Heat dissipating system of LED street lamp

A technology of LED street lamps and heat dissipation systems, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, lighting devices, etc., and can solve the problem of complex waterproof and moisture-proof structures of LED chips, which are not suitable for power heat dissipation, rainproof, and flow heat dissipation Poor performance and other problems, to achieve the effect of good heat dissipation, good heat dissipation effect, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

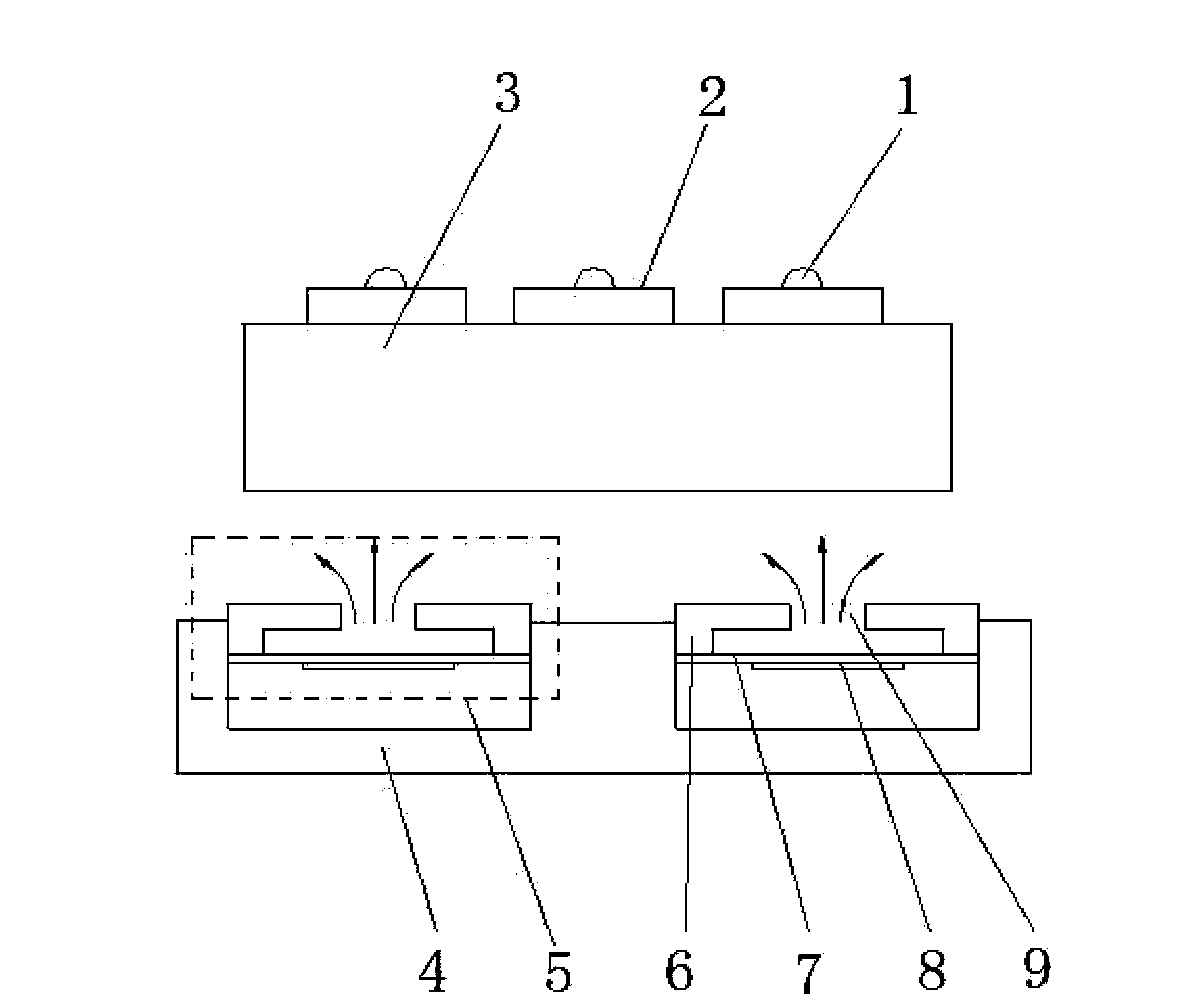

[0018] like figure 1 The heat dissipation system for LED street lights shown includes a plurality of LED chips 1 used as light sources for LED street lights. The lower sides of the plurality of LED chips 1 are fixedly provided with a substrate 2 that conducts heat generated by the LED chips 1 during operation. In the embodiment, the substrate 2 is preferably an aluminum substrate; the underside of the substrate 2 is provided with an integrated radiator 3 for dissipating heat, the lower surface of the substrate 2 is fixedly connected to the upper surface of the integrated radiator 3, and the The lower side of the integrated radiator 3 is provided with a plurality of synthetic jet radiators 5, the synthetic jet radiator 5 includes a synthetic jet outer wall 6 with an inverted concave structure, and the upper surface of the synthetic jet outer wall 6 is provided with a cavity mouth 9, so The lower side of the synthetic jet outer wall 6 is provided with an elastic diaphragm 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com