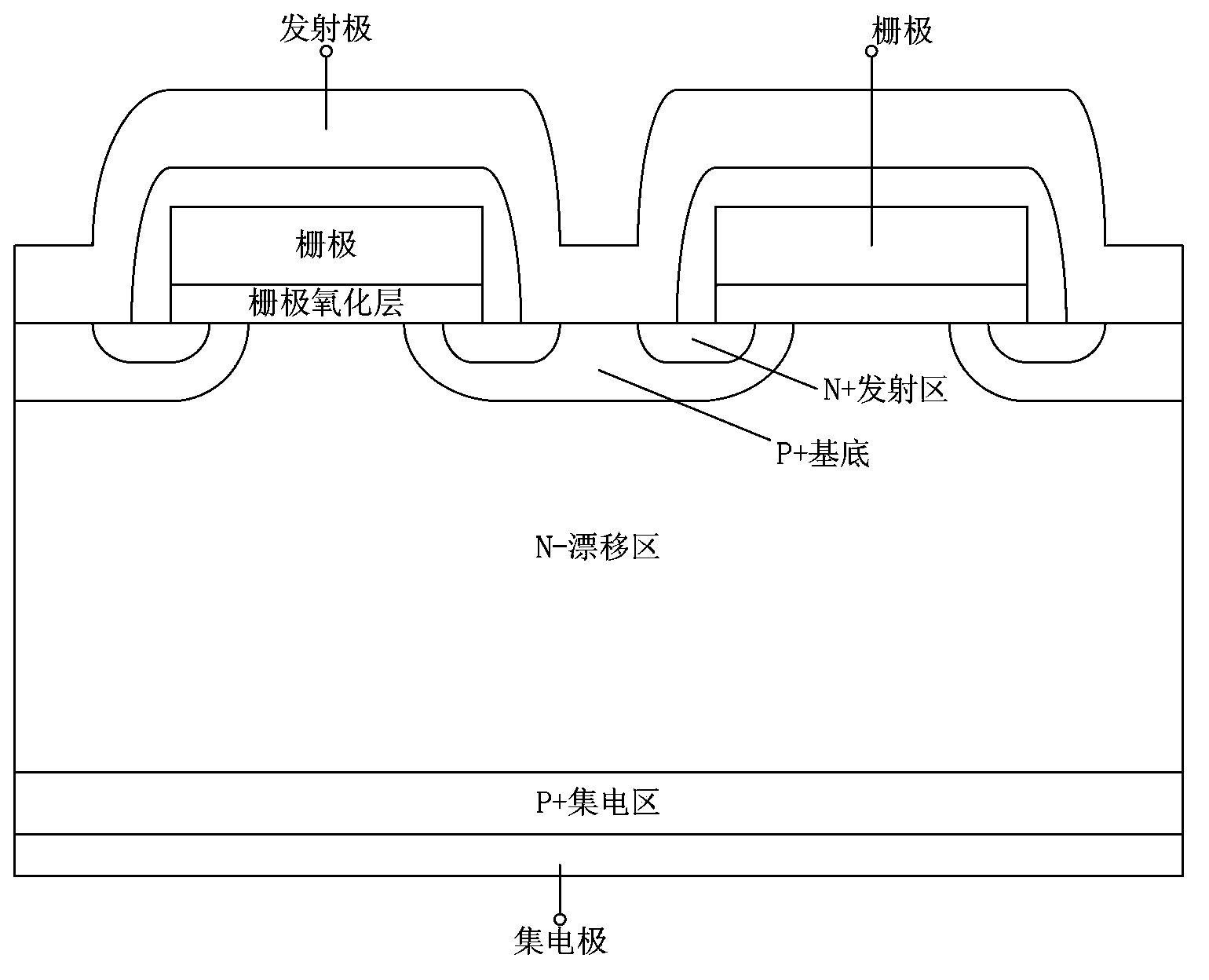

Punch-through IGBT and manufacturing method thereof

A production method and a punch-through technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve difficult problems and achieve the effects of reducing process difficulty, increasing thickness, and reducing the risk of splinters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As mentioned in the background art section, in the prior art, there is a problem of high manufacturing difficulty when manufacturing punch-through IGBTs.

