Raw coal washing system

A raw coal and coarse coal technology, applied in solid separation, wet separation, grain processing, etc., can solve the problems of difficult residue cleaning, low combustion efficiency, and large coal transportation volume, and reduce labor costs and transportation equipment costs , Reduce the waste of transportation capacity and improve the efficiency of coal combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

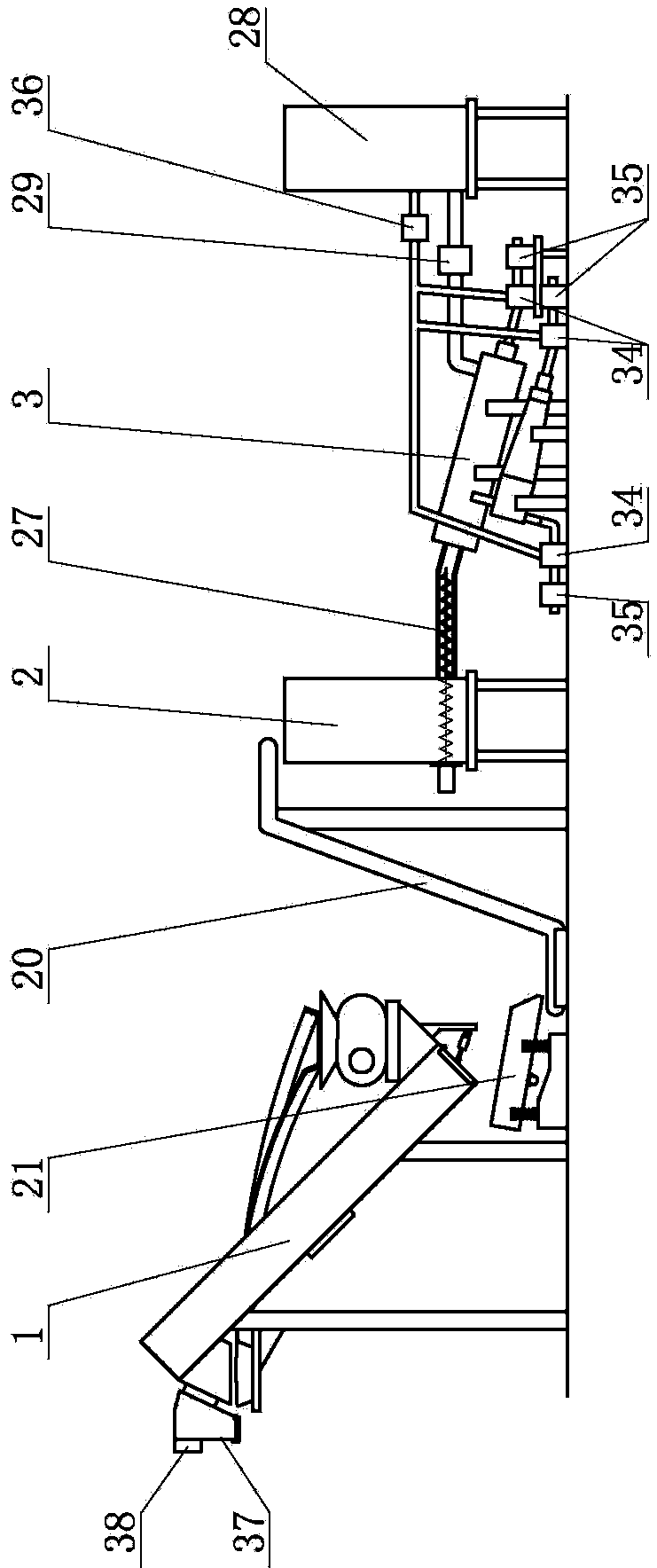

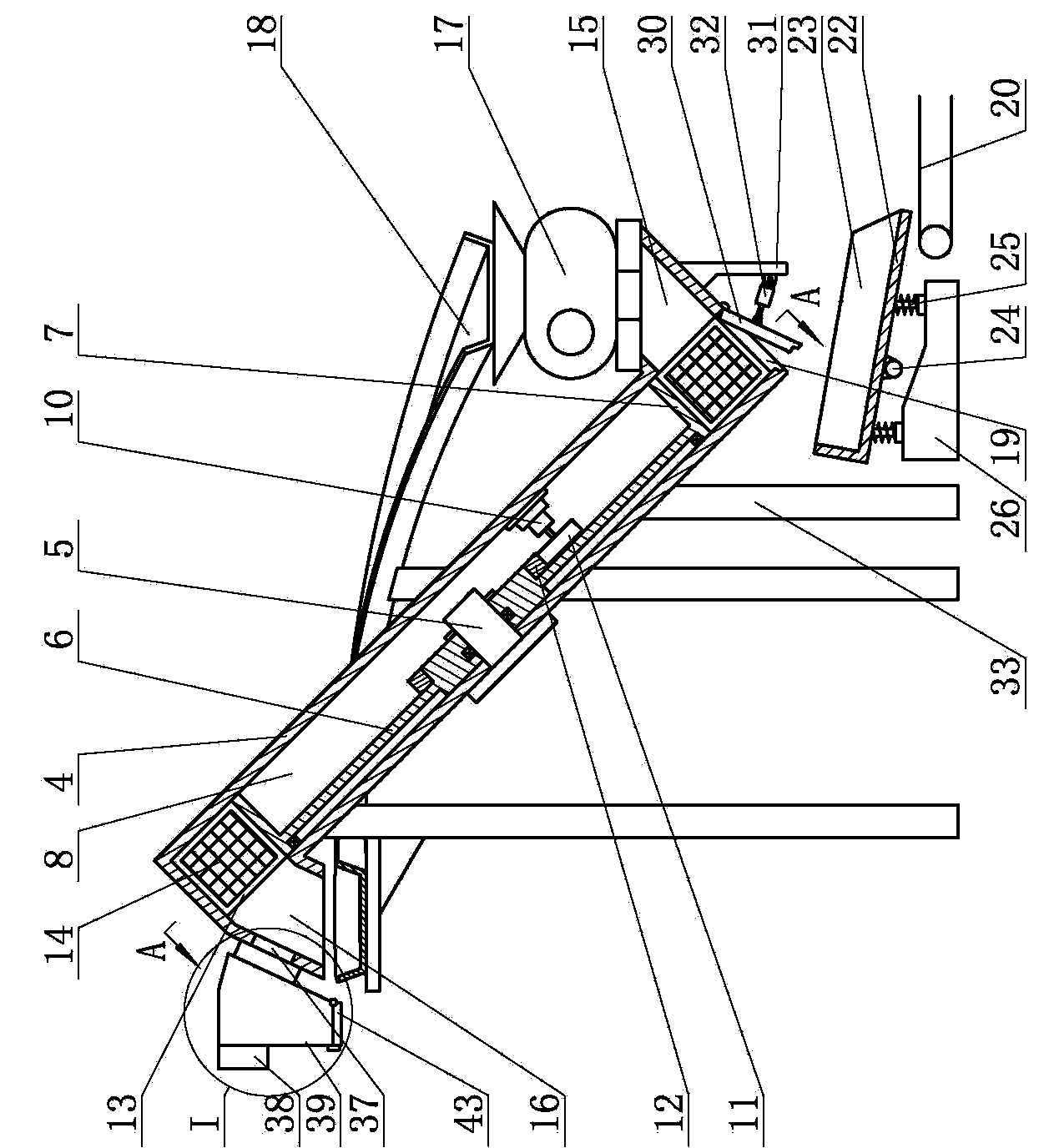

