Thermal treatment method for improving plasticity of aluminum alloy plate material

A heat treatment method and technology for aluminum alloy sheets, applied in the field of metal materials, can solve the problems of inability to meet the high-end use requirements of processing deformation requirements, low plasticity, etc., and achieve the effect of reducing the effect of solid solution strengthening, reducing costs, and shortening the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of heat treatment method that improves the plasticity of aluminum alloy plate, this method comprises the following steps:

[0030] 1) Homogenization treatment: put the as-cast 5052 aluminum alloy in a heat treatment furnace at a temperature of 470°C, and perform homogenization treatment for 15 hours.

[0031] 2) Rolling: The homogenized aluminum alloy is rolled at room temperature, and the rolling deformation is 75%.

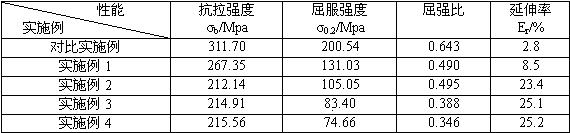

[0032] 3) Annealing treatment: the alloy was annealed at 250°C, kept for 4 hours, then taken out and air-cooled to room temperature. Comparing the annealed aluminum alloy with the directly rolled aluminum alloy without annealing treatment, the yield ratio decreased from 0.643 to 0.490, and the plasticity increased from 2.8% to 8.5%, which increased by 204%, and the plasticity improvement was more significant.

[0033] The metallographic photograph of the 5052 aluminum alloy processed through embodiment 1 is as follows figure 1 As sh...

Embodiment 2

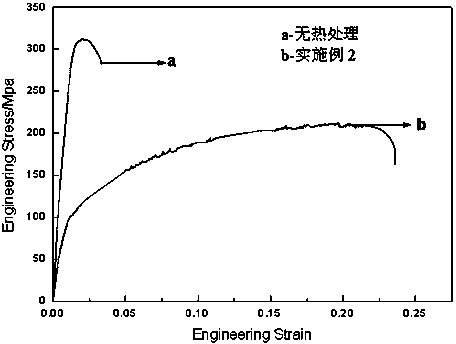

[0034] Embodiment 2: The same aluminum alloy alloy raw material, aluminum alloy homogenization treatment process and rolling process as in embodiment 1 are used, and the process parameters are completely the same. The above-mentioned treated aluminum alloy was stabilized and annealed at 300° C., kept for 4 hours, and then taken out and air-cooled to room temperature. Comparing the annealed aluminum alloy with the directly rolled aluminum alloy without annealing treatment, the yield ratio decreased from 0.643 to 0.495, the plasticity increased from 2.8% to 23.4%, and the plasticity increased by 736%, and the plasticity improvement was more obvious.

[0035] The metallographic photograph of the 5052 aluminum alloy processed through embodiment 2 is as follows figure 1 Shown in Figure d. Comparing Figure d with Figures a, b, and c, it can be found that the distribution of precipitated phases becomes more uniform as the temperature increases.

Embodiment 3

[0036] Embodiment 3: The same aluminum alloy raw materials, aluminum alloy homogenization treatment process and rolling process as in embodiment 1 are used, and the process parameters are completely the same. The above-mentioned treated aluminum alloy was stabilized and annealed at 350° C., kept for 4 hours, and then taken out and air-cooled to room temperature. Comparing the annealed aluminum alloy with the directly rolled aluminum alloy without annealing treatment, the yield ratio is reduced from 0.643 to 0.388, the plasticity is increased from 2.8% to 25.1%, and the plasticity is increased by 796%. The plasticity improvement is very significant.

[0037] The metallographic photograph of the 5052 aluminum alloy processed through embodiment 3 is as follows figure 1 Shown in Figure e. It can be seen from the figure e that the precipitated second phase not only increases in content but also has a more uniform distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield ratio | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com