Moving type hangar

A mobile and hangar technology, applied in the field of mobile hangars, can solve the problems of inability to change and change the hangar, high production cost, limited design space, etc., achieve simple and reliable manufacturing process, reduce the difficulty of erection, and reduce the effect of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

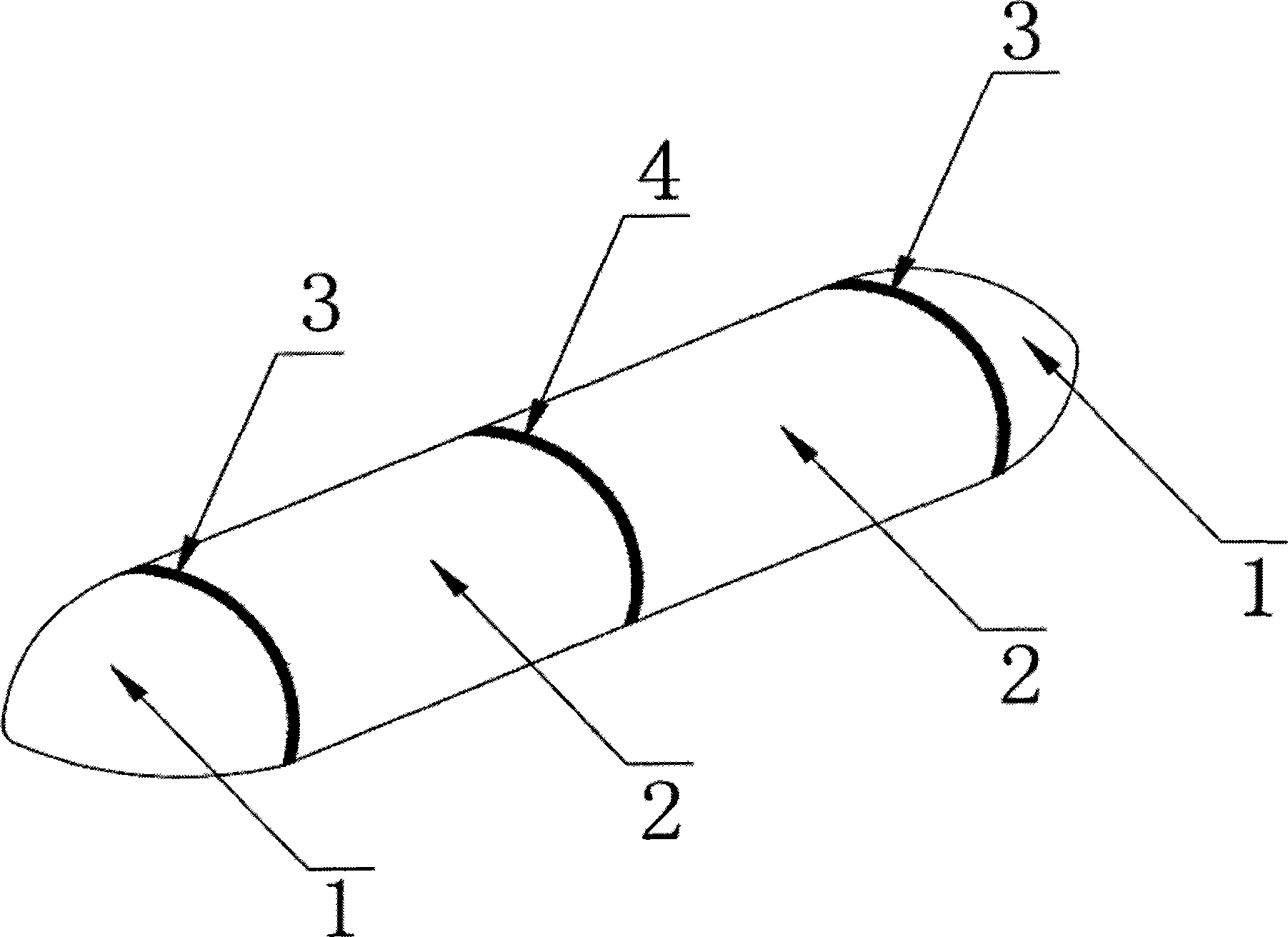

[0039] Such as figure 1 It is a schematic diagram of the main structure of the mobile hangar including two sets of intermediate bodies 2 , including end doors 1 and two sets of intermediate bodies 2 distributed at both ends of the hangar. Among them, 4 is the connection area where the two groups of intermediate bodies are connected to each other through the standard interfaces distributed at their ends, and 3 is the connection area where the end door is connected to the standard interface of the middle body through the special interface on the upper edge of the end door covering tarpaulin.