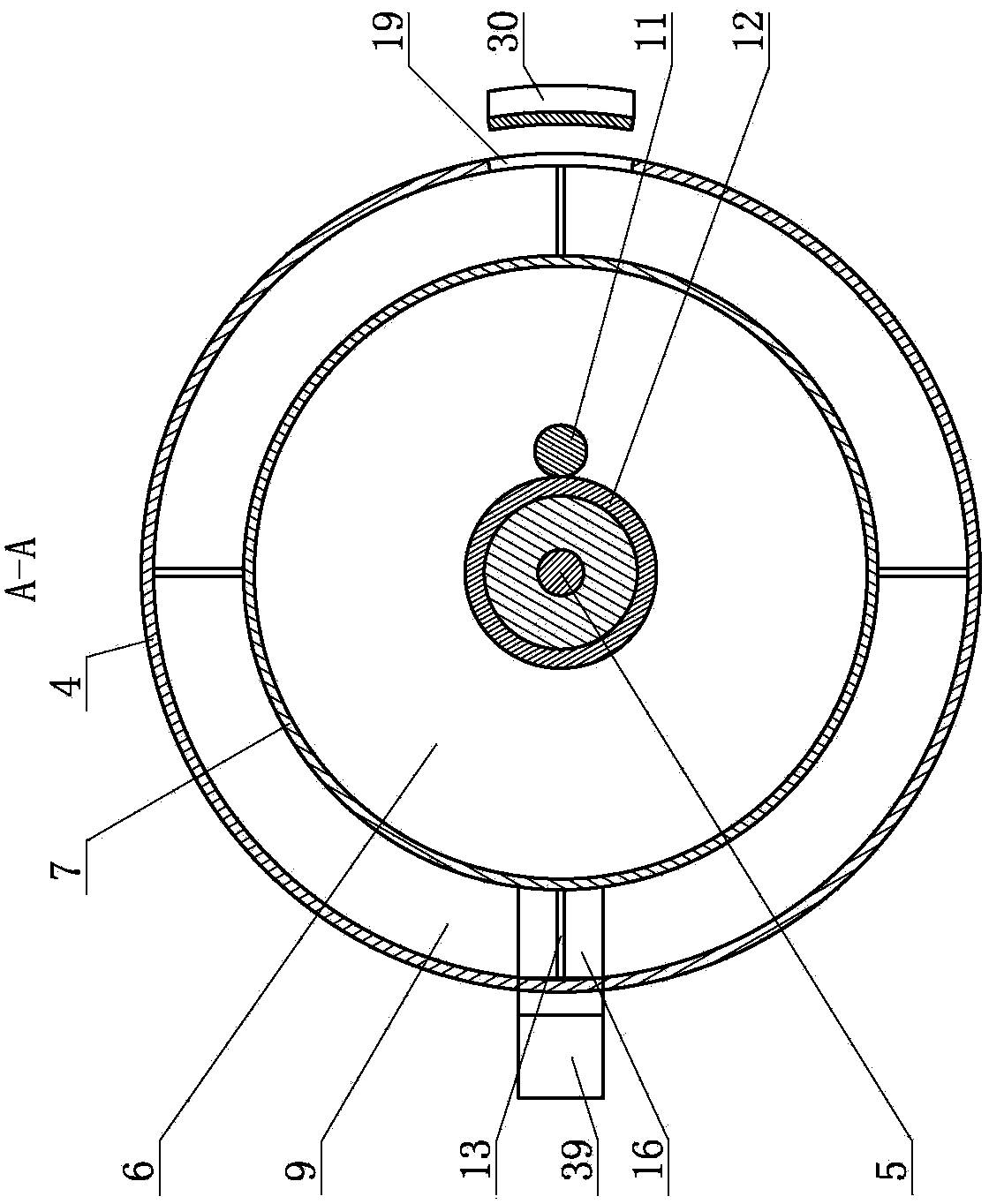

[0011] A raw coal washing system includes a circulating coal crushing device 1, the circulating coal crushing device 1 includes a separator and a raw coal crusher 17, the separator has a hollow disk-shaped shell 4, and the shell 4 includes two parallel The circular side walls of the two circular side walls are connected by an annular side wall. The two circular side walls of the housing 4 are inclined 30°-60° relative to the horizontal plane. The inner axis of the housing 4 is installed A turntable 6 is installed on the axis 5 and the central axis 5, and the turntable 6 can rotate around the central axis 5. The outer edge of the turntable 6 is provided with an isolation ring 7, and the isolation ring 7 separates the housing 4 into a disc-shaped cavity 8 in the middle and an annular ring around the periphery. Cavity 9, drive motor 10 is set in disc-shaped cavity 8, drive motor 10 is fixedly installed on the inner wall of housing 4, drive gear 11 is installed on the output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com