High pressure gas discharge lamp 750khz driving method and circuit

A technology of high-pressure gas and discharge lamps, which is applied to electric light sources, electrical components, lighting devices, etc., can solve the problems of poor temperature characteristics of the excitation magnetic ring, affecting startup, and difficulty in debugging, etc., to achieve extended life, less power loss, and effective Good for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further illustrate the method of the present invention, a preferred embodiment of the present invention will now be described in detail. However, the embodiment is only for illustration and explanation, and cannot be used to limit the scope of patent protection of the present invention.

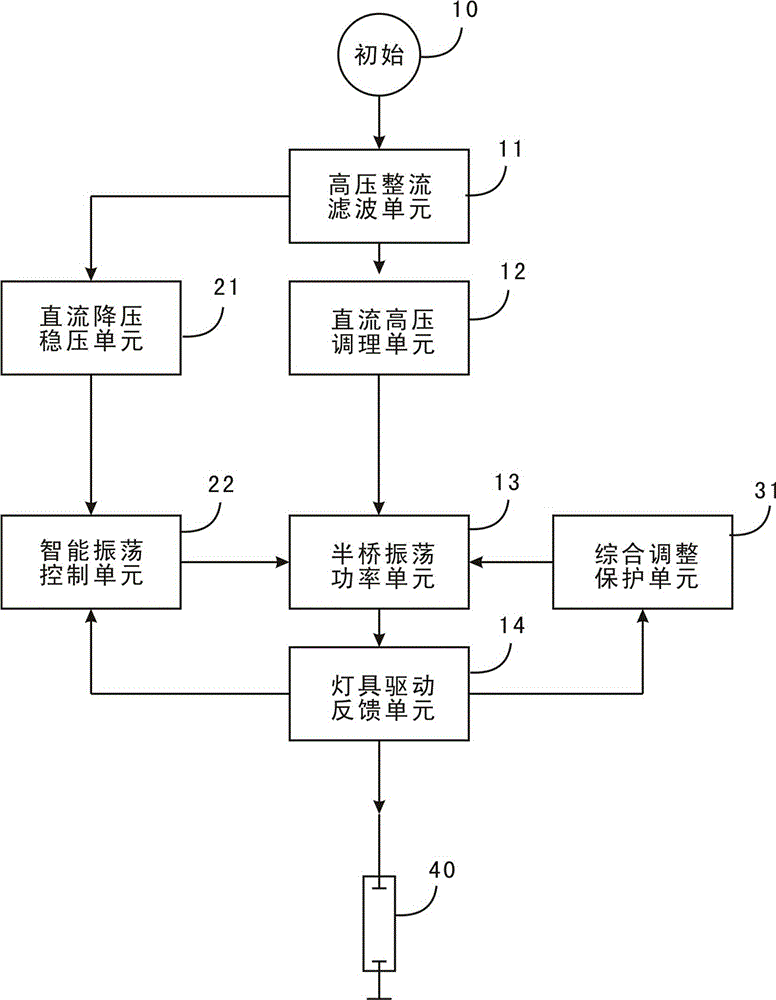

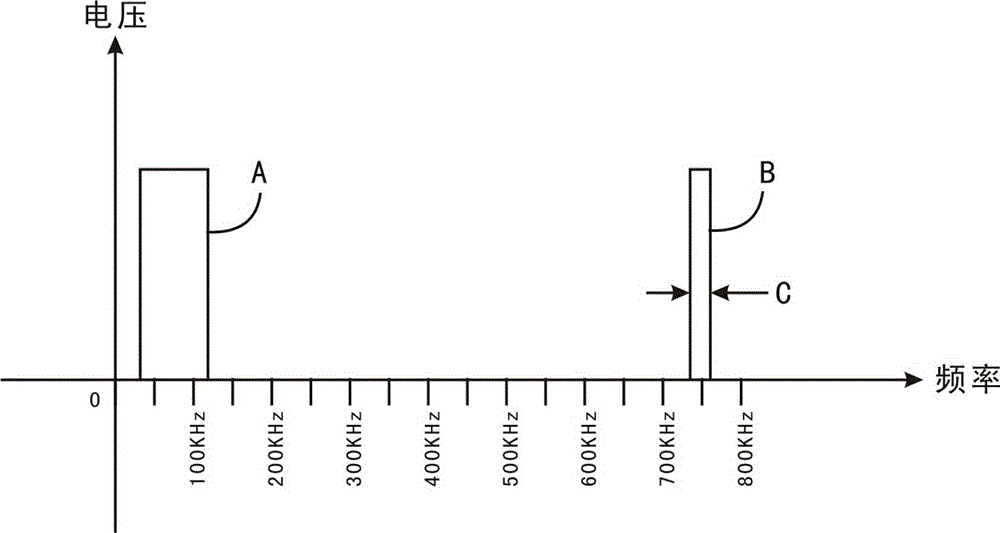

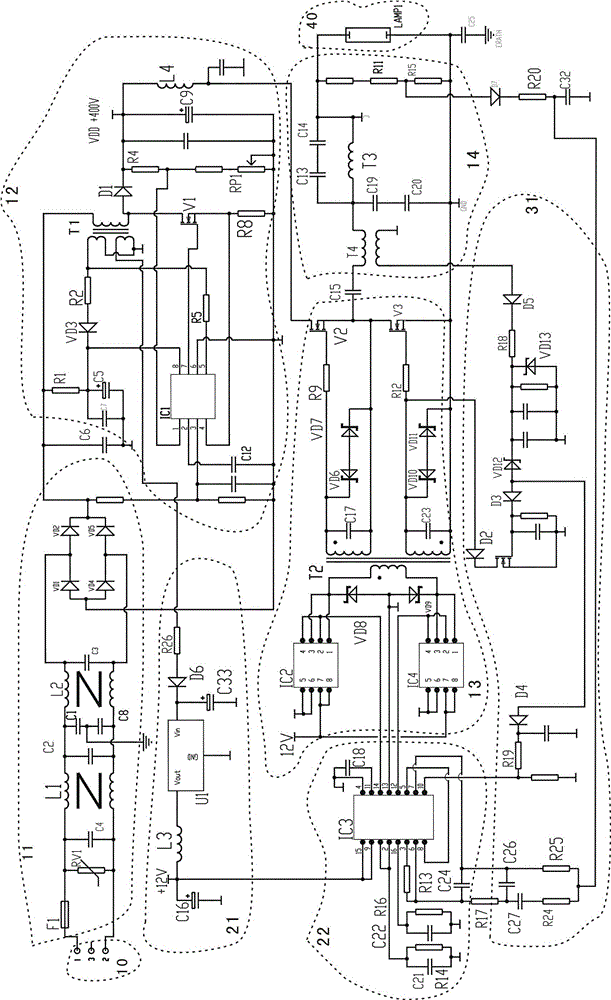

[0042] Such as Figure 1 ~ Figure 3 A method for driving a high-pressure gas discharge lamp at 750KHz is shown, and the method includes the following steps:

[0043] In the first step, a high-voltage rectification and filtering unit 11 is first set, and the initial terminal 10 is directly connected to

[0044] The alternating current is introduced, and rectified and filtered to be a DC high voltage, and its output is ready to be connected to the DC high voltage conditioning unit 12;

[0045] In the second step, a DC step-down voltage regulator unit 21 is connected to the inductance T1 of the DC high-voltage conditioning unit 12, and the DC step-down voltage regulator unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com