Hydraulic test system of railway tamping device

A hydraulic test, railway technology, applied in the field of hydraulic power station, can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

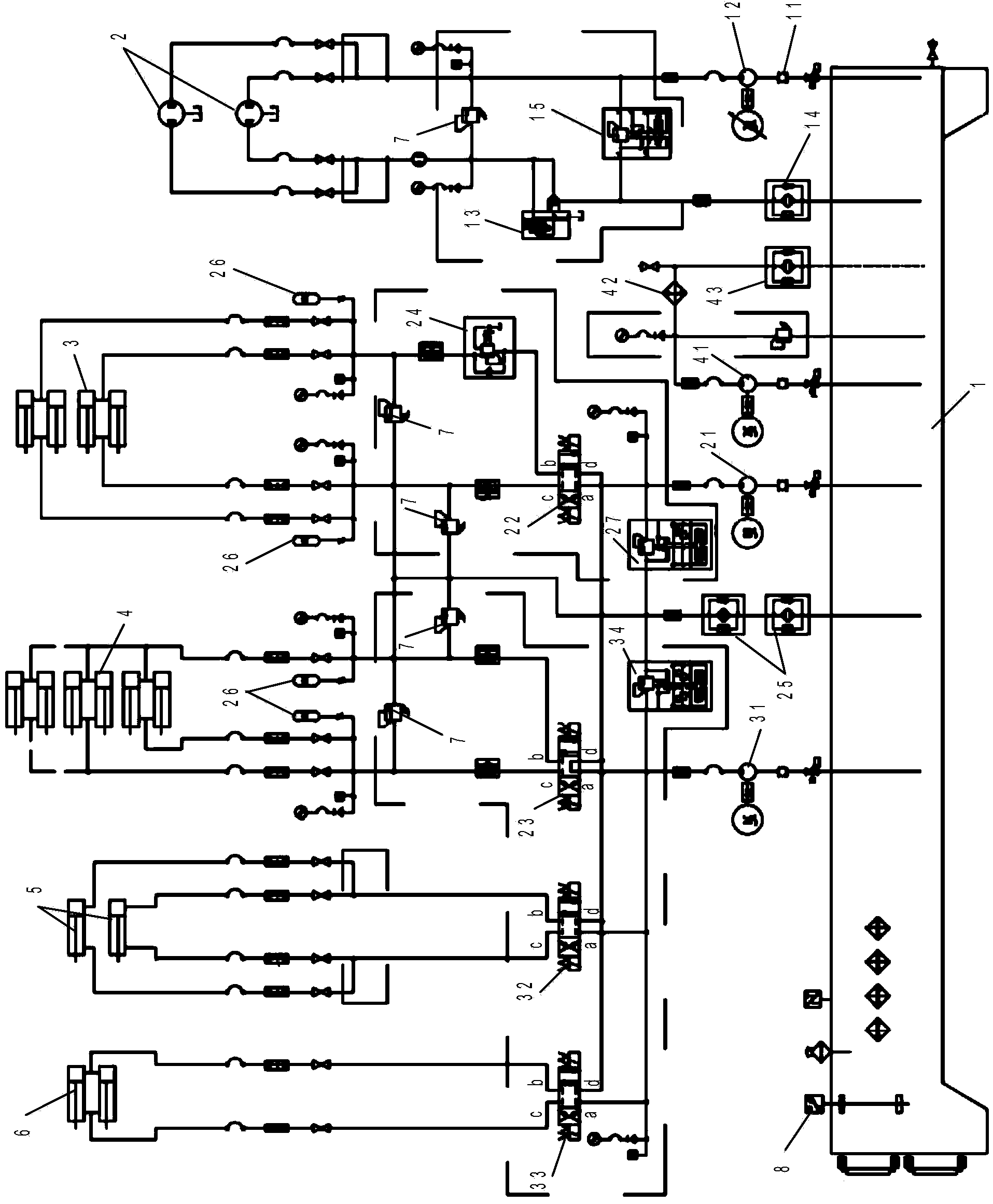

[0017] The hydraulic test system of railway tamping device of the present invention is as figure 1 As shown, it includes a fuel tank 1 and a load motor test circuit. The load motor test circuit mainly includes a shock absorber 11, a first oil suction pump 12, and a logic valve 13. The input end of the shock absorber 11 is connected to the fuel tank 1, and the output end is connected to the second One oil suction pump 12 is connected; the first oil suction pump 12 can be an internal meshing gear pump, and it is driven by a 37kw secondary frequency conversion motor, and the output end of the first oil suction pump 12 is respectively connected to the load motor of the tamping device Group 2 is connected; the input end of logic valve 13 is respectively connected with the output end of load motor group 2, and the output end of logic valve 13 is connected to oil tank 1 through the first oil return filter, and logic valve 13 is powered on and cut off when it is powered off. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com