C-SiC catalyst, its preparation and its application thereof

A catalyst, c-sic technology, applied in hydrogen halide addition preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as non-metallic catalysts that have not been reported in the application, to avoid pollution problems, cheap raw materials Easy to obtain, high catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Put 0.80g of SiC particles (40-60 mesh) into a tube furnace, and program the temperature up to 800°C under an Ar gas atmosphere, with a heating rate of 5°C / min, and then pass the CCl4 liquid through Ar gas bubbling. The flow rate of Ar was 50ml / min, and the inflow time was 2h, and then switched to pure Ar atmosphere to lower the temperature. The obtained sample was named C-SiC.

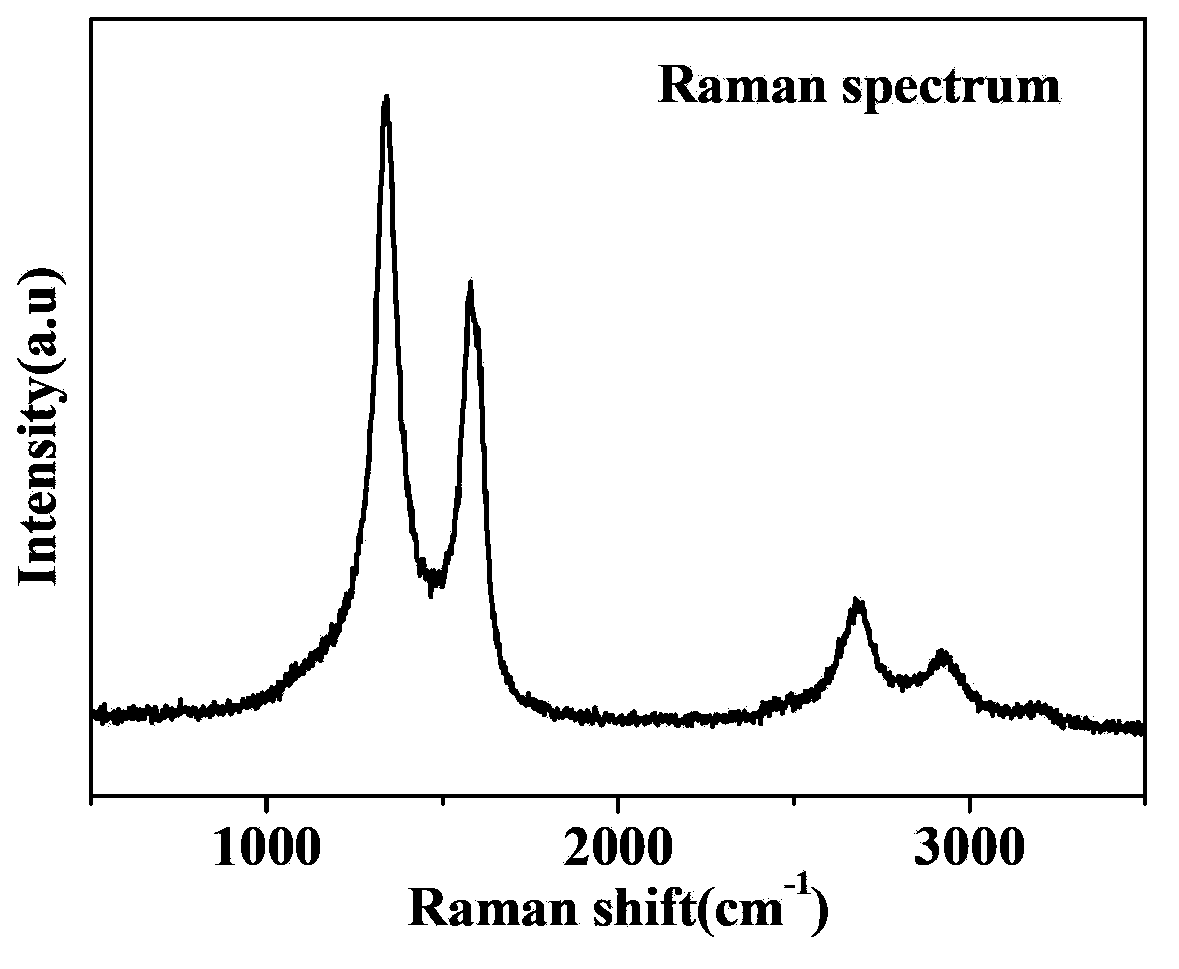

[0034] figure 1 In order to obtain the Raman characterization of the sample, the characteristic peaks of the carbon layer are shown in the Raman diagram: D peak and G peak, which prove the formation of the carbon layer.

