Intelligent management method for numerical control machine tool

The technology of a numerical control machine tool and a management method is applied to the real-time running state monitoring of the machine tool, and the use of an identity card to control the servo enablement field of the numerical control machine tool can solve the problems of reducing equipment utilization, increasing maintenance costs, and not having a numerical control system, and achieving practicality. Strong, easy-to-promote, and statistically accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

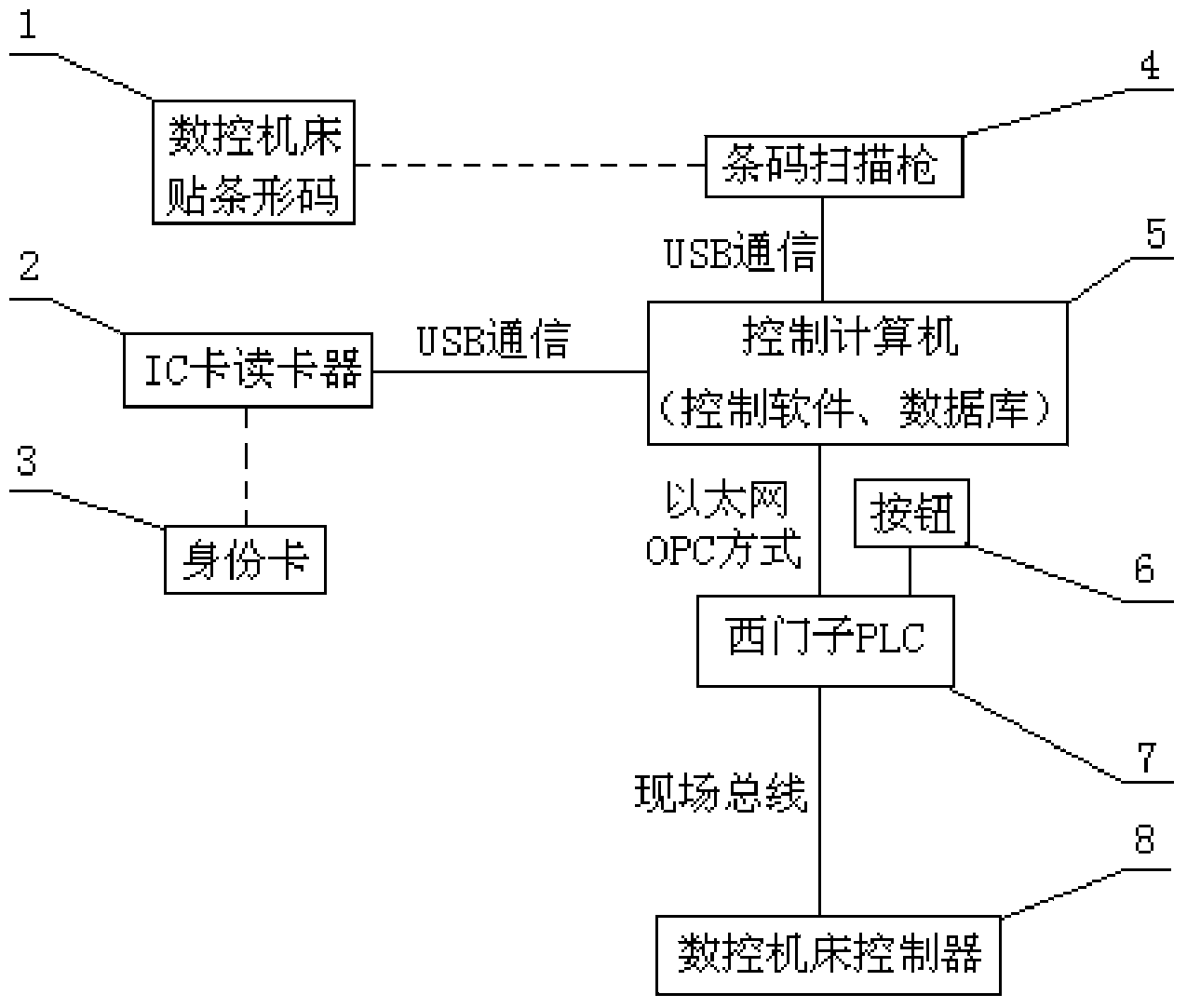

[0020] Such as figure 1 As shown, the equipment adopted in the intelligent management method of CNC machine tools of the present invention includes: CNC machine tools 1 with barcodes, IC card readers 2, identity cards 3, barcode scanning guns 4, control computers 5 (including control software and background database), button 6, Siemens PLC7, CNC machine tool controller 8; IC card reader 2 and barcode scanner 4 communicate with control computer 5 through USB, and control computer 5 and Siemens PLC7 adopt Ethernet communication based on OPC. Profibus DP field bus communication is adopted between Siemens PLC7 and CNC machine tool controller 8 .

