Production method of monascus vinegar rich in lovastatin

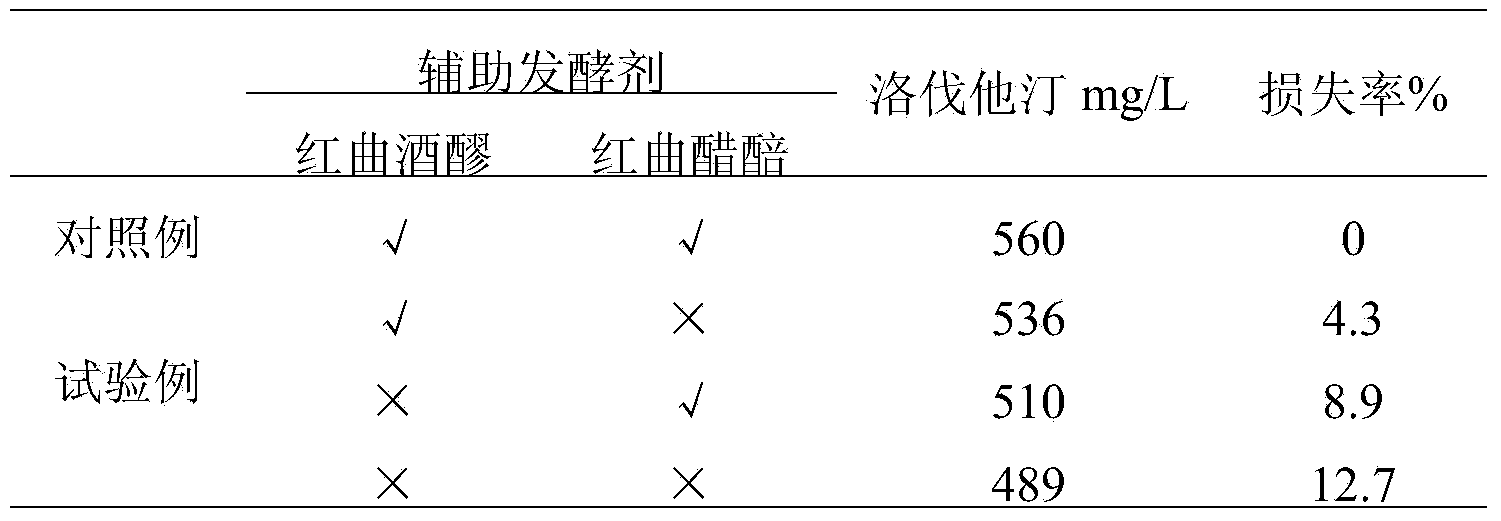

A production method and Tinghong technology are applied in the production field of red yeast vinegar rich in lovastatin, and can solve the problems that the intake dose cannot reach lipid-lowering health care, the intake of vinegar is restricted, and the content of lovastatin is low. , to achieve the effect of excellent color, increased content and rich aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

