In-situ preparation method of magnesium borate-magnesium oxide multiphase superconducting material with different superconducting phase contents

A superconducting material, in-situ preparation technology, applied in the manufacture/processing of superconductor devices, etc., can solve the unsolved problems of in-situ regulation of superconducting phase content, inability to obtain superconducting composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1. Preparation of substrate. Take a certain amount of B, Mg and B in a molar ratio of 2: 5: 1 2 o 3 After the powder is dried, it is weighed according to the predetermined molar ratio, fully ground, and pressed into a block by a tablet machine;

[0015] 2. The sealing of the base material. The specific steps are as follows: press the above-mentioned ground raw materials into blocks, put them into a ceramic crucible, cover them with a ceramic inner cover, and then sprinkle an appropriate amount of B 2 o 3 powder;

[0016] 3. Sintering of the base material. The above samples were sintered in a vacuum sintering furnace. During sintering, the following steps are followed: first, heat up to 420°C for half an hour (to form a protective barrier between the raw material and the outside world), then heat up to 620°C for 1 hour, and then heat up to 820°C for 2 hours. Finally, naturally cool to room temperature under vacuum atmosphere;

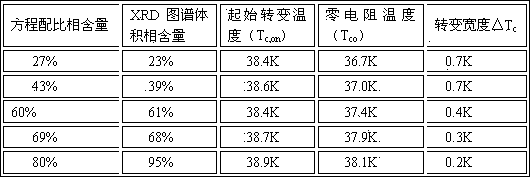

[0017] Through standard four-lead r...

Embodiment 2

[0019] 1. Preparation of substrate. Take a certain amount of powder B, Mg and B at a molar ratio of 6:7:1 2 o 3 After drying, it is weighed according to the predetermined molar ratio, fully ground, and pressed into a block by a tablet press;

[0020] 2. The sealing of the base material. The specific steps are as follows: press the above-mentioned ground raw materials into blocks, put them into a ceramic crucible, cover them with a ceramic inner cover, and then sprinkle an appropriate amount of B 2 o 3 powder;

[0021] 3. Sintering of the base material. The above samples were sintered in a vacuum sintering furnace. During sintering, the following steps are followed: first, heat up to 450°C for half an hour (to form a protective barrier between the raw material and the outside world), then heat up to 650°C for 1 hour, and then heat up to 850°C for 2 hours. Finally, naturally cool to room temperature under vacuum atmosphere;

[0022] Through standard four-lead resistance ...

Embodiment 3

[0024] 1. Preparation of substrate. Take a certain amount of B, Mg and B at a molar ratio of 10:9:1 2 o 3 After the powder is dried, it is weighed according to the predetermined molar ratio, fully ground, and pressed into a block by a tablet machine;

[0025] 2. The sealing of the base material. The specific steps are as follows: press the above-mentioned ground raw materials into blocks, put them into a ceramic crucible, cover them with a ceramic inner cover, and then sprinkle an appropriate amount of B 2 o 3 powder;

[0026] 3. Sintering of the base material. The above samples were sintered in a vacuum sintering furnace. During sintering, the following steps are followed: first, heat up to 420°C for half an hour (to form a protective barrier between the raw material and the outside world), then heat up to 620°C for 1 hour, and then heat up to 820°C for 2 hours. Finally, naturally cool to room temperature under vacuum atmosphere;

[0027] Through standard four-lead re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com