Method and equipment for pressure-reduction freshness-retaining storage of wild edible mushrooms

A technology of wild edible fungi and equipment, applied in the direction of preservation of fruits/vegetables through freezing/refrigeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

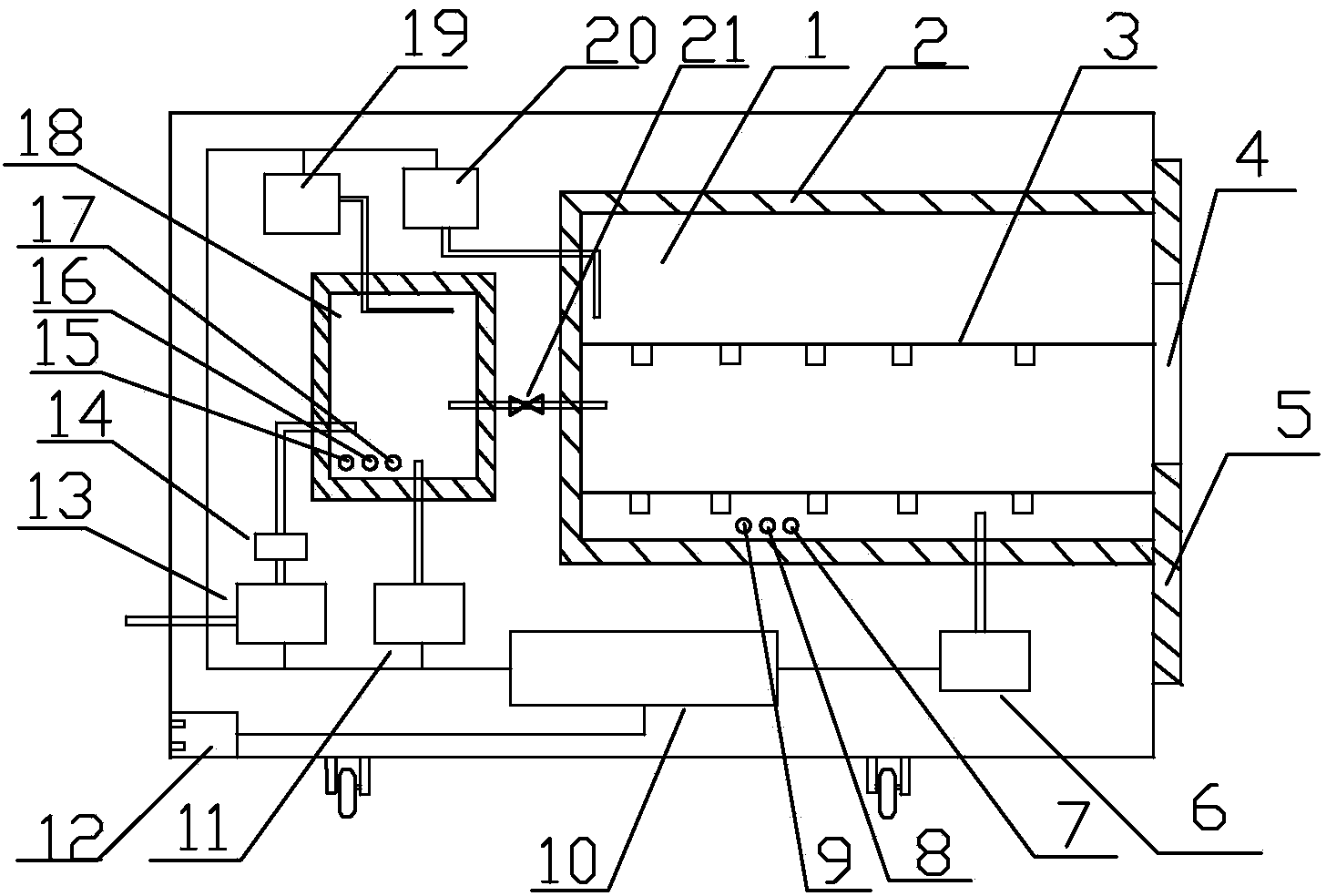

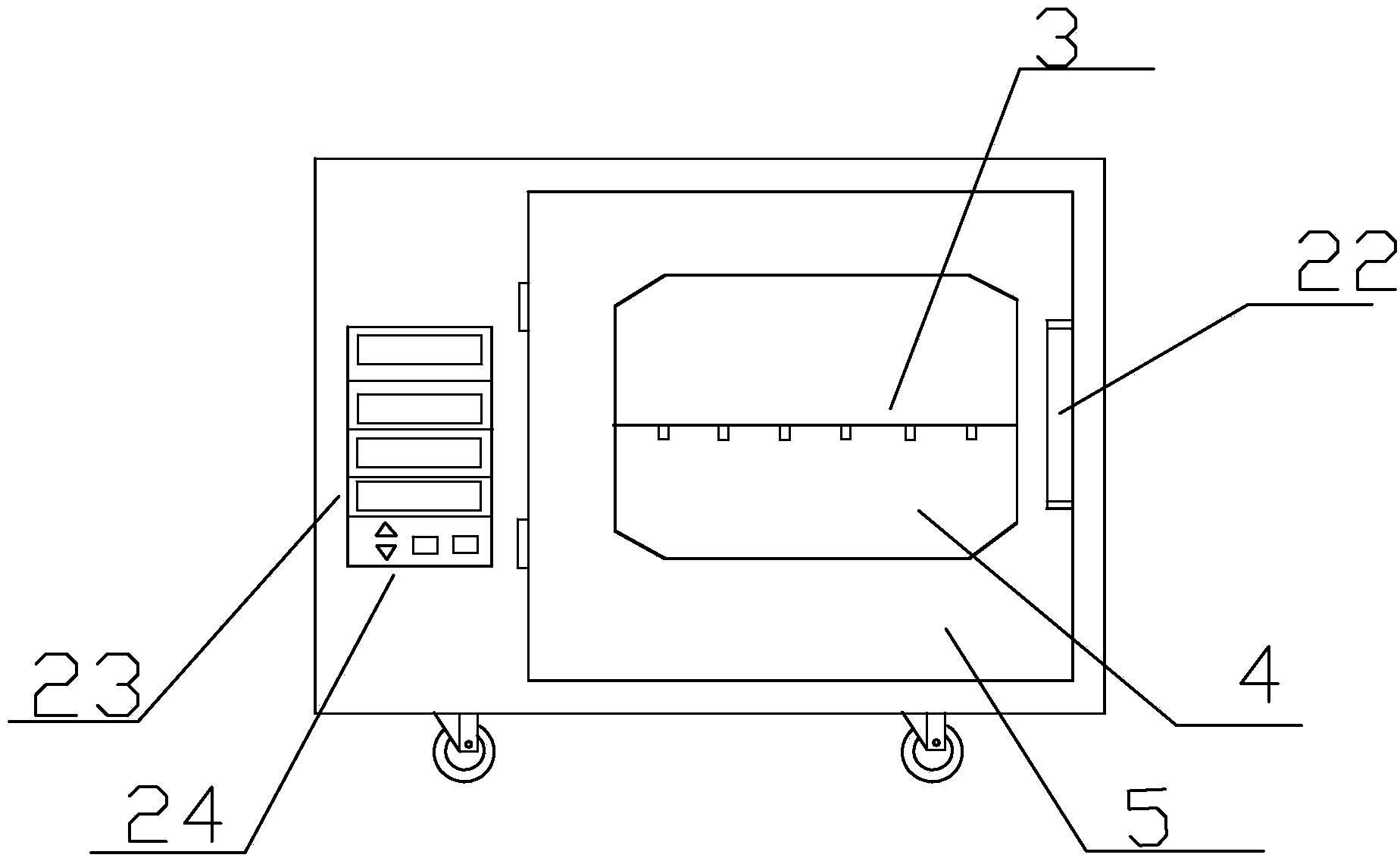

[0019] Embodiment 1: Decompression storage and fresh-keeping equipment

[0020] see figure 1 and figure 2 When a kind of edible mushroom decompression storage equipment is used, the temperature, humidity and vacuum degree in the gas pretreatment chamber are first set on the setting plate (24), and the device is started to make the vacuum pump (11) and the refrigeration device (19) and When the air humidifier (13) pre-treats the incoming air to reach the pressure, temperature, and humidity required for storage, set the temperature, humidity, and vacuum degree in the storage room, and open the vent valve (21) to make the pre-treated stable gas into the storage room (1), while the storage room is connected to the vacuum pump (6) and the refrigeration device (20), the vacuum pump (6) continuously pumps air to reduce the pressure of the storage room, and the refrigeration device (20) refrigerates the storage room, so that The device is always in the constant low-pressure and ...

Embodiment 2

[0021] Embodiment 2: the decompression precooling fresh-keeping method of matsutake