[0039] The inventors have found that there are two methods for fabricating the punch-through IGBT in the prior art: one is to fabricate the punch-through IGBT through an epitaxial process; the other is to fabricate the punch-through IGBT through a diffusion or ion implantation process.

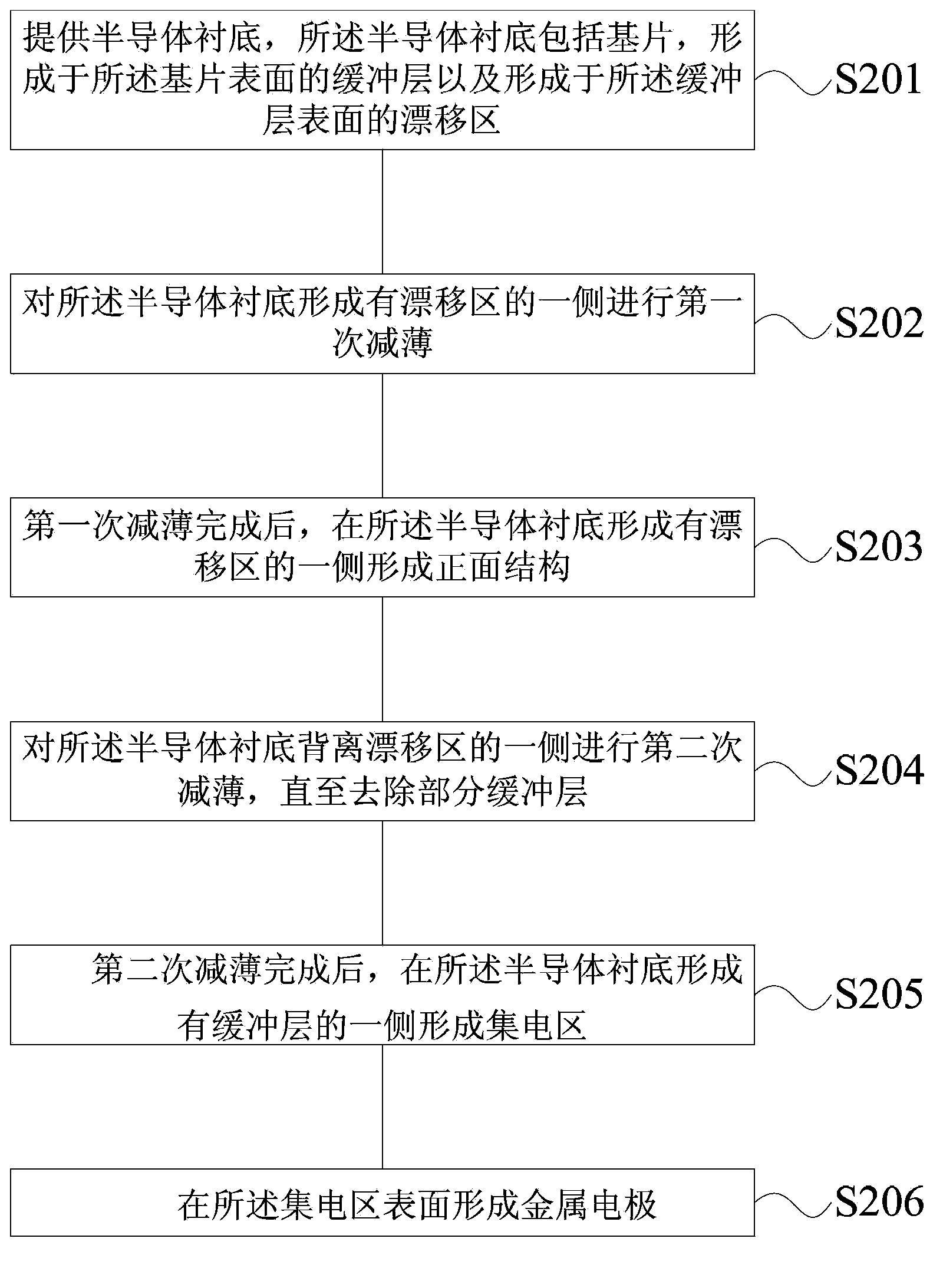

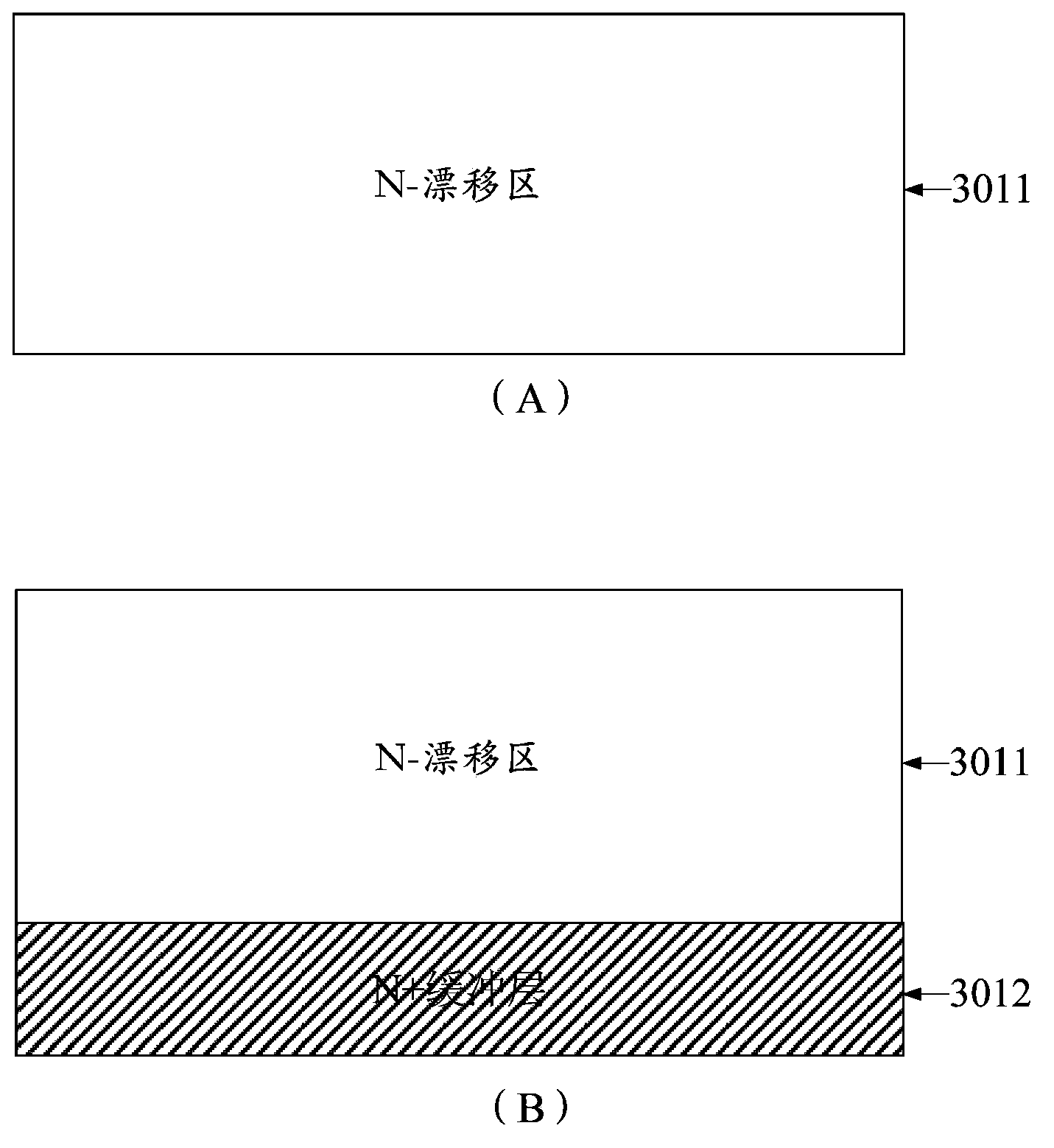

[0040] For the method of making punch-through IGBT by epitaxial process, it specifically includes: providing a P-type silicon substrate, epitaxially growing an N-type buffer layer on the surface of the P-type silicon substrate; and then epitaxially growing an N-type buffer layer on the surface of the N-type buffer layer Drift region; then make a front structure on the surface of the N-type drift region; finally thin the back of the P-type silicon substrate to form a collector region. The drift region and buffer layer in this method a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com