Hydrogenation catalysts prepared from polyoxometalate precursors and process for using same to produce ethanol while minimizing diethyl ether formation

A hydrogenation catalyst, catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problem that the catalyst does not have ethanol selectivity and the catalyst does not have sufficient conversion. rate, excessive operating temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

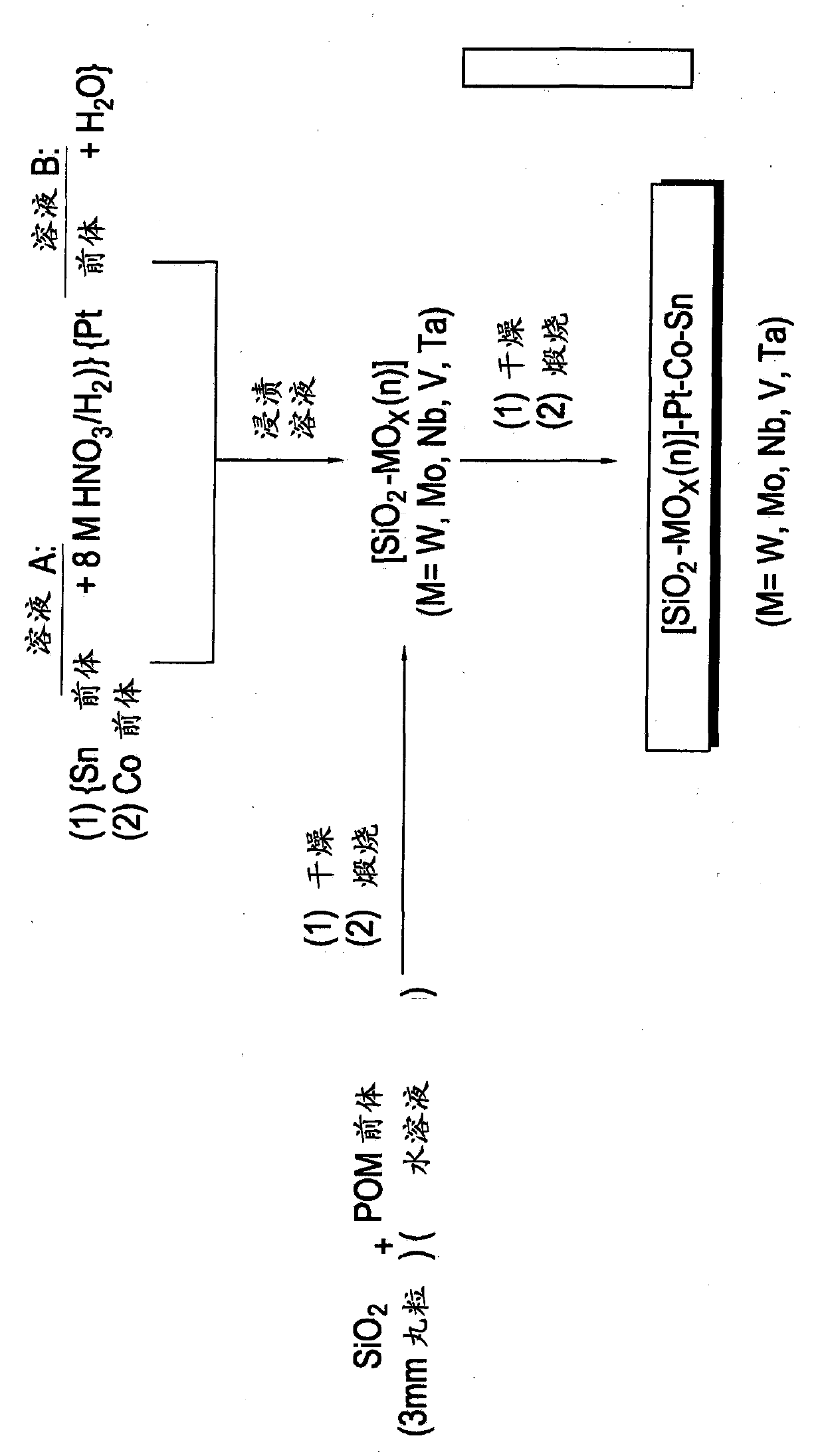

[0041] Catalyst preparation method

[0042] The invention also relates to a process for the preparation of the catalyst. Without being limited by theory, the catalyst preparation method may improve one or more of acetic acid conversion, ester conversion, ethanol selectivity, and overall yield. In one embodiment, the support is modified with one or more support modifiers, and the resulting modified support is subsequently impregnated with a noble metal and one or more active metals to form a catalyst composition. For example, the support can be impregnated with a support modifier solution comprising a support modifier precursor and optionally one or more active metal precursors to form a modified support. After drying and calcination, the resulting modified support is impregnated with a second solution comprising a noble metal precursor and optionally one or more active metal precursors, followed by drying and calcination to form the final catalyst.