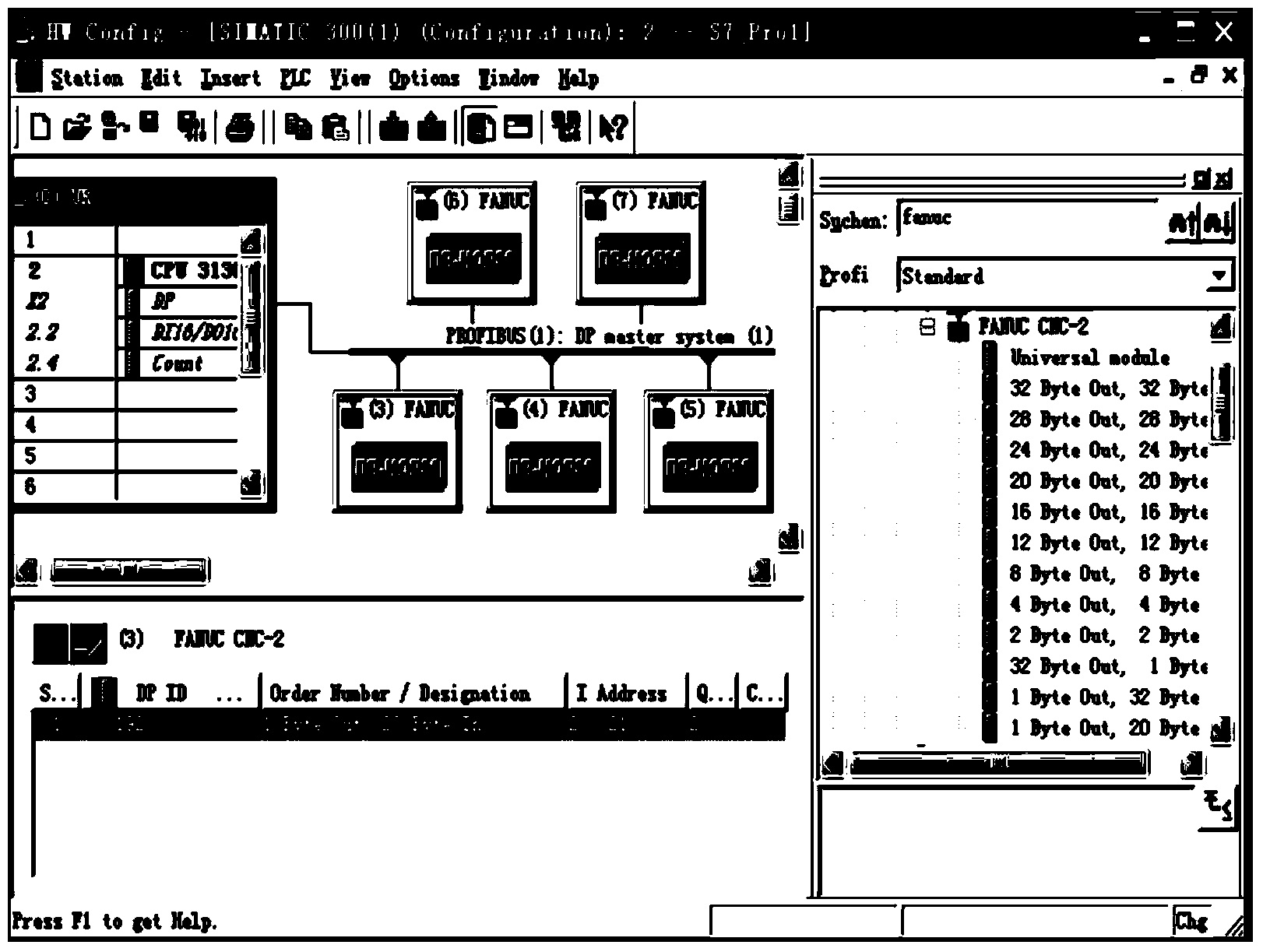

[0021] Said Siemens PLC refers to Siemens S7300 / 400PLC configured with Profibus DP module or interface, Ethernet module or interface. The numerical control machine tool controller refers to a numeric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com