Steel plate damping wall

A technology of damping walls and steel plates, applied in walls, building components, and earthquake resistance, can solve problems such as out-of-plane buckling, achieve the effects of reducing structural vibration, reducing yield displacement, and improving stability and energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

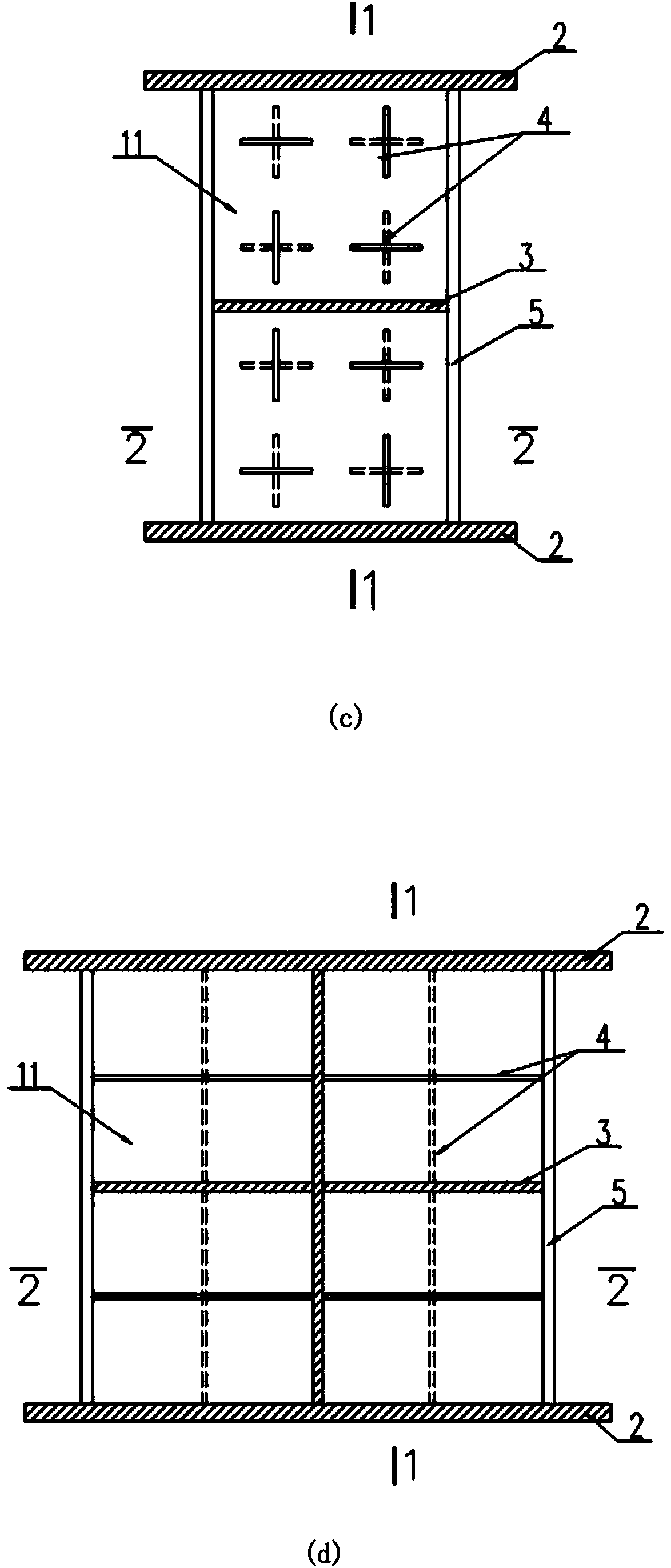

[0031] see figure 1 (a), figure 2 (a), image 3 As shown in (a), the outer surfaces of the embedded steel plates 11 of the two small cells are respectively provided with a horizontal stiffening plate 4 at the center line, and a vertical stiffening plate 4 is respectively provided at the center line of the inner surface. . The stiffeners 4 on both sides of the steel plates 11 embedded in the two small grids are respectively arranged in an anti-symmetrical "cross-shaped" cross.

Embodiment 2

[0033] see figure 1 (b), figure 2 (b), image 3 As shown in (b), on the outer surface of the two small grid embedded steel plates 11, a stiffening plate 4 is respectively arranged in the direction of the diagonal line, and a stiffening plate 4 is respectively arranged in the direction of the other diagonal line on the inner surface. plate 4. The stiffening plates 4 on both sides of the embedded steel plates 11 of the two small cells are respectively arranged with anti-diagonal lines intersecting.

Embodiment 3

[0035] see figure 1 (c), figure 2 (c), image 3 As shown in (c), two stiffening plates 4 in the horizontal direction and two stiffening plates 4 in the vertical direction are respectively arranged on the outer surface of the steel plate 11 embedded in the two small grids, and the four stiffening plates 4 are partially arranged in the following The center of the small cell embedded steel plate 11 is the inner side of the four corners of the small cell embedded steel plate 11 . There is no intersection between the stiffening plates 4 in the horizontal direction and the stiffening plates 4 in the vertical direction, the two stiffening plates 4 in the horizontal direction are obliquely symmetrical, and the two stiffening plates 4 in the vertical direction are obliquely symmetrical. On the inner side of the two small grid embedded steel plates 11, the number of stiffening plates 4 is the same as the number of stiffening plates 4 on the outer side, and the stiffening plate 4 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com