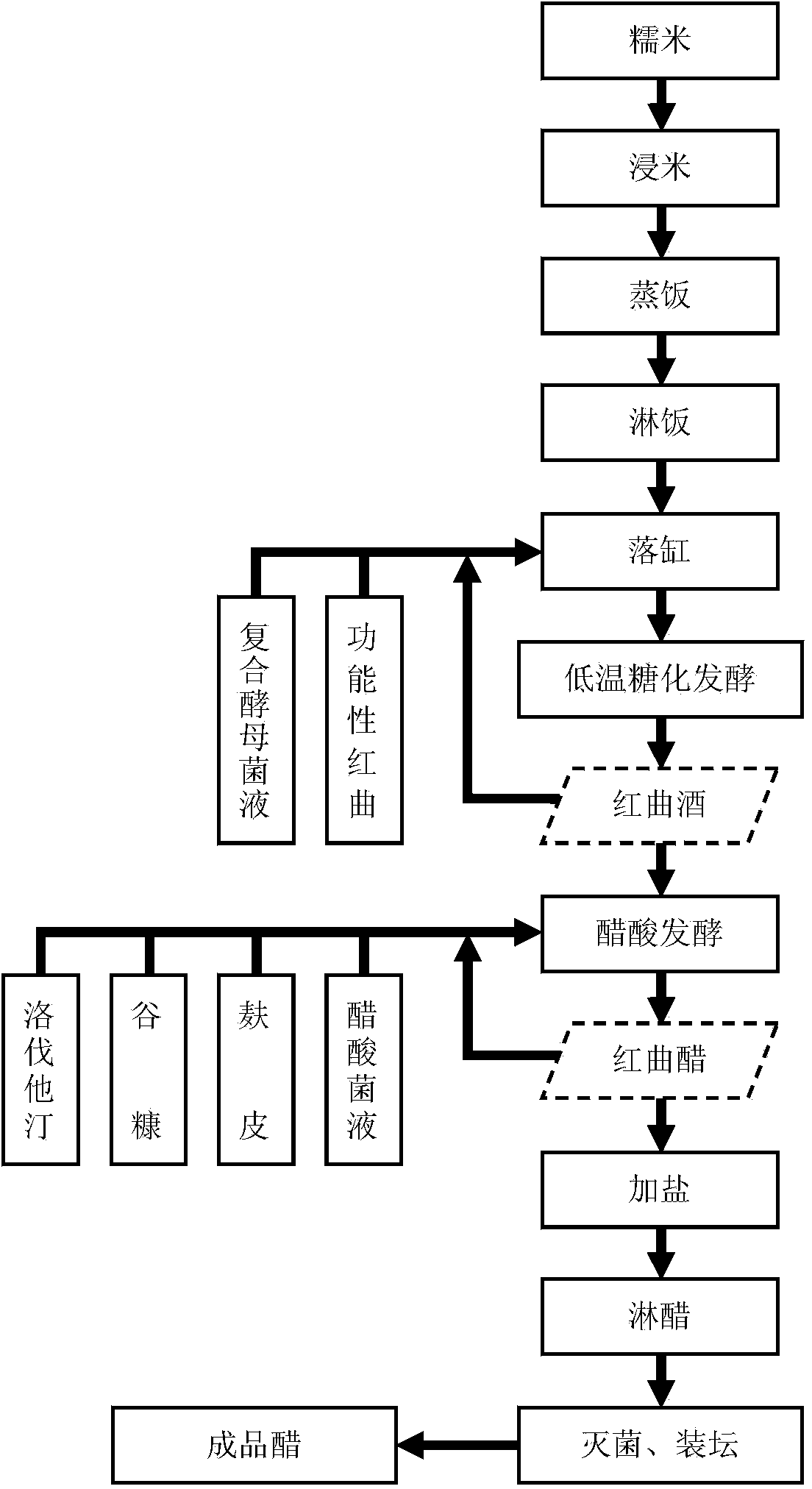

Method used

Image

Examples

Embodiment 1

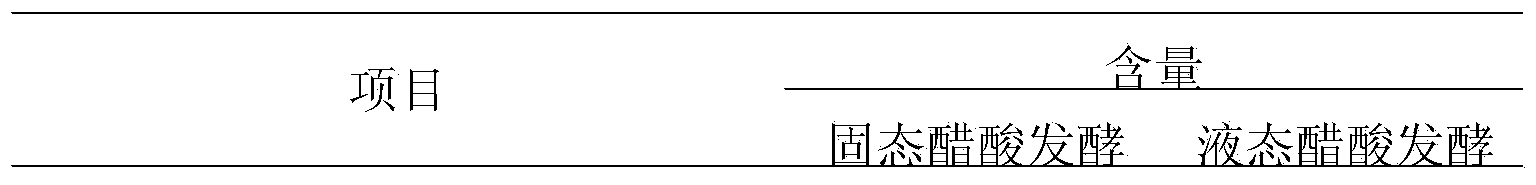

[0032]Soak the weighed glutinous rice, steam it, and knead the rice by hand, the inside and outside are consistent, and there is no white heart; rinse with clean water according to the ratio of glutinous rice: water = 1:1.5, and the temperature of the rice after washing is 32-34°C; Drain the cold glutinous rice and drain the remaining water, pour it into the large tile tank that has been washed and steam sterilized in batches, and mix the compound yeast liquid, the fermented red yeast rice wine fermented by the previous batch, and the functional red yeast rice ( Soak in 10 times the water for 6 hours in advance) respectively drop into the tank according to 1.0%, 15% and 20% of the raw materials, mix well with the glutinous rice, no need to add water, the temperature of the product in the tank should be 26-28°C; 12 hours after dropping into the tank, The temperature of the product starts to rise, and then it should be stirred in time to keep the temperature of the product at 28-...

Embodiment 2

[0034] Soak the weighed glutinous rice, steam it, and knead the rice by hand, the inside and outside are consistent, and there is no white heart; rinse with clean water according to the ratio of glutinous rice: water = 1:2.0, and the temperature of the rice after washing is 30-32°C; Drain the cold glutinous rice and drain the remaining water, pour it into the large tile tank that has been washed and steam sterilized in batches, and mix the compound yeast liquid, the fermented red yeast rice wine fermented by the previous batch, and the functional red yeast rice ( Soak with 10 times of water in advance for 8 hours) respectively drop into the vat according to 1.2%, 20% and 25% of the raw materials, mix well with the glutinous rice, no need to add water, the product temperature in the vat is required to be 26-28°C; 10 hours after the vat, The temperature of the product starts to rise, and then it should be stirred in time to keep the temperature of the product at 28-30°C. Ferment ...

Embodiment 3

[0036] Soak the weighed glutinous rice, steam it, and knead the rice by hand, the inside and outside are consistent, and there is no white heart; rinse with clean water according to the ratio of glutinous rice: water = 1:2.0, and the temperature of the rice after washing is 30-32°C; Drain the cold glutinous rice and drain the remaining water, pour it into the large tile tank that has been washed and steam sterilized in batches, and mix the compound yeast liquid, the fermented red yeast rice wine fermented by the previous batch, and the functional red yeast rice ( Soak with 10 times the water in advance for 8 hours) and drop into the vat according to 1.5%, 25%, and 30% of the raw materials respectively, and mix well with the glutinous rice without adding water. The product temperature in the vat should be 26-28°C; The temperature of the product starts to rise, and then it should be stirred in time to keep the temperature of the product at 28-30°C, and it will be fermented for 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com