Bullet-proof security tire and manufacturing method of self-sealing polymer material used in bullet-proof security tire

A safety tire and polymer technology, applied in tire parts, reinforcement layers of pneumatic tires, vehicle parts, etc., can solve the problems of low temperature resistance, edge stripping, self-sealing layer shedding, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

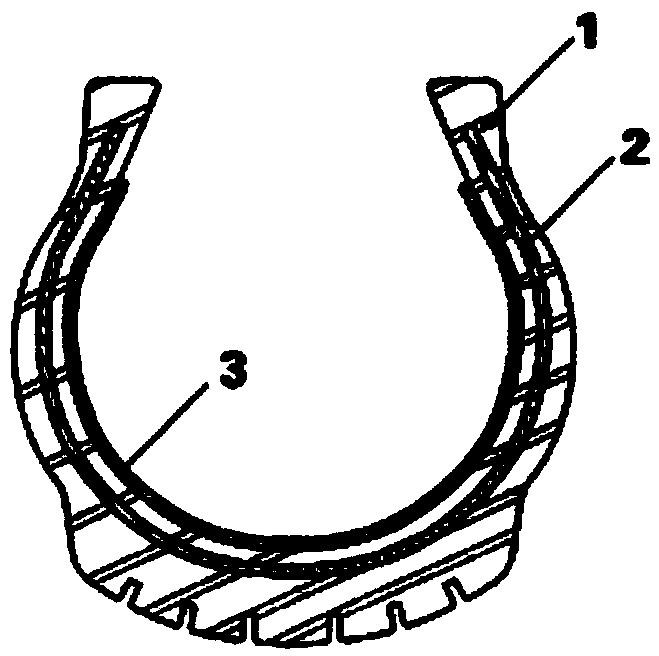

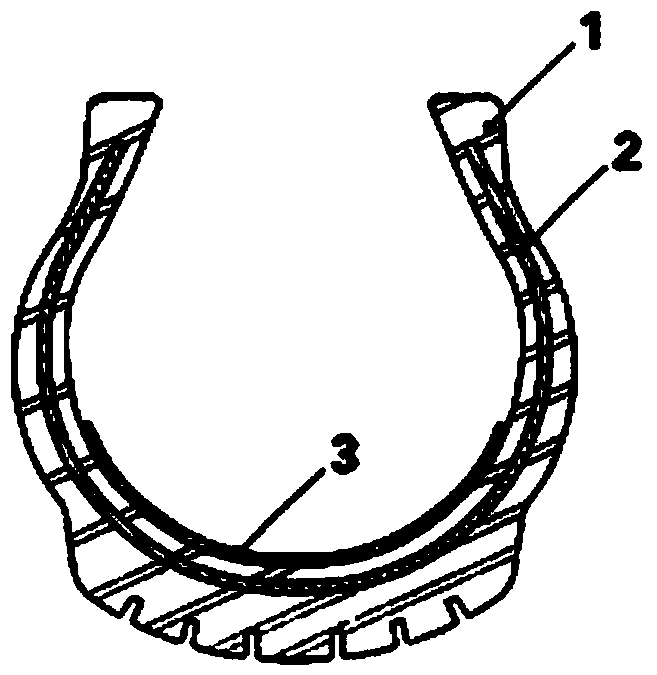

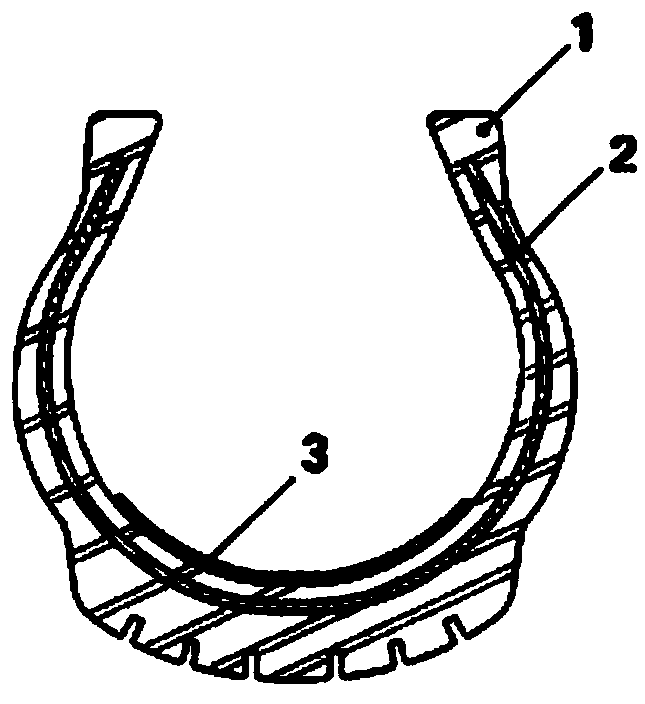

Image

Examples

Embodiment 1

[0034] 100 parts by mass of styrene thermoplastic elastomer, 130 parts by mass of tackifier, 80 parts by mass of softener, and 5 parts by mass of auxiliary agent; the specific components and their parts by mass are shown in Table 1.

[0035] Table 1

[0036] serial number

Embodiment 2

[0038] 100 parts by mass of styrene thermoplastic elastomer, 100 parts by mass of tackifier, 80 parts by mass of softener, and 5 parts by mass of auxiliary agent; the specific components and their parts by mass are shown in Table 2.

[0039] Table 2

[0040]

Embodiment 3

[0042] 100 parts by mass of styrene thermoplastic elastomer, 100 parts by mass of tackifier, 80 parts by mass of softener, and 5 parts by mass of auxiliary agent; the specific components and their parts by mass are shown in Table 3.

[0043] table 3

[0044]

[0045] In the above-mentioned embodiment, in addition to producing the relevant polymer self-sealing material, the steps of the manufacturing method of the bulletproof safety tire are as follows:

[0046] (1) Use car tire cleaning agent and defect equipment to clean the inner wall surface of car tires at medium temperature, so that the inner wall surface of car tires can meet the requirements of adhesion.

[0047] (2) Use hot air heating equipment to heat the surface of the inner wall of the car tire, so that the temperature of the inner wall surface reaches above 60 degrees Celsius, so that the surface of the inner wall can be stretched evenly, and reduce the contact between the inner wall surface of the car tire and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com