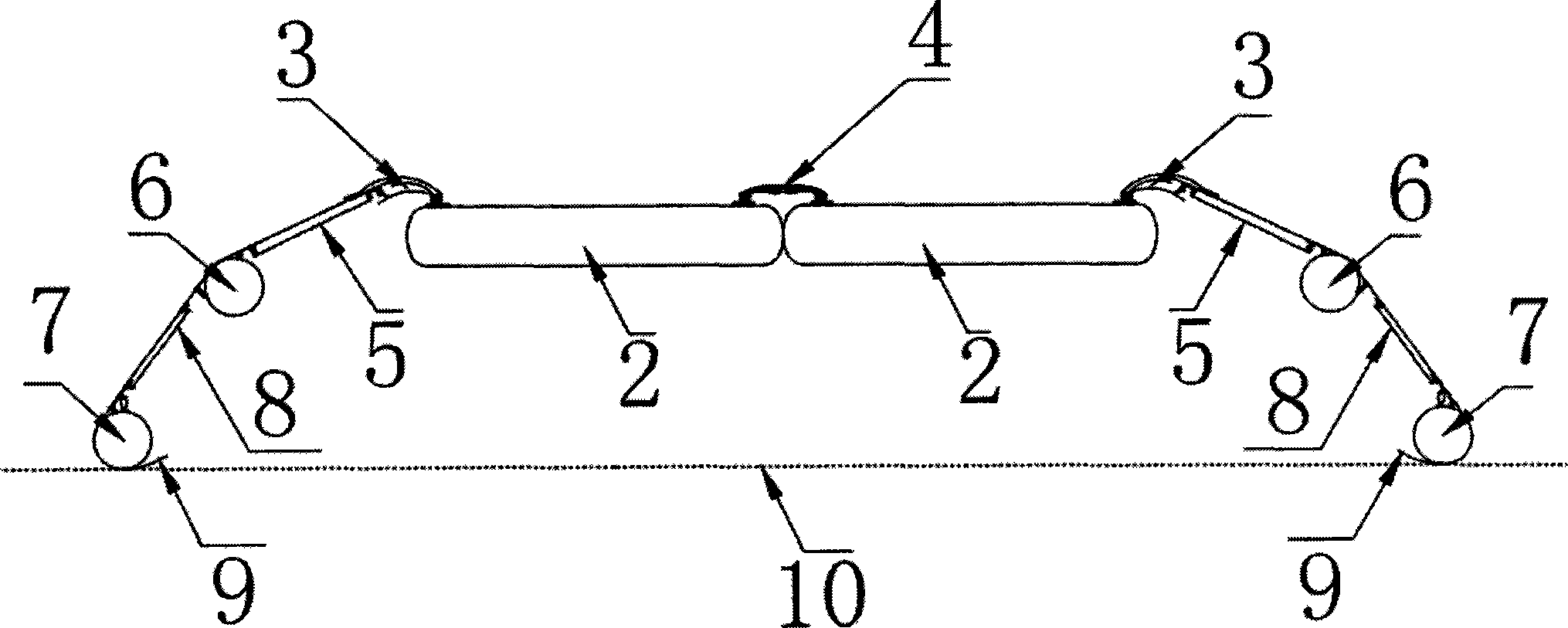

[0040] Such as figure 2 It is a schematic diagram of the longitudinal section of the mobile hangar including two sets of intermediate bodies. It includes 2 sets of middle bodies 2 and two sets of end doors, 4 is the connection area between the middle bodies, 3 is the connection area between the end doors and the middle body, and 5 is the limit of the opening device for the upper half of ...

Embodiment 2

[0047] In this embodiment, using the same manufacturing process and materials, the middle part of the hangar is designed as three sets of intermediate bodies connected to each other, and the hangar as a whole includes end doors distributed at two ends and three sets of intermediate bodies. Such as Figure 7 It is a schematic diagram of the longitudinal section of the hangar in this embodiment.

Embodiment 3

[0049] In this embodiment, using the same manufacturing process and materials, the middle part of the hangar is designed as four sets of intermediate bodies connected to each other, and the hangar as a whole includes end doors distributed at two ends and four sets of intermediate bodies. Such as Figure 8 It is a schematic diagram of the longitudinal section of the hangar in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com