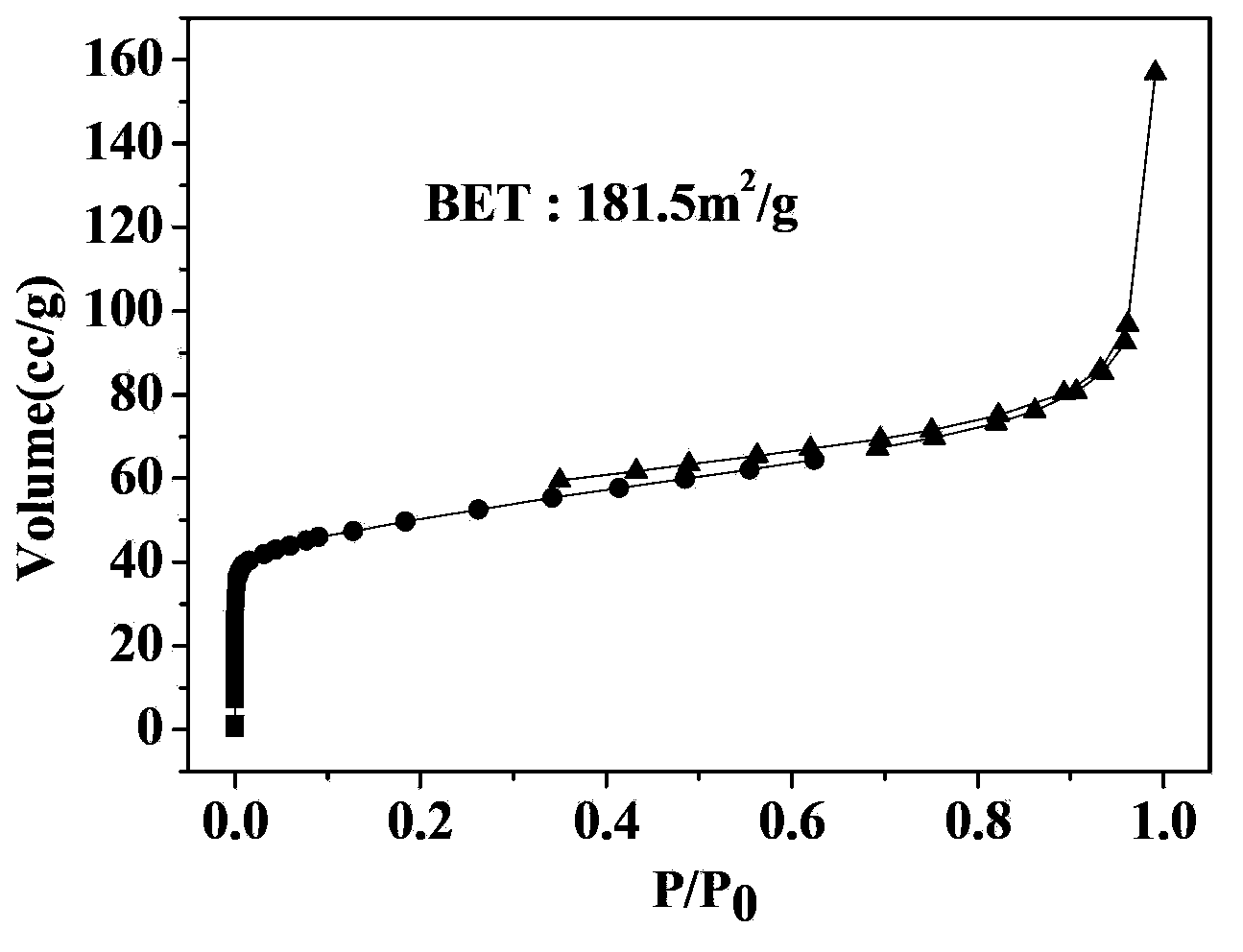

[0035] figure 2 It is the adsorption-desorption curve of the prepared C-SiC sample, and its specific surface area is 181m 2 / g, proving that the generated carbon layer is a porous carbon layer.

