Squirrel-cage induction motor

An induction motor and cage-type technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of rising rotor manufacturing costs, high melting point of copper, and inability to use die-casting aluminum machines, etc., and achieve the goal of suppressing the rise of manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

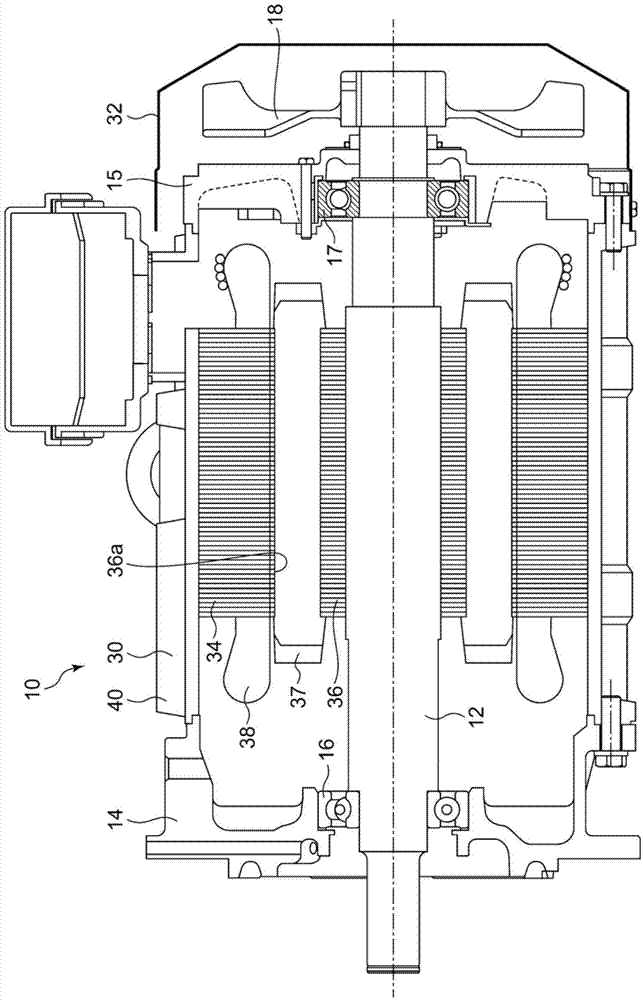

[0015] figure 1 It is a cross-sectional view when the cage-type induction motor 10 is cut along a vertical plane including the central axis.

[0016] The stator 34 is formed by laminating a plurality of thin-plate-shaped (for example, thickness 0.5 mm) electromagnetic steel sheets that are punched out in the same shape. The stator 34 is fitted to the inner periphery of the frame 30 by, for example, shrink fitting. A coil 38 of copper wire is wound on a plurality of slots formed in the stator 34 .

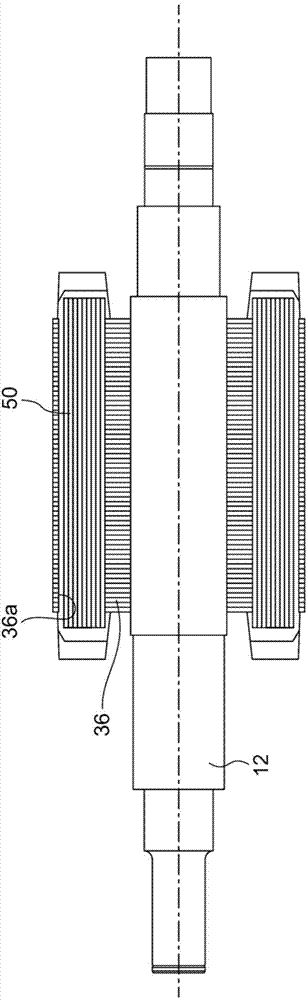

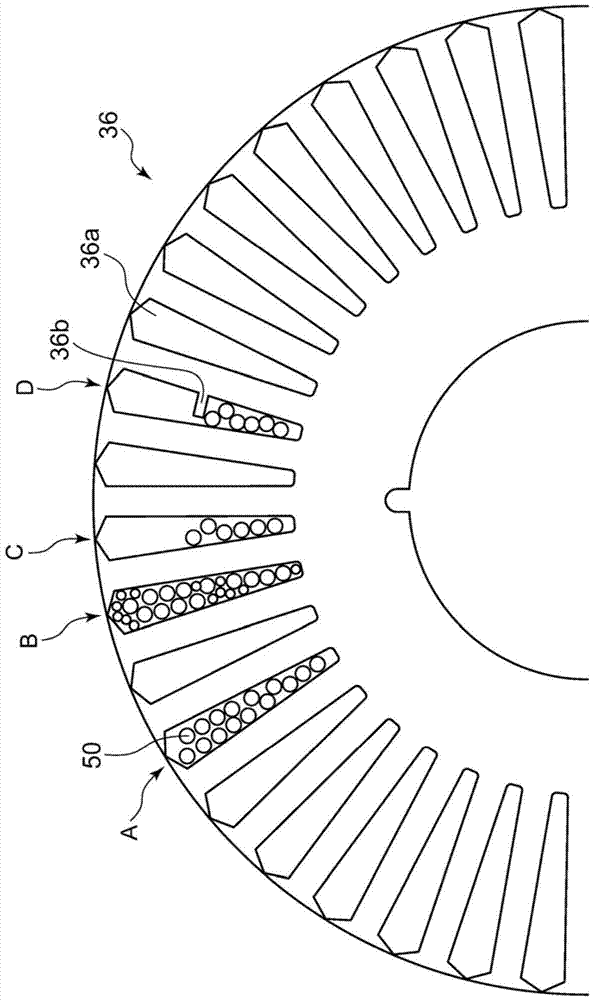

[0017] The rotor 36 is similarly formed by laminating a plurality of thin-plate-shaped electrical steel sheets that were punched out in the same circular shape. A circular hole for inserting the rotating shaft 12 toward the center is formed on the rotor 36, and a plurality of slots 36a of the same shape extending radially are formed at equal intervals on its outer peripheral side (refer to image 3 ). The circular bore of the rotor 36 is secured to the motor shaft 12 by an inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com