Temperature-control released snow-melting agent microcapsule and preparation method thereof

A snow-melting agent and microcapsule technology, which is applied in the field of temperature-controlled release-type snow-melting agent microcapsules and their preparation, can solve the problems of inability to take into account the snow-melting effect and the durability of snow-melting, and the inability to control the release time of snow-melting substances, so as to promote long-term snow-melting. High deicing and snow melting efficiency and accumulation suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of deicing agent microcapsules

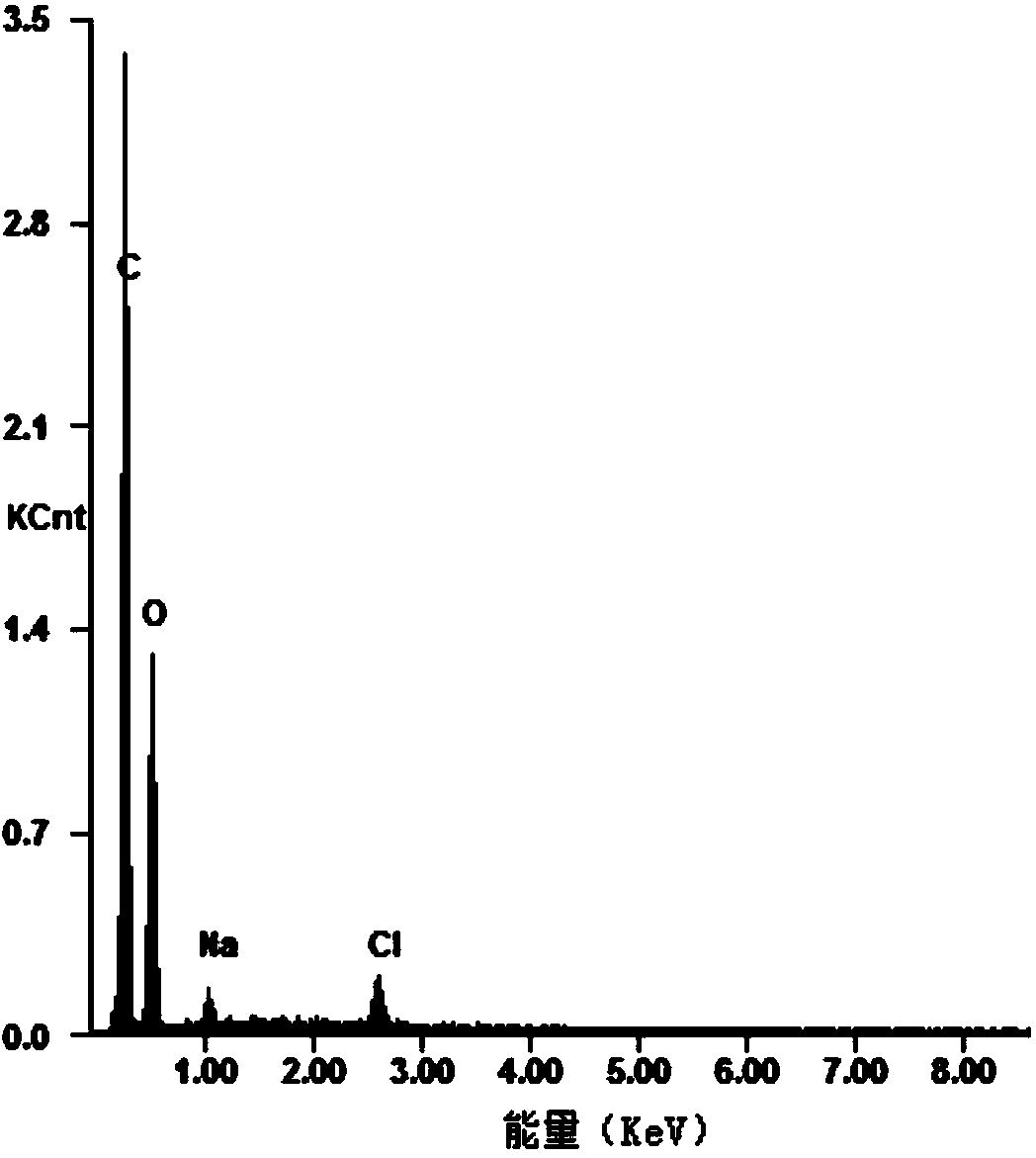

[0029] Dissolve 0.5 g of polystyrene with a number average molecular weight of 40,000 in 30 g of cyclohexane, add 0.9 g of sodium chloride and 0.1 g of polyethylene glycol 4000 that have been ground through a 100 mesh sieve, stir and disperse evenly, and then pour Add 3g Span-80 into 150g methyl silicone oil, stir and fully emulsify to form a stable emulsion, evaporate the cyclohexane in the emulsion under reduced pressure at room temperature, filter with suction, wash with petroleum ether, dry at room temperature to obtain snowmelt agent microcapsules.

[0030] 2. Preparation of temperature-controlled release deicing agent microcapsules

[0031] Dissolve 0.15g of benzophenone and 0.1g of N-methyl-N-sec-butylacrylamide in 5g of absolute ethanol, then add 1g of deicing agent microcapsules, stir and mix evenly, heat at 50°C for 1 hour, and cool to At room temperature, then add 5g of absolute ethanol, irradiate with 500W ul...

Embodiment 2

[0037] 1. Preparation of deicing agent microcapsules

[0038] Completely dissolve 0.1g of polystyrene with a number average molecular weight of 50,000 in 20g of cyclohexane, add 0.9g of magnesium nitrate and 0.1g of sodium gluconate that have been ground and passed through a 150-mesh sieve, stir and disperse evenly, and then pour 100g of formosan Add 2g of Span-80 to base silicone oil, stir and fully emulsify to form a stable emulsion, evaporate the cyclohexane in the emulsion under reduced pressure at room temperature, filter with suction, wash with petroleum ether, and dry at room temperature to obtain deicing agent microcapsules .

[0039] 2. Preparation of temperature-controlled release deicing agent microcapsules

[0040] Dissolve 0.1g of benzophenone and 0.05g of N-methyl-N-sec-butylacrylamide in 3g of absolute ethanol, then add 1g of deicing agent microcapsules, stir and mix evenly, pretreat at 50°C for 0.5 hours, and cool to normal temperature, then add 3g of absolut...

Embodiment 3

[0042] 1. Preparation of deicing agent microcapsules

[0043] Completely dissolve 1g of polystyrene with a number average molecular weight of 40,000 in 40g of cyclohexane, add 0.9g of calcium chloride and 0.1g of acrylamide that have been ground and passed through a 200-mesh sieve, stir and disperse evenly, and then pour 200g of methyl Add 5g of Span-80 to the silicone oil, stir and fully emulsify to form a stable emulsion, evaporate the cyclohexane in the emulsion under reduced pressure at room temperature, filter with suction, wash with petroleum ether, and dry at room temperature to obtain deicing agent microcapsules.

[0044] 2. Preparation of temperature-controlled release deicing agent microcapsules

[0045] Dissolve 0.3g of benzophenone and 0.3g of N-methyl-N-sec-butylacrylamide in 10g of absolute ethanol, then add 1g of deicing agent microcapsules, stir and mix evenly, and pretreat at 50°C for 0.5 hours , cooled to normal temperature, then added 10g of absolute ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com