Preparation method of POSS modified polysiloxane rubber composite material

A technology of polysiloxane and composite materials, which is applied in the field of functional polymer materials and nanocomposite materials, can solve the problems of POSS modified high-temperature vulcanized silicone rubber and other problems, so as to avoid a large amount of solvent recovery, broaden the application range, and avoid molecular weight The effect of the restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

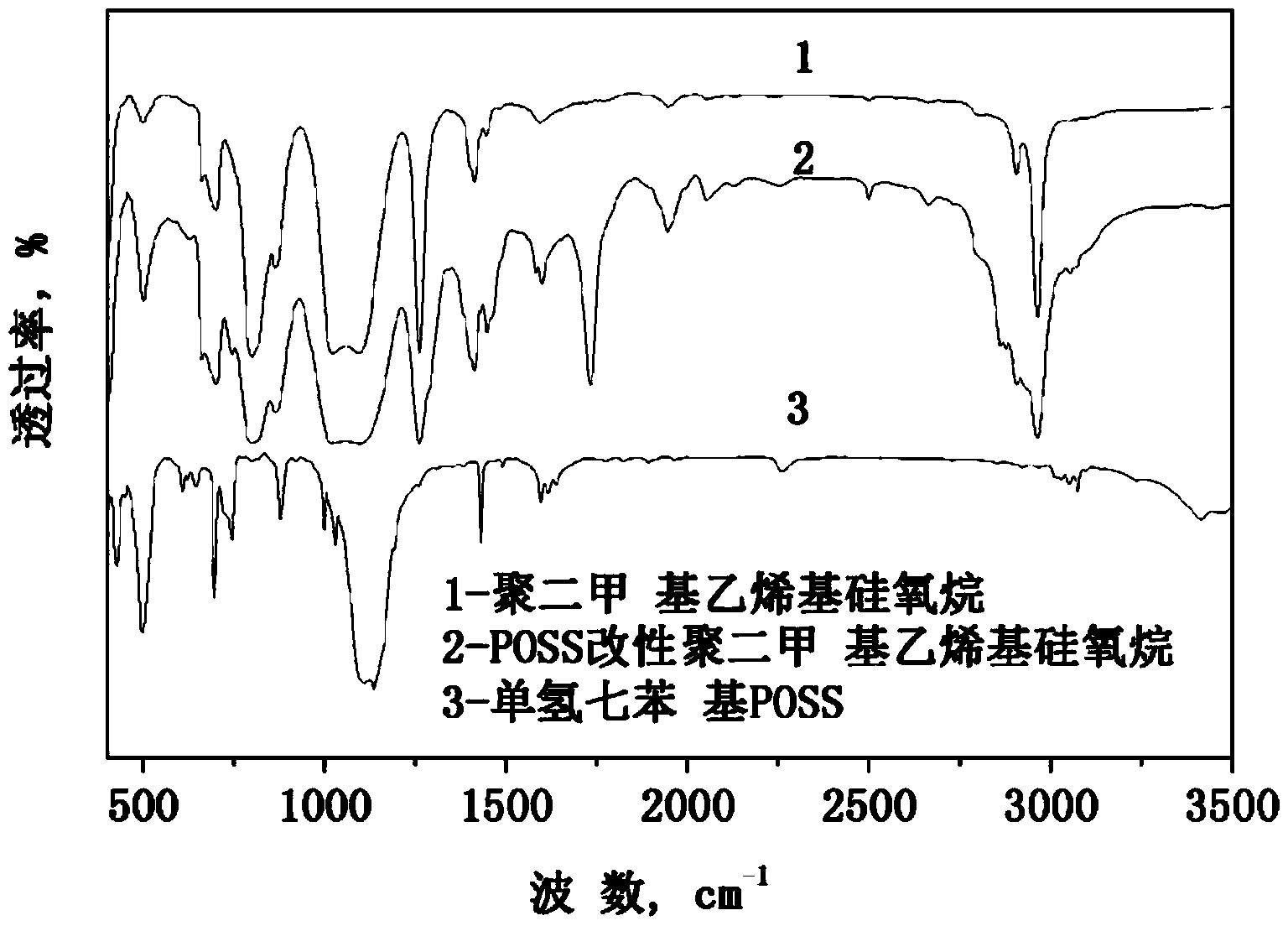

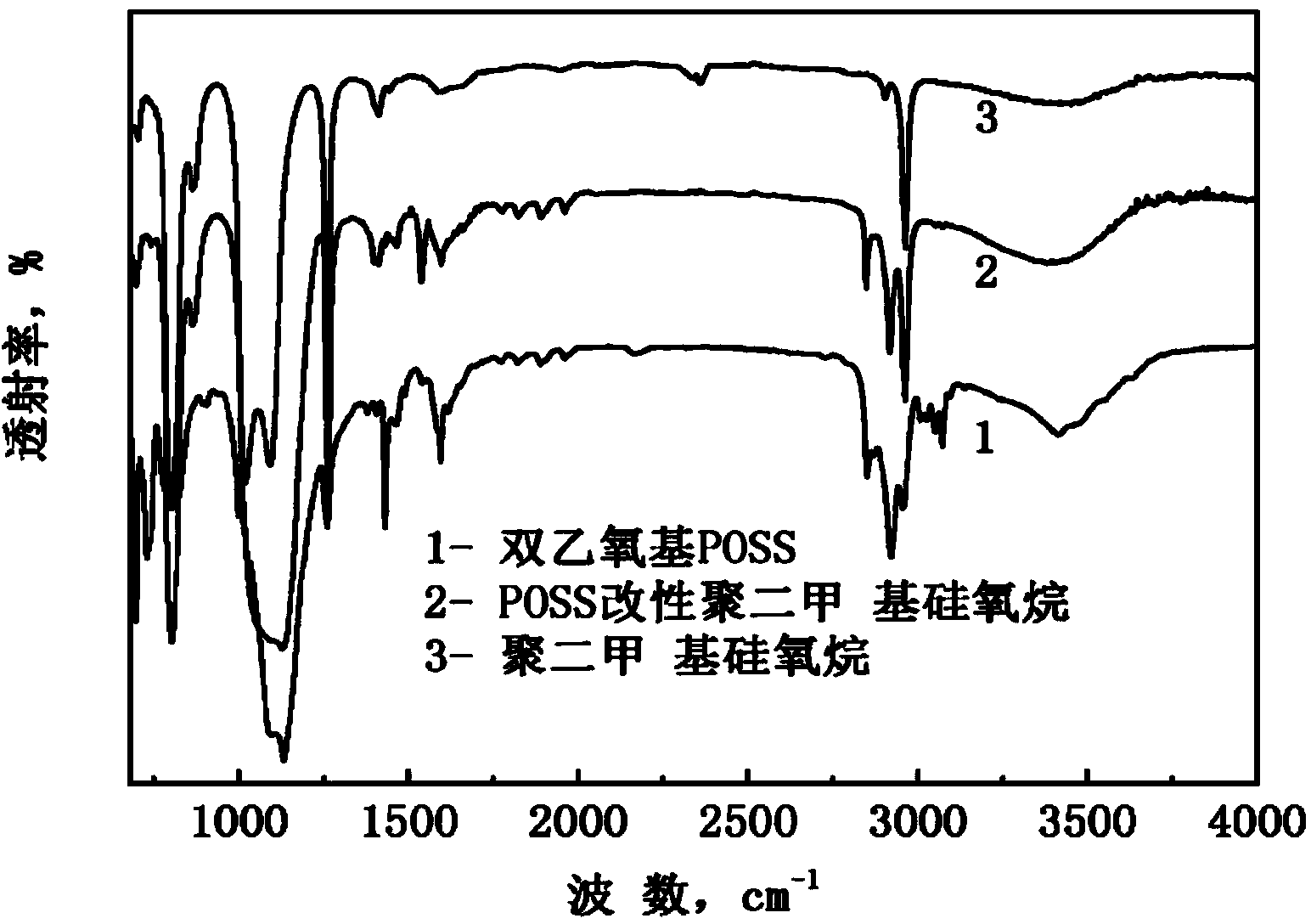

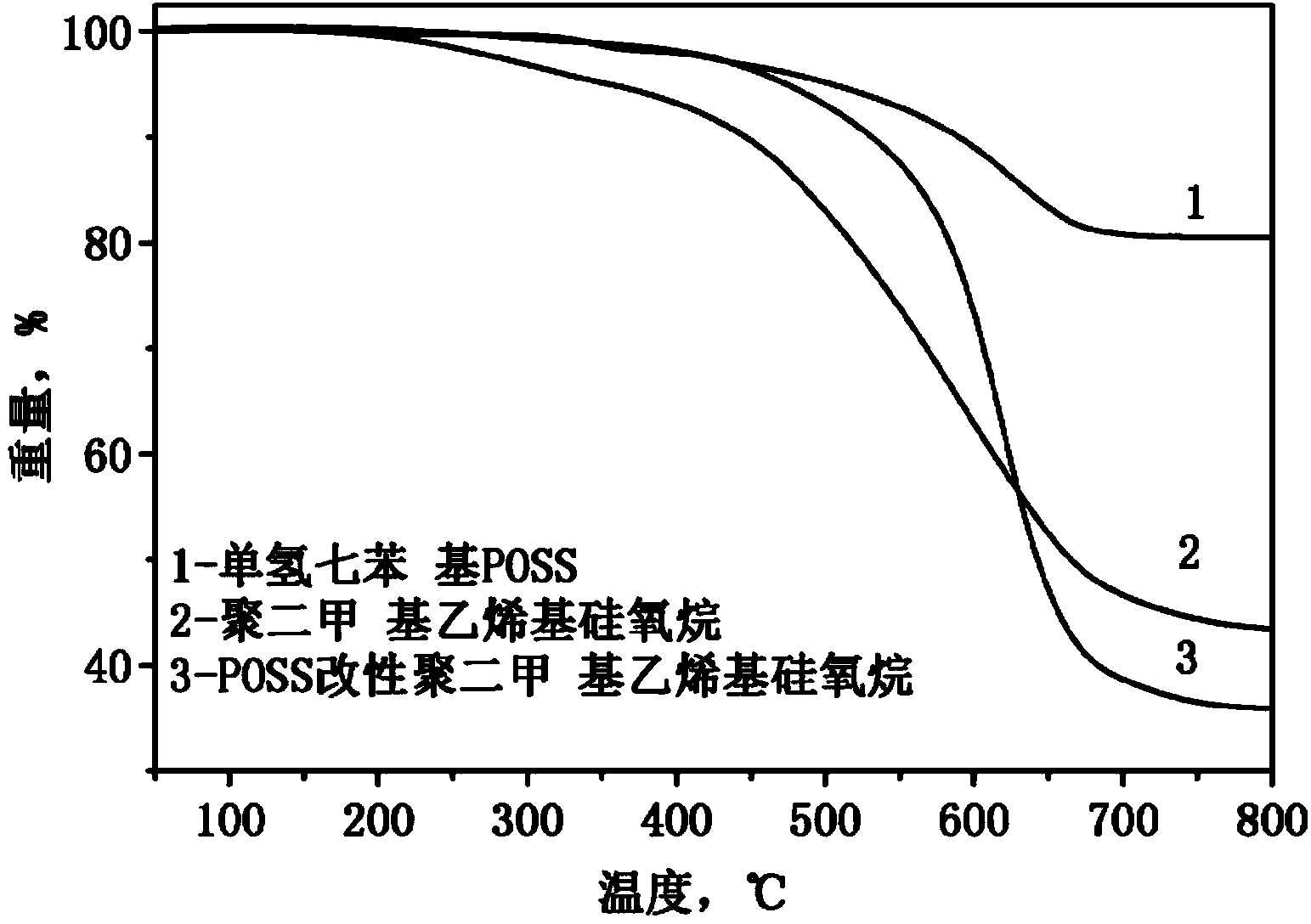

[0065] This embodiment is the preparation of POSS as the POSS modified polysiloxane rubber composite material of pendant chain

[0066] Add 5g of monohydroheptaphenyl POSS and 10g of vinyl silicone oil (vinyl content: 3wt%, molecular weight: 300,000) into a 100mL three-necked bottle equipped with a condenser. Under the protection of nitrogen, inject 60mL of toluene into the three-neck flask, start stirring, after heating to reflux temperature, add 8ul of Pt (dvs), and reflux for 72h until the reaction is complete. The solvent is removed from the obtained product to obtain a POSS-modified polysiloxane oligomer in which the POSS is located in the polysiloxane side chain.

