Flat position single-seam symmetrical welding method for orthotropic plate U-shaped rib corner welding seam robot

An orthotropic plate and fillet weld technology, used in welding equipment, welding equipment, arc welding equipment, etc., can solve the problem of difficulty in maintaining consistency in appearance molding, U-shaped rib fillet weld quality fluctuation, and weld penetration. Depth instability and other problems, to achieve the effect of good appearance, reduce welding material consumption, reduce welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

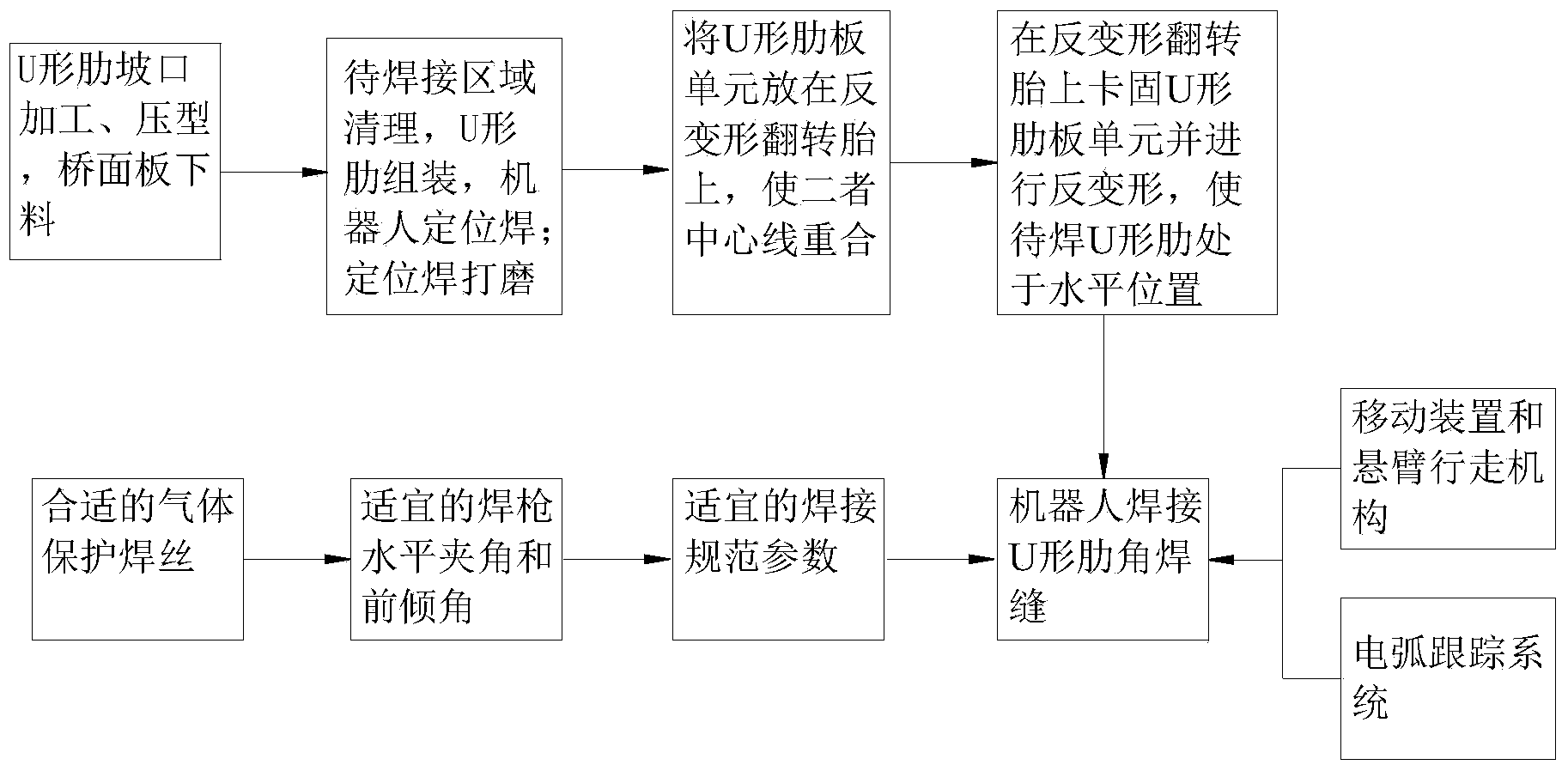

[0030] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing, basic welding steps are as follows:

