TiO2 photocatalysis coating for degrading formaldehyde gas and preparation method thereof

A formaldehyde gas, photocatalytic technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of increasing the recombination probability of photogenerated holes h+vb, reducing the photocatalytic ability, reducing the photocatalytic effect, etc., to improve the product. Market competitiveness, good economic benefits, the effect of enhancing the response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

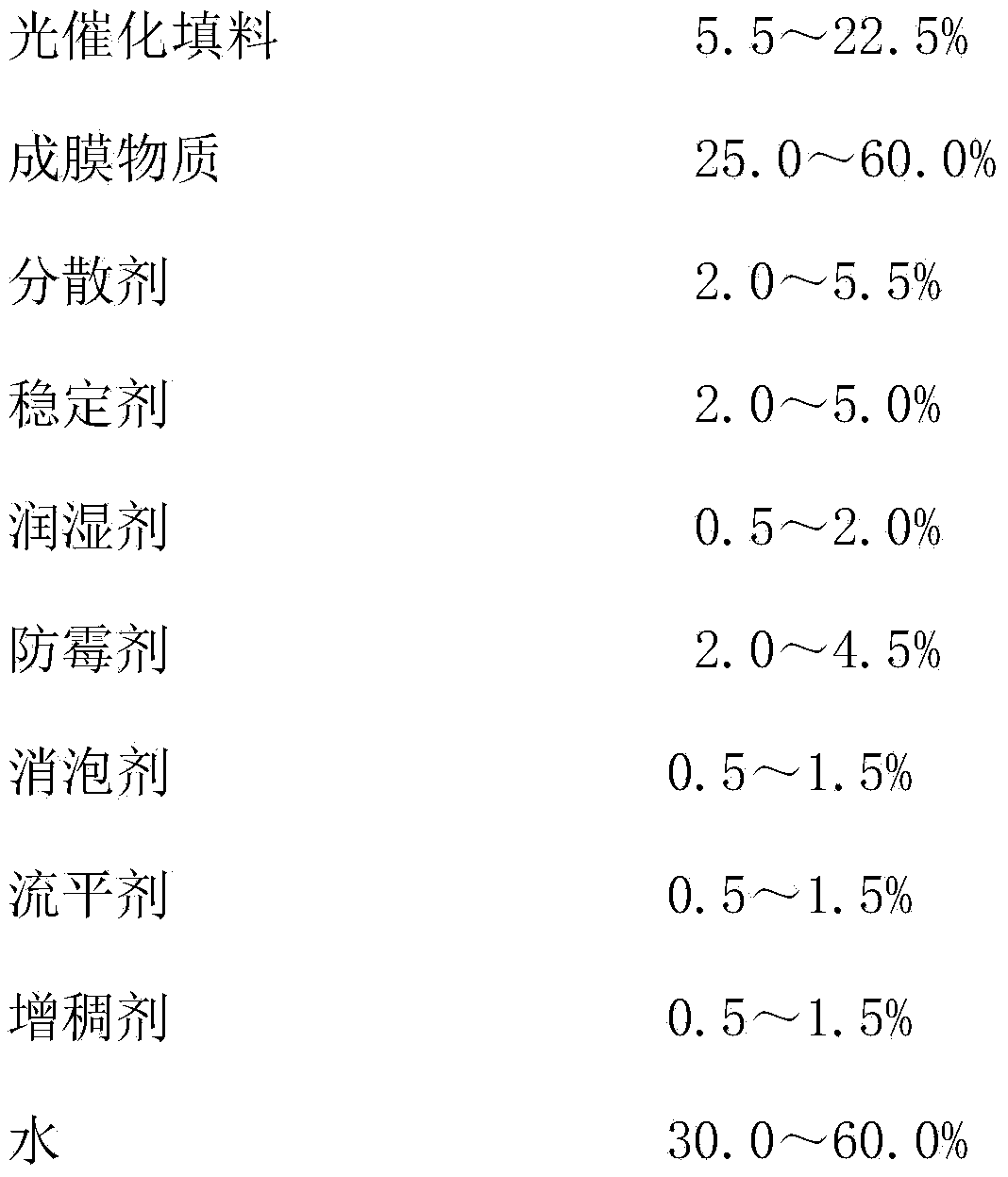

Method used

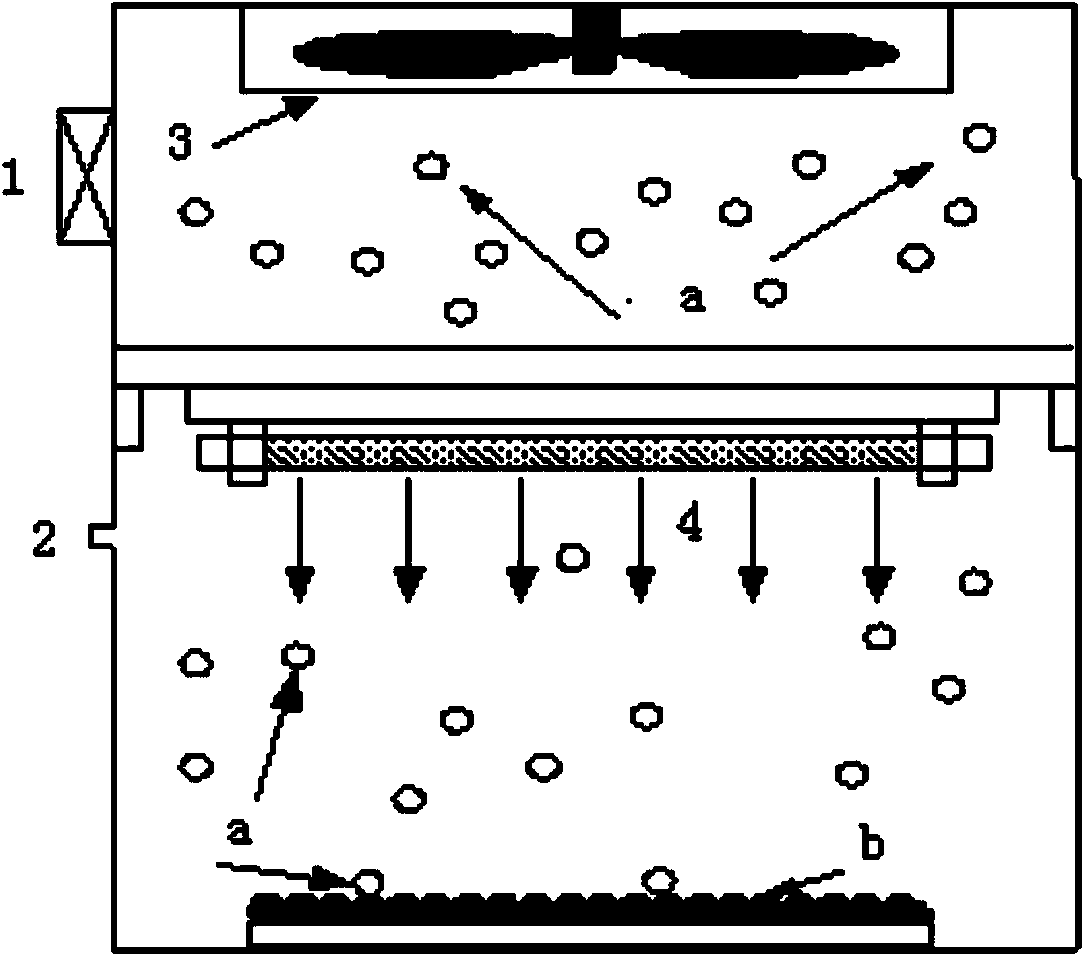

Image

Examples

Embodiment 1

[0034] Press V(Ti(C 4 h 9 O) 4): V(C 2 h 5 OH)=1:4 ratio of raw materials. Butyl titanate Ti(C 4 h 9 O) 4 Add dropwise to 3 / 4 of the amount of absolute ethanol C with vigorous stirring 2 h 5 OH, after stirring for 45min, a uniform transparent solution was obtained, and then dissolved Cu(NO 3 ) 2 ·3H 2 O and La(NO 3 ) 3 ·6H 2 O(Cu-La / TiO 2 The total molar percentage of Cu-La is 1%, the dilute hydrochloric acid solution (pH=4.5) of Cu and La molar ratio 3:1) is slowly added to the above solution under vigorous stirring, and the remaining 1 / 4 The amount of anhydrous ethanol is slowly added dropwise, after 10 minutes of dripping, vigorously stirred for 30 minutes, the obtained liquid sol is formed in the room for 5 days to form a xerogel, after suction filtration and washing, dry at 80°C for 10 hours in a blast drying oven, take it out and put it away Naturally cool and grind indoors, then put the sample into a medium-temperature experimental furnace and raise it ...

Embodiment 2