Embodiment 2

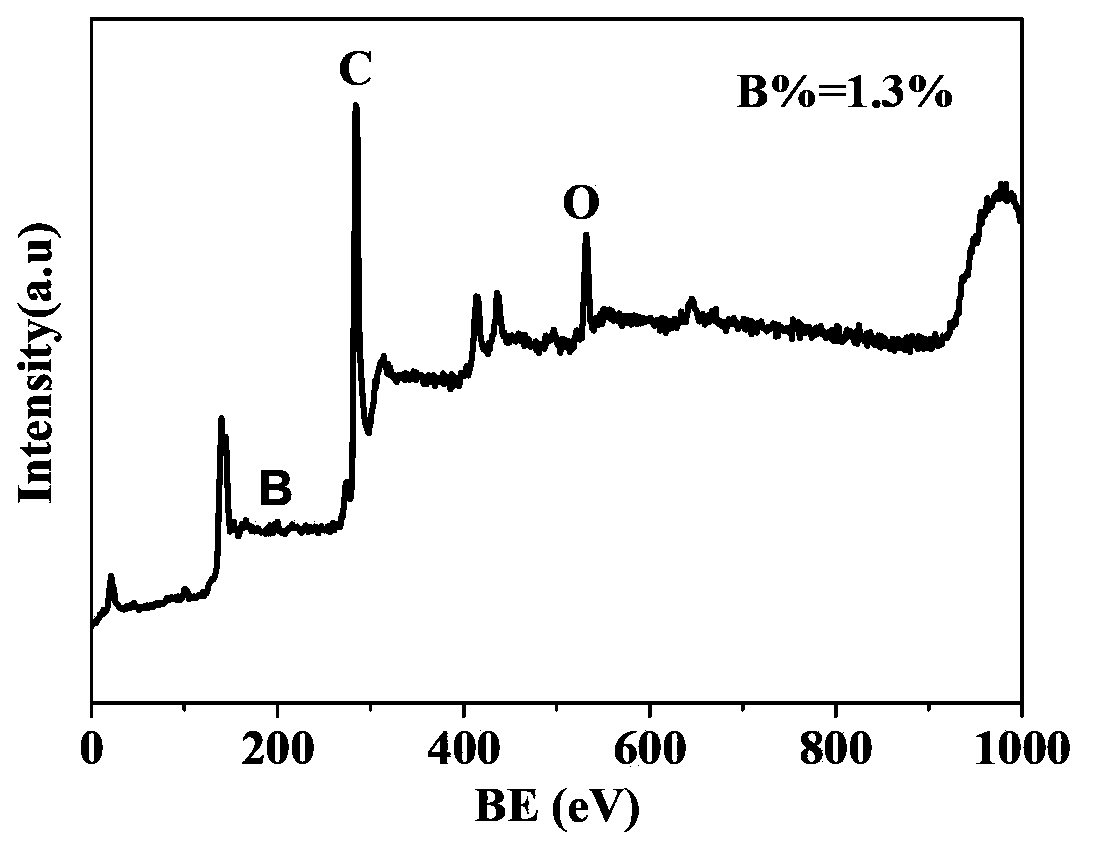

[0037] Preparation of boron-doped B-C-SiC material: mix 1.2g C-SiC with B 2 o 3 mechanical mixing, B 2 o 3 The mass ratio to C-SiC is 1:3, placed in a high-temperature furnace, under an Ar gas atmosphere, the temperature is raised to 1100°C at a rate of 5°C / min, kept for 6h, and taken out with 30wt% NaOH after cooling down The solution was fully washed, suction filtered, and dried at 120°C, and the obtained sample was named B-C-SiC. image 3 It is the XPS spectrum of B-C-SiC, which proves that B atoms are successfully doped into the carbon layer skeleton, and the mass ratio of B atoms to the carbon layer is 1.3%.

Embodiment 3

[0039] Preparation of nitrogen-doped N-C-SiC material: 0.80 g of SiC particles (40-60 mesh) were placed in a tube furnace, and the temperature was programmed to rise to 800 ° C under an Ar gas atmosphere at a heating rate of 5 ° C / min, and then CCl 4 The liquid is fed in by bubbling Ar gas, the flow rate of Ar is 50ml / min, while CCl4 is fed in, NH3 is fed in from another channel at the same time, NH 3 The flow rate was 9ml / min, and the flow was continued for 2h, then switched to a pure He atmosphere to lower the temperature, and the obtained sample was named N-C-SiC. Figure 4 is the XPS spectrum of N-C-SiC, by Figure 4 It can be seen that N atoms are successfully doped like the carbon layer skeleton, and the mass ratio of N atoms to the carbon layer is 9.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com