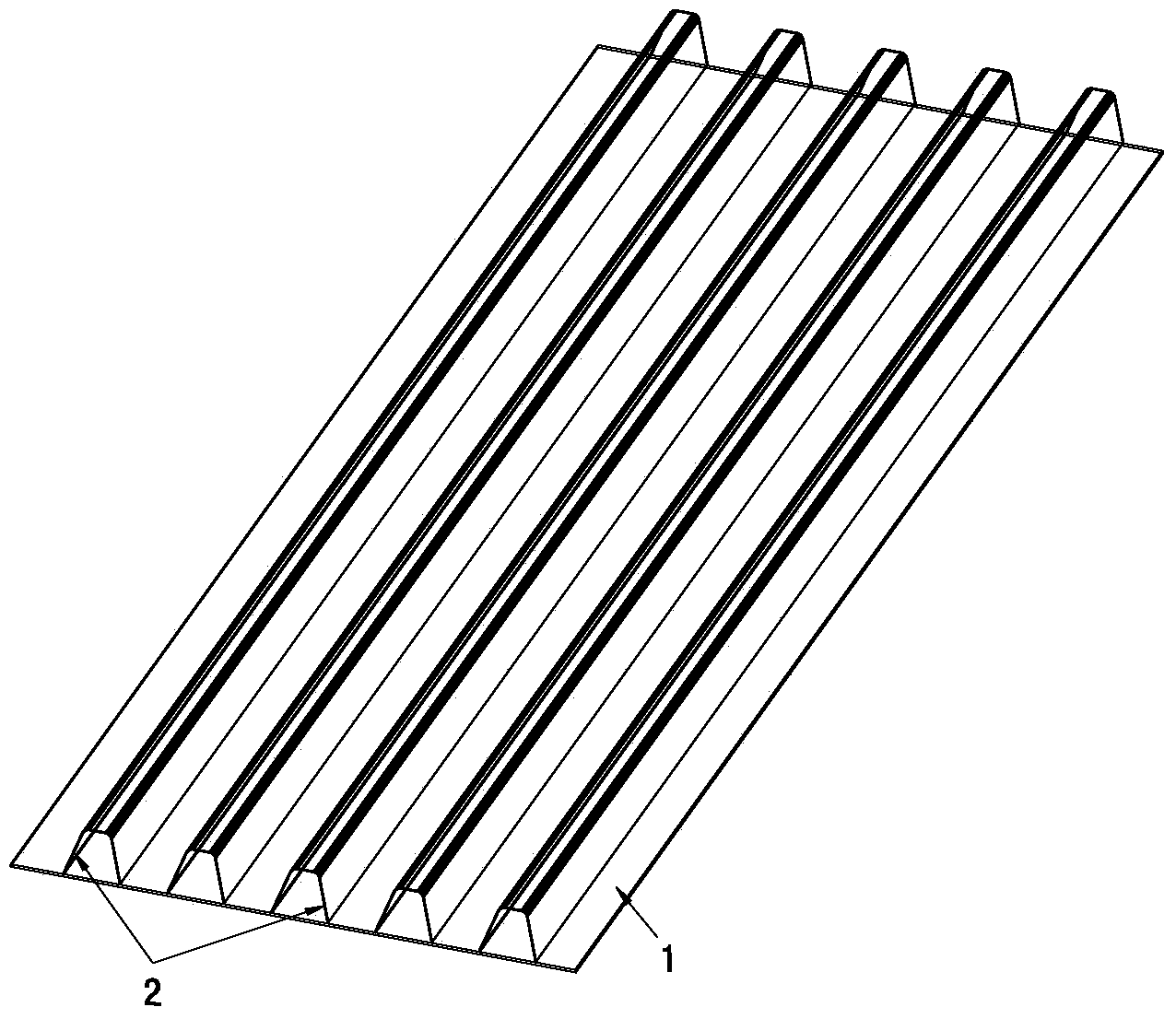

[0031] A. U-shaped rib groove processing, pressing, blanking of bridge deck, and assembly into U-shaped rib plate unit.