[0037] Press V(Ti(C 4 h 9 O) 4 ): V(C 2 h 5 OH)=1:4 ratio of raw materials. Butyl titanate Ti(C 4 h 9 O) 4 Add dropwise to 3 / 4 of the amount of absolute ethanol C with vigorous stirring 2 h 5 OH, after stirring for 45min, a uniform transparent solution was obtained, and then dissolved Cu(NO 3 ) 2 ·3H 2 O and La(NO 3 ) 3 ·6H 2 O(Cu-La / TiO 2 The total molar percentage of Cu-La is 1%, the dilute hydrochloric acid solution (pH=4.5) of Cu and La molar ratio 2:1) is slowly added to the above solution under vigorous stirring, vigorously stirred for 30min, and then the remaining 1 / 4 The amount of anhydrous ethanol is slowly added dropwise, after 10 minutes of dripping, vigorously stirred for 30 minutes, the obtained liquid sol is formed in the room for 5 days to form a xerogel, after suction filtration and washing, dry at 80°C for 10 hours in a blast drying oven, take it out and put it away Naturally cool and grind indoors, then put the sample into a medium-temperatur...

Embodiment 3

[0040] Press V(Ti(C 4 h 9 O) 4 ): V(C 2 h 5 OH)=1:4 ratio of raw materials. Butyl titanate Ti(C 4 h 9 O) 4 Add dropwise to 3 / 4 of the amount of absolute ethanol C with vigorous stirring 2 h 5 OH, after stirring for 45min, a uniform transparent solution was obtained, and then dissolved Cu(NO 3 ) 2 ·3H 2 O and La(NO 3 ) 3 ·6H 2 O(Cu-La / TiO 2 The total molar percentage of Cu-La is 1%, the dilute hydrochloric acid solution (pH=4.5) of Cu and La molar ratio 1:1) is slowly added to the above solution under vigorous stirring, vigorously stirred for 30min, and then the remaining 1 / 4 The amount of anhydrous ethanol is slowly added dropwise, after 10 minutes of dripping, vigorously stirred for 30 minutes, the obtained liquid sol is formed in the room for 5 days to form a xerogel, after suction filtration and washing, dry at 80°C for 10 hours in a blast drying oven, take it out and put it away Naturally cool and grind indoors, then put the sample into a medium-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com