[0067] Take 10g of the above-mentioned POSS modified polysiloxane oligomer and 50g of polydimethylvinylsiloxane body (molecular weight: 200,000, vinyl content: 0.15mol%), 6g hydrogen-containing silicone oil (hydrogen content: 0.5wt%) , molecular weight 3000g.mol -1 ) at 100-120°C for banburying, then mix the...

Embodiment 2

[0069] This embodiment is the preparation of POSS as the POSS modified polysiloxane rubber composite material of pendant chain

[0070] Add 10g of monohydroheptaphenyl POSS and 10g of vinyl silicone oil (vinyl content 5wt%, molecular weight 30,000) into a 250mL three-necked bottle equipped with a condenser. Under the protection of nitrogen, inject 180mL of toluene into the three-neck flask, start stirring, after heating to reflux temperature, add 18ul of Pt (dvs), and reflux for 48h until the reaction is complete. The solvent is removed from the obtained product to obtain a POSS-modified polysiloxane oligomer in which the POSS is located in the polysiloxane side chain.

[0071] Take 10g of the above-mentioned POSS modified polysiloxane oligomer and 50g of polydimethylvinylsiloxane body (molecular weight is 400,000, vinyl content is 0.18mol%), 2g hydrogen-containing silicone oil (hydrogen content is 0.5%, Molecular weight 3000g.mol -1 ) at 100-120°C for internal mixing, then ...

Embodiment 3

[0073] This embodiment is the preparation of POSS as the POSS modified polysiloxane rubber composite material of pendant chain

[0074] Mix 20g monohydroheptaphenyl POSS with 10g vinyl silicone oil (vinyl content 10wt%, molecular weight 3000g.mol -1 ) into a 500mL three-necked bottle equipped with a condenser. Under the protection of nitrogen, inject 300mL of toluene into the three-neck flask, start stirring, after heating to reflux temperature, add 40ul of Pt (dvs), and reflux for 72h until the reaction is complete. The solvent is removed from the obtained product to obtain a POSS-modified polysiloxane oligomer in which the POSS is located in the polysiloxane side chain.

[0075] Take 10g of the above-mentioned POSS modified polysiloxane oligomer and 50g of polydimethylvinylsiloxane body (molecular weight is 600,000, vinyl content is 0.20mol%), and 10g of white carbon black, 0.05g of double 5. Mix evenly on double rollers, and finally put the blended mixture into a mold coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com