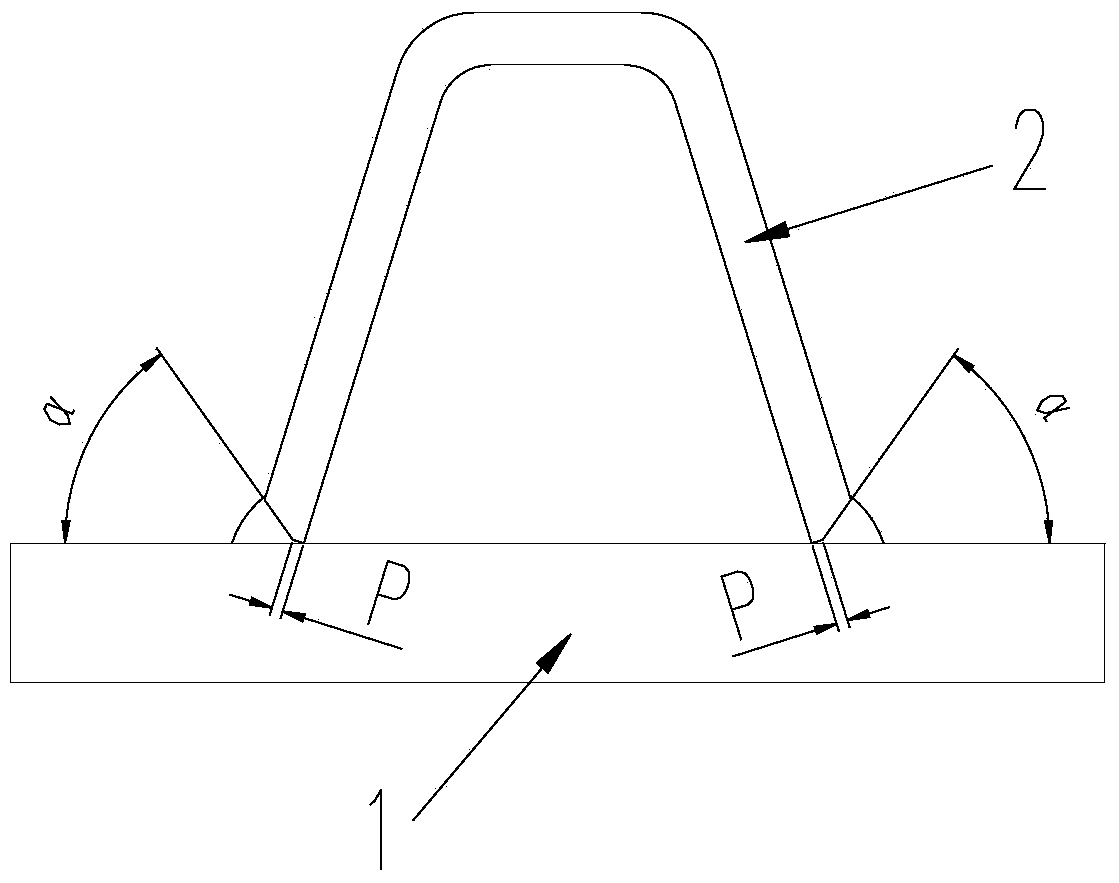

[0032] A-1. U-shaped rib groove processing, profiling, and blanking of the bridge deck: After the U-shaped rib is flattened with a steel plate, it is blanked according to the width and length of the U-shaped rib and a certain amount of processing is reserved. Side milling and fillet weld beveling, and then the steel plate is pressed on the forming machine to form U-shaped ribs; the bridge deck is rolled flat with steel plates and then unloaded.

[0033] A-2. Clean up the area to be welded and assemble the U-shaped ribs: before assembling the U-shaped ribs, remove the scale, rust, oil, moisture and other welding harmful substances in the area to be welded and the range to be welded on both sides; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com