[0022] After the harvested fresh matsutake is transported to the base through the cold chain, it is immediately put into the vacuum storage room, and the temperature in the storage room is set on the setting board to be 2±0.5°C, the humidity is 90%, and the pressure is 1.5kPa, and then the device is started , During the pre-cooling period, the quality of matsutake can be observed through the observation window. After 24 hours, take it out of the decompression refrigeration equipment and put it in a low-temperature refrigerator (temperature is 2±0.5°C, humidity is about 90%). After 15 days, the smell of matsutake is strong, and the original color of matsutake is retained. After cutting, the internal color is whiter. It is still edible, indicating that the decompression precooling method and equipment provided by the present invention can play the effect of prolonging the fresh-keeping period...

Embodiment 3

[0023] Embodiment 3: the decompression storage and fresh-keeping method of matsutake

[0024] After the harvested fresh matsutake is transported to the base through the cold chain, it is immediately placed in a vacuum storage room. The temperature in the storage room is set at 2±0.5°C, the humidity is about 90%, and the pressure is 1.5kPa. During storage, you can pass through the observation window (3) Observe the quality of matsutake. Take it out after 17 days in the decompression storage equipment, and put it into the freezer for 8 days. Although the smell of matsutake is a bit light, it still retains the original color of matsutake. The fresh-keeping method and equipment of pressure storage can play a role in prolonging the fresh-keeping period of matsutake.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com