[0043] In this embodimen...

Embodiment 1-8

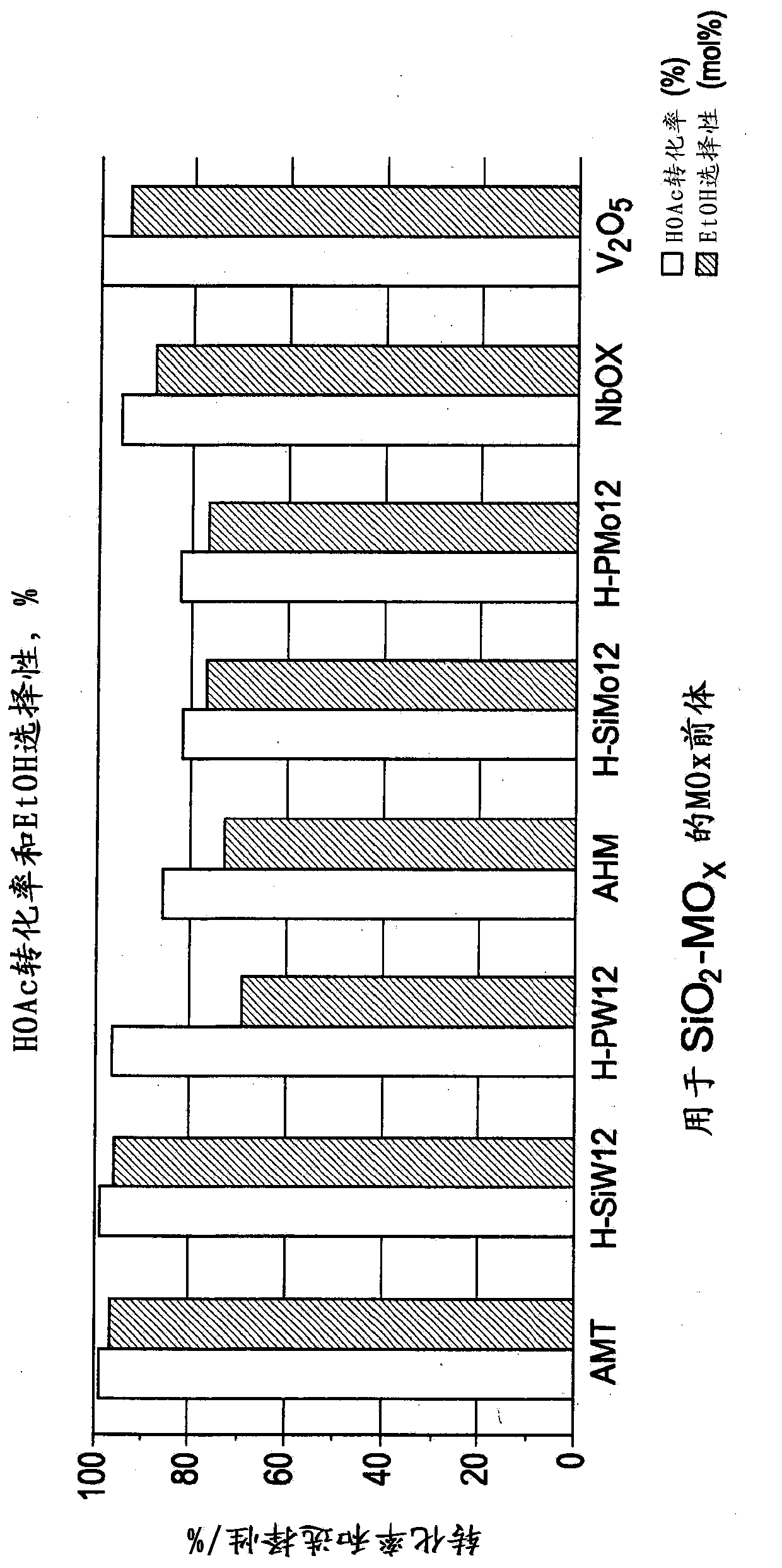

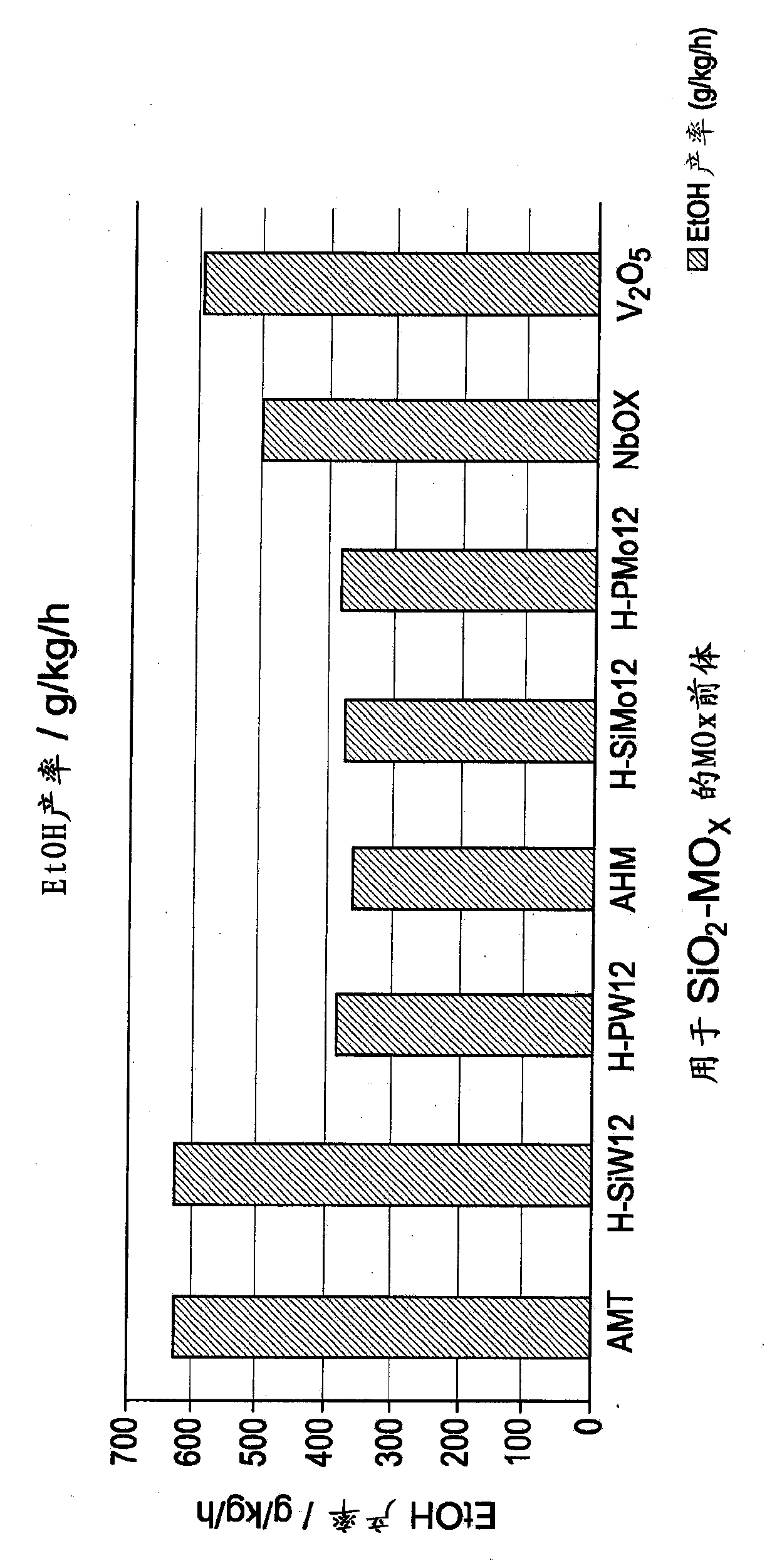

[0105] Eight platinum / tin / cobalt catalysts were prepared using different support modifiers in Examples 1-8. The resulting catalyst was then tested with the mixed feedstock in a hydrogenation unit. In Table 2 the catalyst compositions of Examples 1-8 are provided.

[0106]

[0107] Overview of catalyst preparation.

[0108] Using high surface area (HSA) commercial SiO 2 Support (HSASS #61138, 3 mm pellets, NorPro) was used as starting material for transition metal oxide modified supports. In general, catalyst supports are prepared by impregnating SiO with aqueous solutions of the corresponding W, Mo, Nb, or V polyoxometalate (POM) precursors (see Experimental Section). 2 The extrudate was then dried at 120°C and calcined at 550°C in air. Metal-supported catalysts were obtained by single-step incipient wetness impregnation using aqueous solutions of Sn, Co, and Pt in dilute nitric acid and metal oxide-modified silica supports.

[0109][SiO 2 -MO x (n)] catalyst support...

Embodiment 1

[0115] Example 1: SiO 2 -WO 3 (12). For this preparation, 176.0 g SiO 2 Vehicle (Norpro, 3mm pellets). By dissolving 25.504g (8.63mmol) ammonium metatungstate hydrate (AMT) in 250mL deionized H 2 Prepare the impregnation solution in O. The support was then impregnated using the incipient wetness technique and the material was dried using a rotary evaporator followed by drying overnight at 120°C under circulating air. The dried material was then calcined at 550°C / air for 6 hours. Yield: ~200 g light yellow extrudate. Noble metals and active metals were then impregnated onto the modified support according to the catalyst preparation procedure described below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com