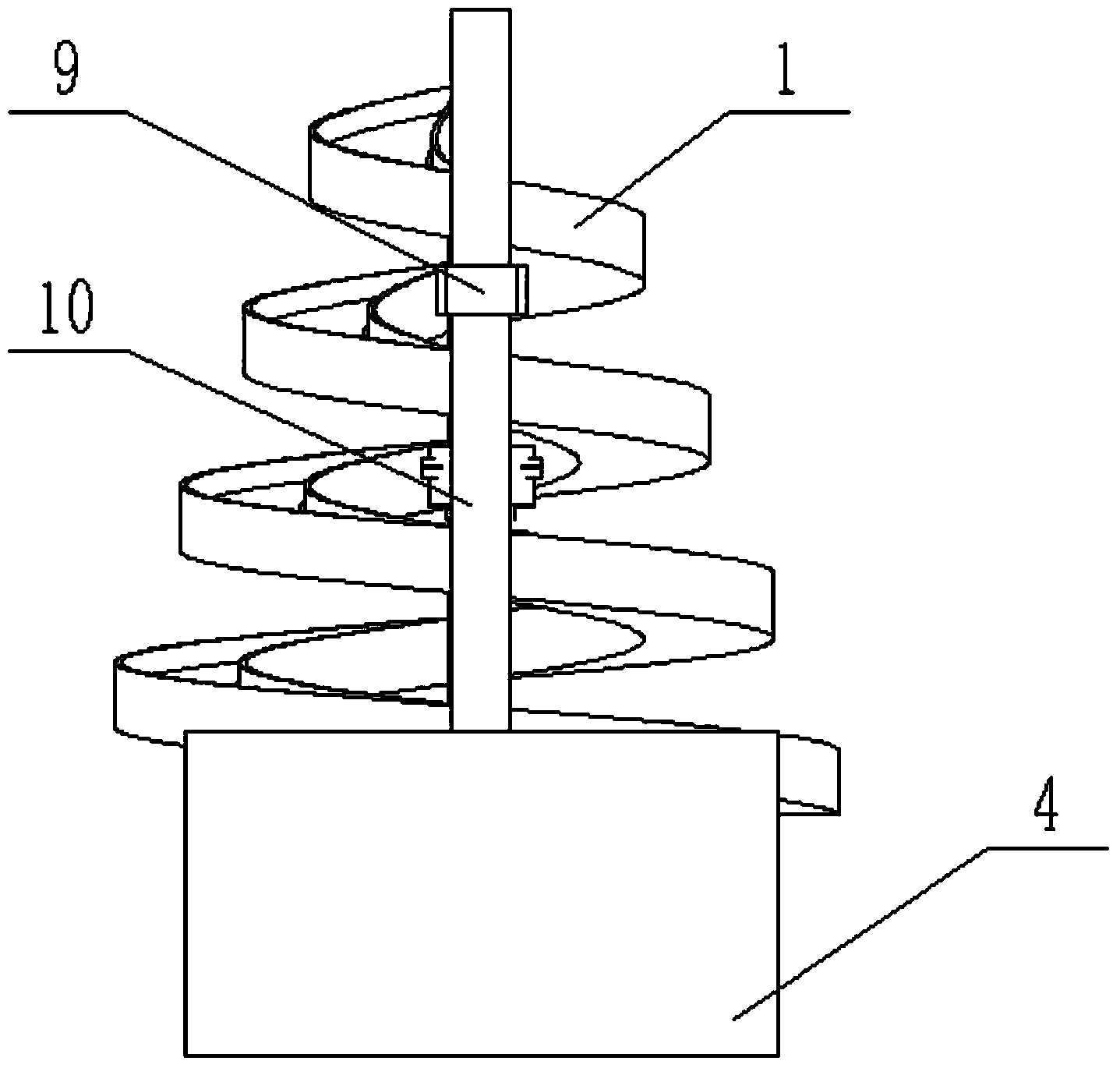

[0021] combine figure 1 , figure 2 , image 3 and Figure 4 , a conical spiral grinding device, comprising a frame base 4, a grinding disc 1, a workpiece feed mechanism and a workpiece mounting head 6, the workpiece mounting head 6 is bonded to the grinding disc 1, and the grinding disc 1 disc body is conical and spiral, The abrasive particle size on the surface of the grinding disc changes in a gradient manner with the helix of the disc body, the closer to the top of the cone helix, the higher the abrasive particle size; the workpiece on the workpiece mounting head 6 stays at different positions for different times, and the abrasive particle size is also different , the machining accuracy will be different. Because the workpiece is processed from the bottom of the conical spiral grinding disc, the abrasive grain size at the bottom of the conical spiral is the lowest, so the rough grinding can be started at the beginning, and the higher the precision of the processing is, ...

Embodiment 2

[0028] This embodiment is basically consistent with the solution of Embodiment 1, the only difference is that the workpiece mounting head 6 bottom surface is provided with a workpiece mounting hole, the workpiece is installed in the workpiece mounting hole, and there are multiple workpiece mounting holes, which are evenly distributed on the workpiece mounting head. on the underside. This mode can process multiple workpieces at the same time, which further improves the processing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com