A method and device for light-sheet illumination microscopy based on difference

A light-sheet and differential technology, which is applied in the microscopic field of light-sheet illumination, to achieve the effect of ensuring imaging depth, realizing super-resolution imaging, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

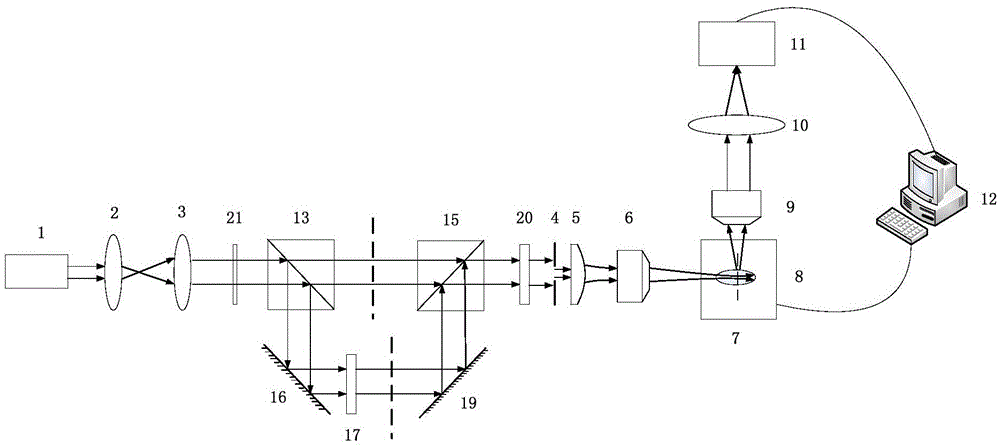

[0035] Such as figure 2 As shown, a shutter-controlled light sheet illumination microdevice for fluorescent samples, including a laser 1, a first lens 2, a second lens 3, a first polarizing beam splitter 13, a first shutter 14, a second Two polarizing beam splitters 15, a quarter wave plate 20, a slit 4, a cylindrical mirror 5, a first objective lens 6, a first reflector 16, a phase plate 17, a second shutter 18, a second reflector 19, a sample 7. Nano translation stage 8, second objective lens 9, third lens 10, detector 11 and computer 12.

[0036] use figure 2 The shown setup implements a differential-based light-sheet illumination microscopy method for samples, and the procedure is as follows:

[0037] (1) The laser 1 emits illumination light, which is expanded by the first lens 2 and the second lens 3;

[0038] (2) The expanded illumination light is divided into two orthogonal linearly polarized beams by the first polarizing beam splitter 13, in which the vertically p...

Embodiment 2

[0044] Such as image 3 As shown, a differential-based light sheet illumination microdevice controlled by a liquid crystal light valve for fluorescent samples includes a laser 1, a first lens 2, a second lens 3, a liquid crystal light valve 21, and a first polarizing beam splitter 13 , second polarizing beam splitter 15, quarter wave plate 20, slit 4, cylindrical mirror 5, first objective lens 6, first mirror 16, phase plate 17, second mirror 19, sample 7, nano Translation stage 8, second objective lens 9, third lens 10, detector 11 and computer 12.

[0045] use image 3 The shown setup implements a differential-based light-sheet illumination microscopy method for samples, and the procedure is as follows:

[0046] (1) The laser 1 emits illumination light, which is expanded by the first lens 2 and the second lens 3;

[0047] (2) First, use the liquid crystal light valve 21 to convert the beam-expanded illumination light into parallel polarized light (p light), and the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com