Ball valve and control method thereof

A control method and ball valve technology, applied in the field of valve machinery, can solve the problems of poor valve sealing wear resistance, perforation, valve body, valve seat weld impermeability, etc., to reduce gaps, small flow resistance, improve service life and The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

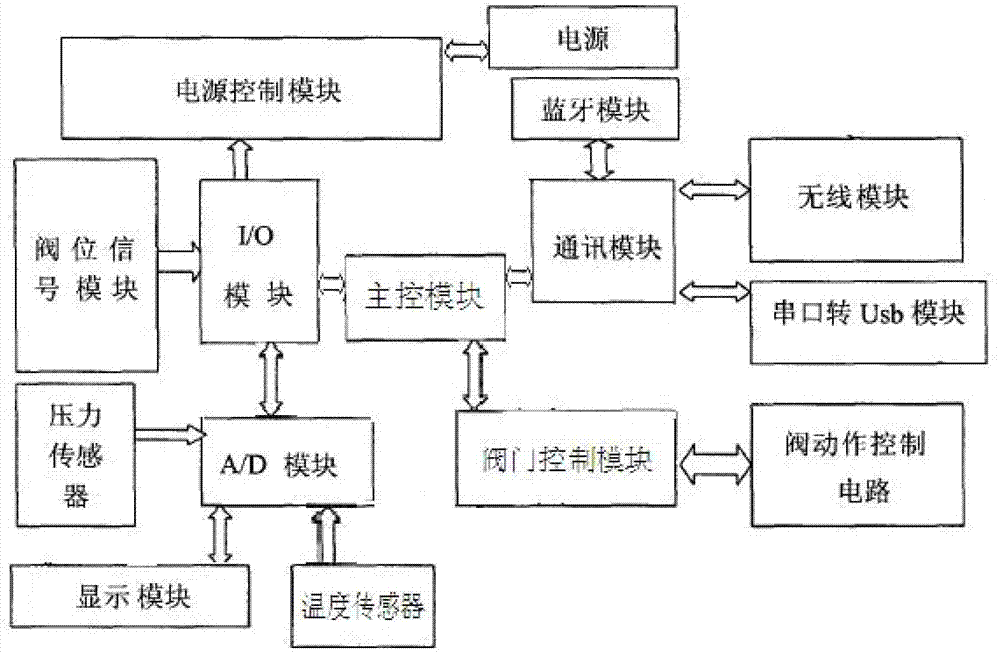

[0116] The cryogenic ball valve of the present invention includes a valve body, a valve cover, a valve seat assembly, a ball, a valve stem, a spring, a fixed shaft, a long neck bracket, a top bracket, a driving device, and the like. The valve body and the valve cover each have flow passages, and the valve body and the valve cover are connected through gaskets, studs and nuts. The ball is placed in the valve body, and there is a valve seat assembly on both sides of the ball, which are respectively connected to the inside of the valve body and the valve cover. The driving device is connected to the upper part of the valve stem through a key, and the lower end of the valve stem is connected to the ball. The rotation makes the valve stem and the ball rotate around the axis to realize the opening and closing of the valve at 90°.

[0117] The bottom surface of the upper part of the sphere in contact with the valve stem adopts an arc surface, and the two sides are corresponding paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com