Ceramic microcrystal abrasive powerful grinding wheel and processing method thereof

A technology of ceramic microcrystalline abrasive and processing method, which is applied in the field of grinding wheels, can solve the problems of large precision error, small processing precision, small precision error, etc., and achieve the effects of small precision error, high processing precision and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below in combination with specific embodiments.

[0033] The emery wheel of the present invention comprises a central reinforcement part and a grinding use part, and the parts by weight of each raw material of the central reinforcement part are:

[0034]

[0035]

[0036] The parts by weight of each raw material of the part used in the grinding is:

[0037]

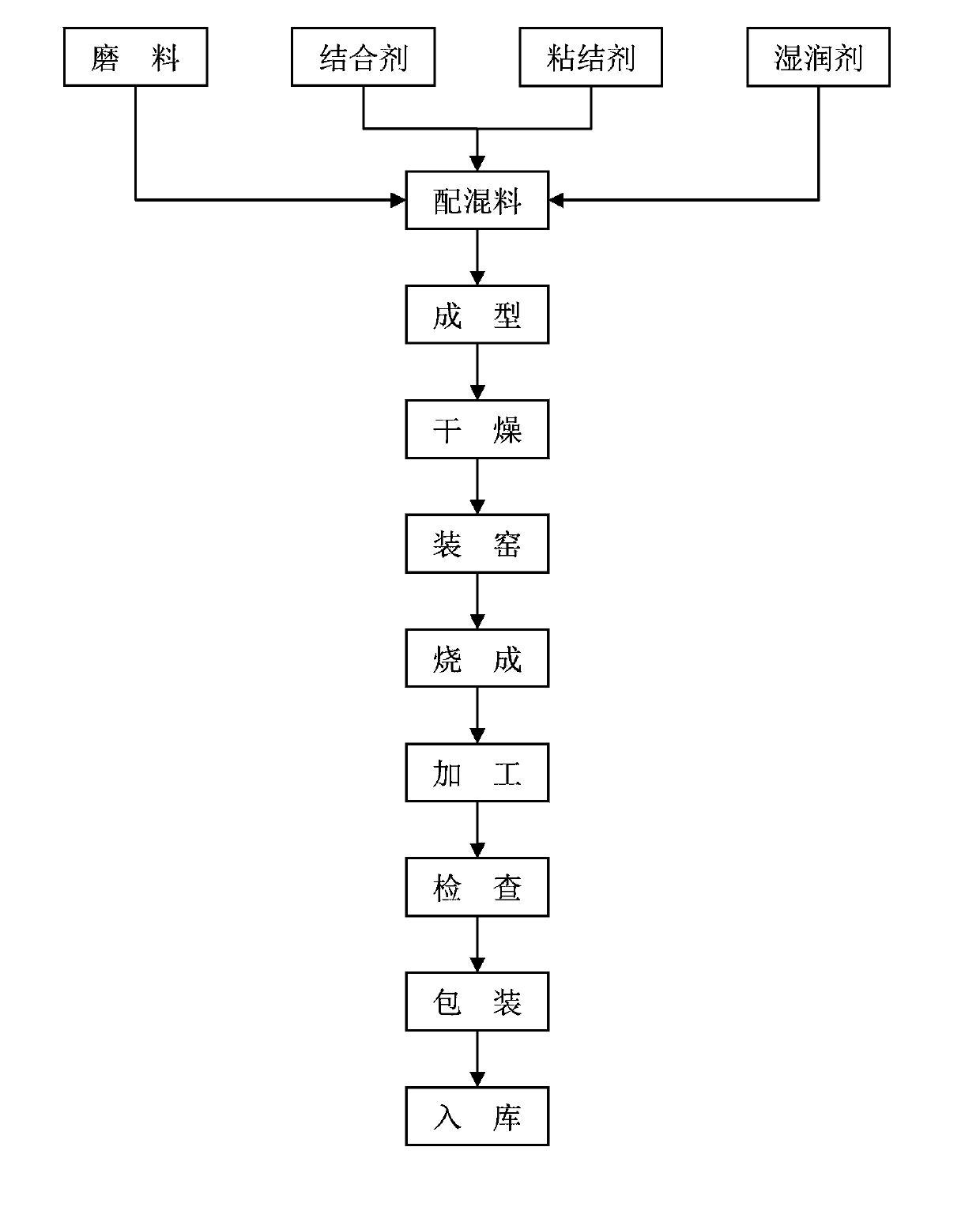

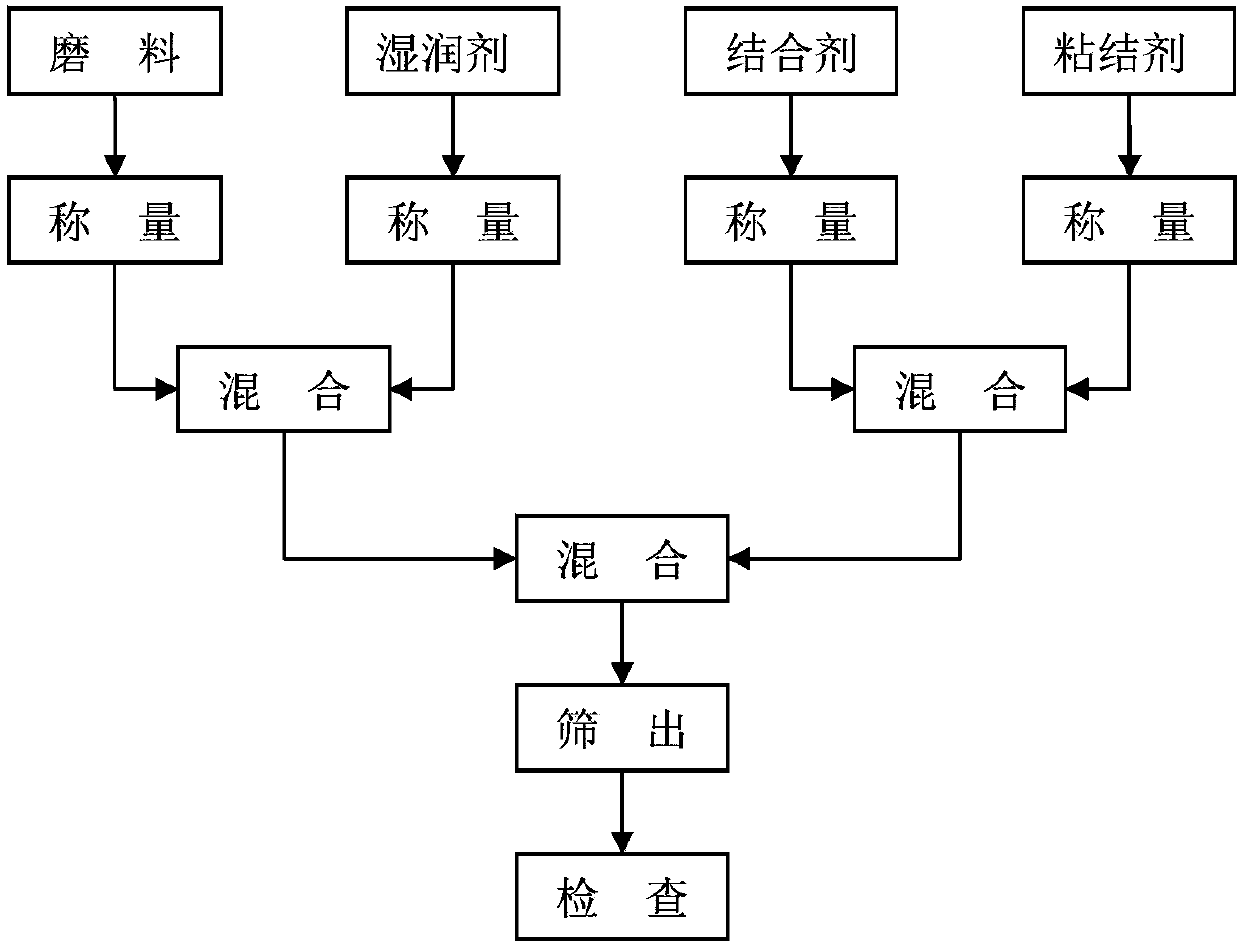

[0038] When the present invention is made as figure 1 , figure 2 The process shown is carried out, and the specific operation is as follows:

[0039] 1) Mixing material: first put the abrasive into the mixing pot, then add the weighed wetting agent, start the agitator, and mix well; while mixing the abrasive and wetting agent, put the prepared binder and binder well mixed. After the abrasive and wetting agent have been mixed for the specified time, slowly pour in the mixture of binder and binder that has been mixed evenly, and after mixing for the speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com