Method for sealing glass lamp tube and metal electrode

A glass lamp tube and metal electrode technology, applied in the field of electric light source, can solve the problems of relying on the technical level of melting personnel, slow air leakage connection strength, low mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

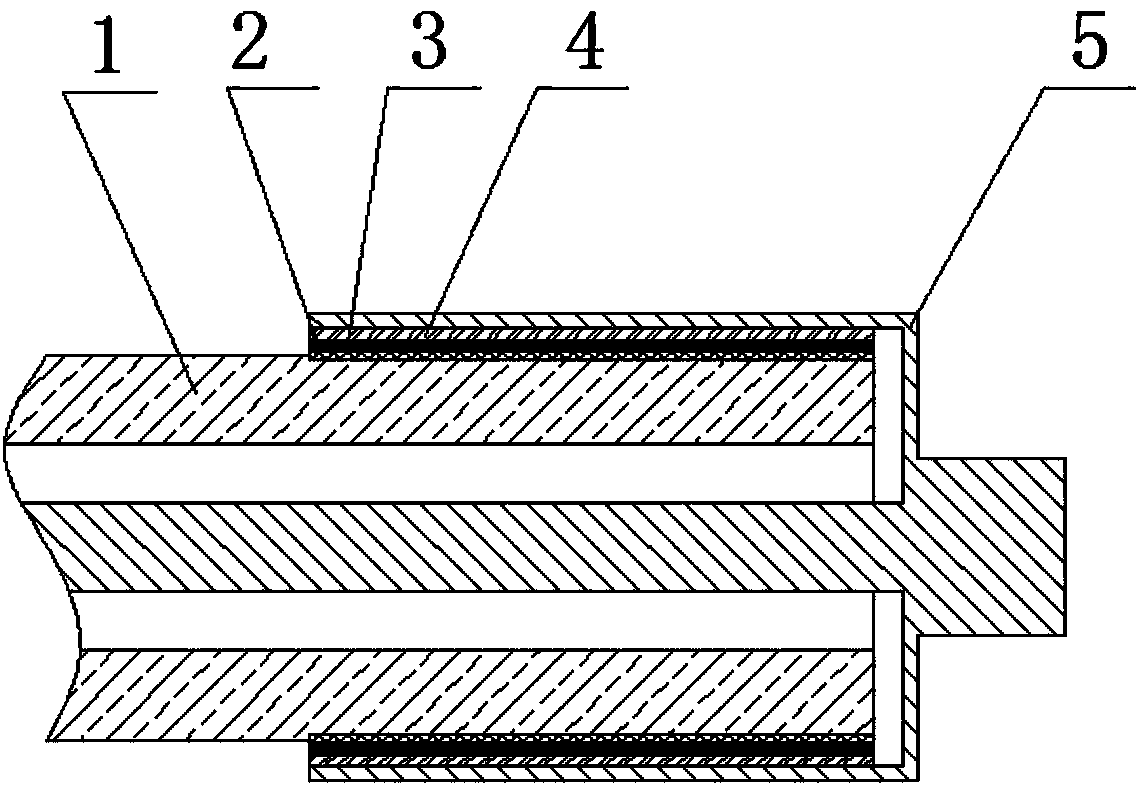

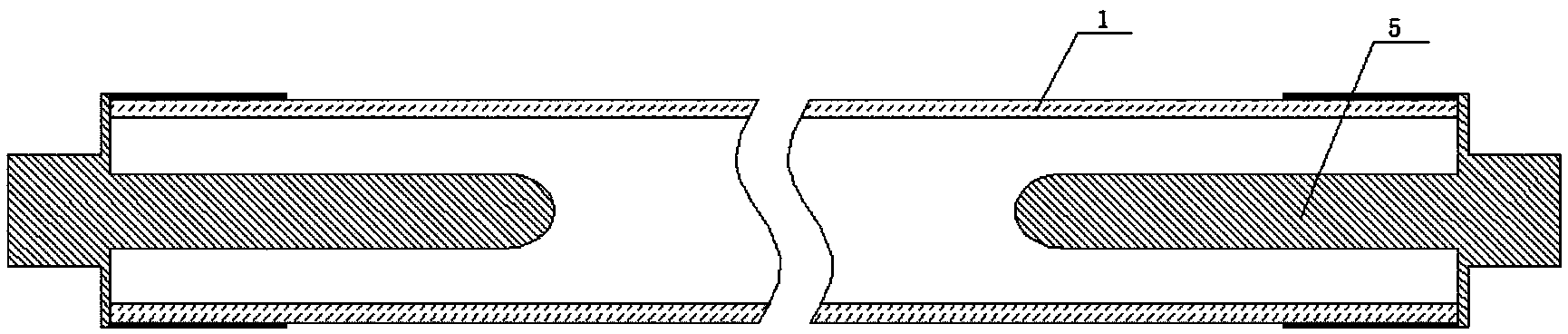

[0023] see first figure 1 , figure 1 It is a structural diagram of glass lamp tube and metal sealing, the sealing method of glass lamp tube and metal electrode of the present invention, comprises the following steps:

[0024] ① Clean the glass lamp tube 1, cover the part that does not need to be injected, place it in the ion implanter, and inject the active metal ion layer 2 on the surface of the glass lamp tube 1;

[0025] ②Plating a layer of metal film 3 outside the metal ion layer 2 of the glass lamp tube 1;

[0026] ③ The solder material 4 , the glass lamp tube 1 and the metal electrode assembly 5 are sealed together by a high-temperature brazing process.

[0027] Below is an embodiment, and concrete implementation method is as follows:

[0028] This embodiment is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com