A magnetic pulse forming device and method for small-diameter flanging holes in aluminum alloy plates

An aluminum alloy sheet material and magnetic pulse forming technology, which is applied in the field of plastic forming manufacturing of sheet metal parts, can solve problems such as the difficulty in obtaining parts that meet the flanged holes, the easily damaged process steps of the processed parts, and the unstable forming quality. It can convert to mechanical energy with high efficiency, solve the problem of low coil life and solve the effect of many process passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

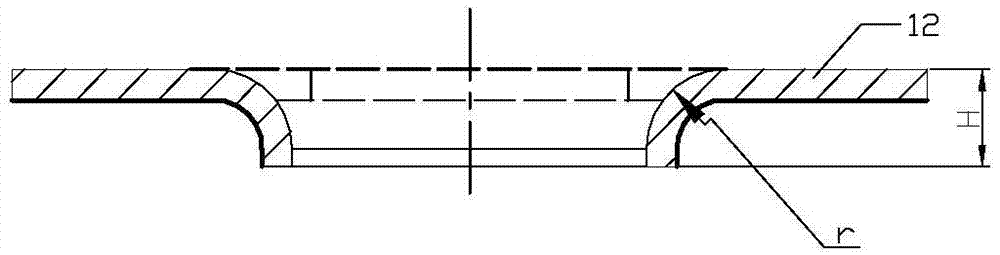

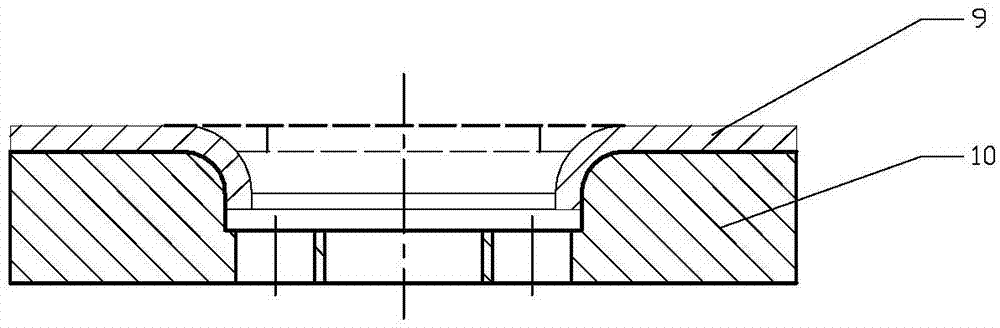

[0014] Specific implementation mode one: as Figure 1 ~ Figure 3 As shown, a magnetic pulse forming device for a small-diameter flanging hole in an aluminum alloy plate according to this embodiment includes a magnetic pulse control circuit 1, an upper platen 3, a magnetic collector limit ring 4, a columnar magnetic collector 7, and a positioning ring 8 , flanging die 10, base plate 11 and solenoid coil; the solenoid coil includes a bobbin 5 and a coil turn 6, and the coil turn 6 is wound into a spiral cylindrical potting in the bobbin 5, and the flanging The die 10 is fixed on the upper end surface of the base plate 11, and the outer wall of the positioning ring 8 is provided with an annular platform 8-1. The annular platform 8-1 divides the positioning ring 8 into upper and lower sections. Inside, the upper part of the positioning ring 8 is set in the columnar magnetic collector 7, the magnetic collector limit ring 4 is arranged on the upper end surface of the columnar magnet...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Note that the magnetic pulse control circuit 1 in this embodiment includes a high-voltage transformer 1-1, a rectifier 1-2, a current limiting resistor 1-3, a high-voltage switch 1-4, a capacitor bank 1-5, and an AC power supply 1-6; One end of the secondary coil 1-1-1 of the high voltage transformer 1-1 is connected to the anode of the rectifier 1-2, the cathode of the rectifier 1-2 is connected to one end of the current limiting resistor 1-3, and the current limiting resistor 1 The other end of -3 is connected with the positive pole of capacitor bank 1-5 and the positive pole of high-voltage switch 1-4, and the negative pole of high-voltage switch 1-4 is as described one output end of magnetic pulse control circuit 1, and the secondary of high-voltage transformer 1-1 The other end of the primary coil 1-1-1 is connected to the power supply ground and the negative pole of the capacitor bank 1-5 and is used as the ot...

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 Note that the width of the longitudinal slit 7-1 in this embodiment is 0.3-1mm. This narrow slit is used to cut off the induced current to form a loop directly on the surface of the outer wall of the magnet collector, so that the magnetic field in the gap between the inner surface of the coil and the outer wall of the magnet collector can be transmitted to the working area of the magnet collector and the gap between the aluminum alloy plate. If the gap is too small, it is difficult to implement gap insulation treatment. On the contrary, the loss of magnetic field energy in the gap will increase, and the amplitude of the magnetic field force will be reduced, which is not conducive to the effect of flanging. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com