Oxidized glutinous rice starch as well as preparation method and application thereof

A technology of glutinous rice starch and starch milk is applied in the field of modified starch to achieve the effects of improved reactivity, high chemical reactivity and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

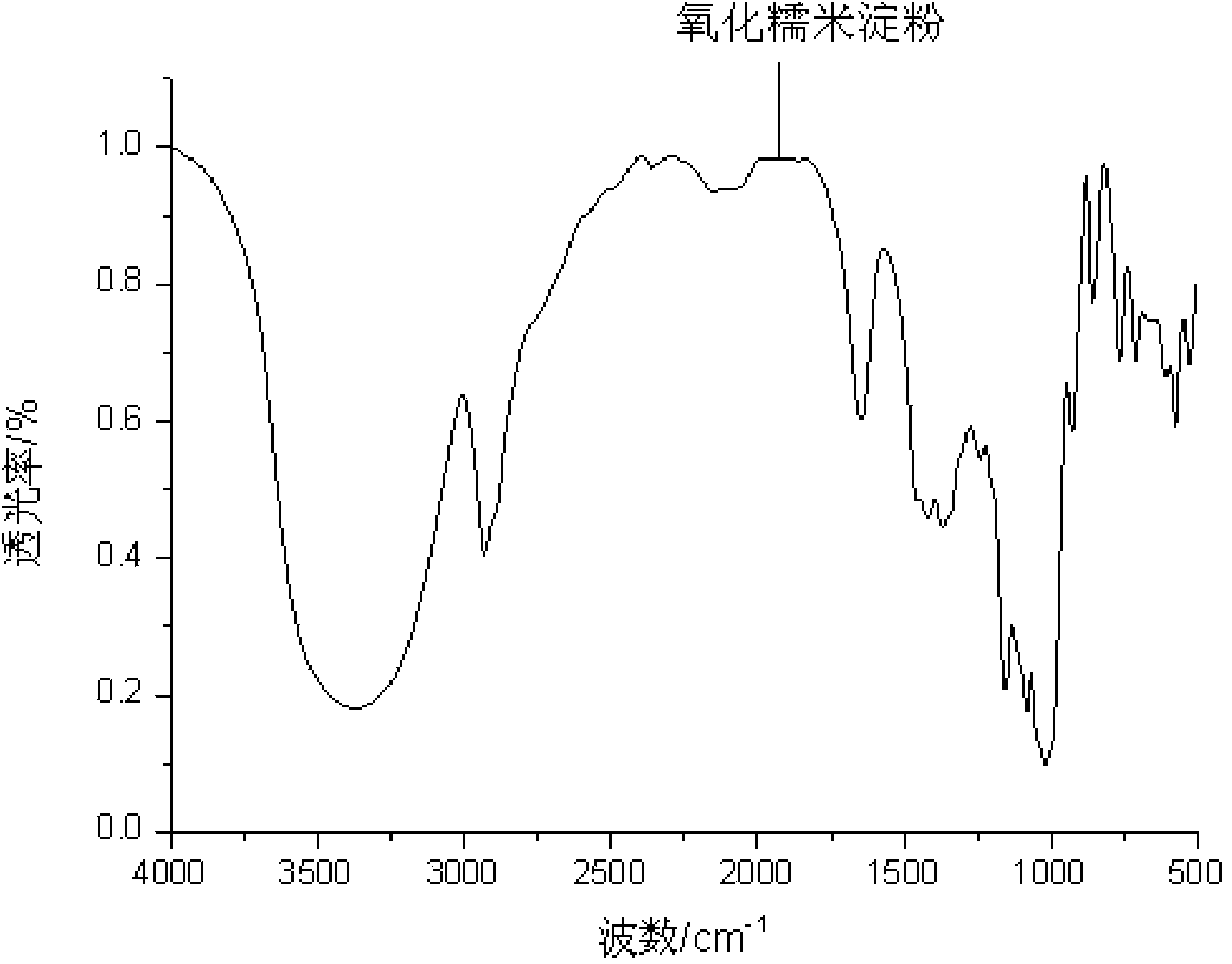

Image

Examples

Embodiment 1

[0039] A kind of oxidized glutinous rice starch, its preparation method is as follows:

[0040] (1) Mechanical activation: Activate the glutinous rice starch for 50 hours with a ball mill at room temperature under the condition that the revolution speed of the ball mill is 150r / min and the rotation speed is 300r / min; the inner diameter of the ball mill is 100mm, and the volume is 500ml; 50mm, the material of the grinding ball is agate;

[0041] (2) Adjust milk: Accurately weigh 30g of activated glutinous rice starch, and use deionized water to prepare starch milk with a mass fraction of 35%;

[0042] (3) Catalysis: Add 6ml of cobalt chloride solution with a mass fraction of 2% to the starch milk while stirring, and adjust the pH of the starch milk to 8 with a 3% mass fraction of sodium hydroxide solution;

[0043] (4) Oxidation: Slowly add 1ml of hydrogen peroxide with a mass fraction of 30% to the starch milk catalyzed in step (3), and react at a constant temperature of 40°C...

Embodiment 2

[0049] A kind of oxidized glutinous rice starch, its preparation method is as follows:

[0050] (1) Mechanical activation: use a ball mill to activate the glutinous rice starch for 55 hours under the conditions of ball mill revolution speed 150r / min and rotation speed 300r / min;

[0051] (2) Adjust milk: Accurately weigh 30g of activated glutinous rice starch, and use deionized water to prepare starch milk with a mass fraction of 35%;

[0052] (3) Catalysis: Add 9ml of cobalt chloride solution with a mass fraction of 3% to the starch milk while stirring, and adjust the pH of the starch milk to 8 with a 5% mass fraction of sodium hydroxide solution;

[0053] (4) Oxidation: Slowly add 1.2ml of hydrogen peroxide with a mass fraction of 40% to the starch milk catalyzed in step (3), and react at a constant temperature of 40°C for 1.5h to obtain the oxidized starch emulsion;

[0054] (5) Termination reaction: Use 0.1mol / L hydrochloric acid to neutralize the pH value of the oxidized ...

Embodiment 3

[0058] A kind of oxidized glutinous rice starch, its preparation method is as follows:

[0059] (1) Mechanical activation: use a ball mill to activate the glutinous rice starch for 60 hours under the conditions of ball mill revolution speed 150r / min and rotation speed 300r / min;

[0060] (2) Adjust milk: Accurately weigh 30g of activated glutinous rice starch, and use deionized water to prepare starch milk with a mass fraction of 35%;

[0061] (3) Catalysis: Add 9ml of ferrous sulfate solution with a mass fraction of 4% to the starch milk while stirring, and adjust the pH of the starch milk to 10 with a potassium hydroxide solution of 3% mass fraction;

[0062] (4) Oxidation: Slowly add 1.5ml of hydrogen peroxide with a mass fraction of 30% to the starch milk catalyzed in step (3), and react at a constant temperature of 45°C for 2 hours to obtain the oxidized starch emulsion;

[0063] (5) Termination reaction: Use 0.1mol / L hydrochloric acid to neutralize the pH value of the ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com