Rear-supporting-leg installation structure of overhead guard of forklift

A technology for installing structures and overhead guards, applied in the direction of lifting devices, etc., can solve problems such as poor impact resistance and easy collapse, and achieve the effects of avoiding bolt breakage, improving impact resistance, and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

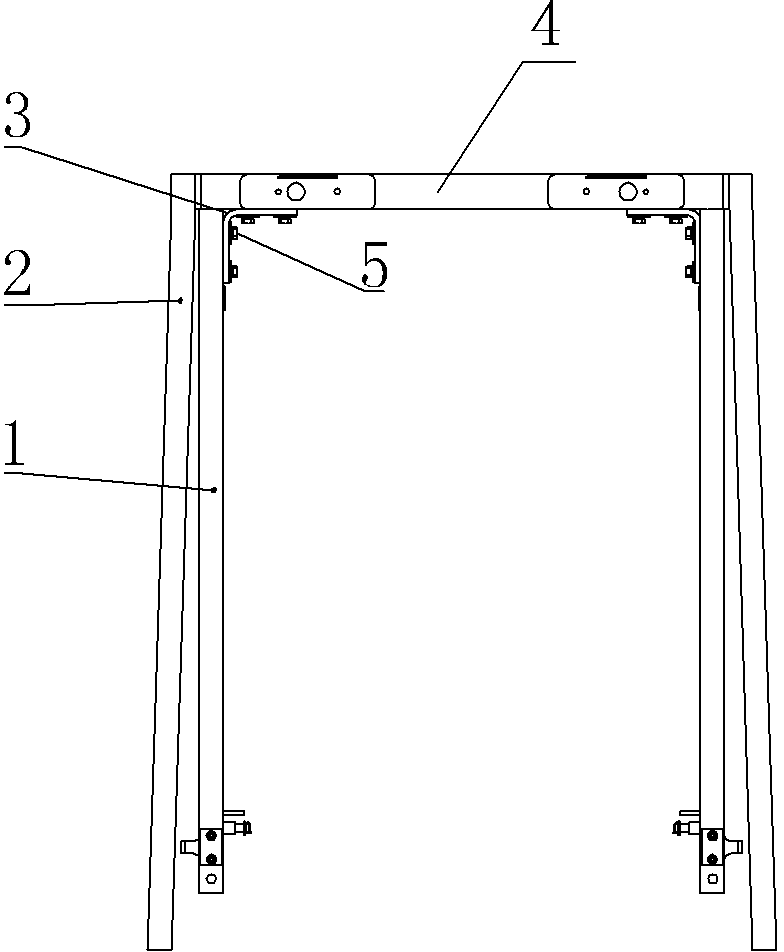

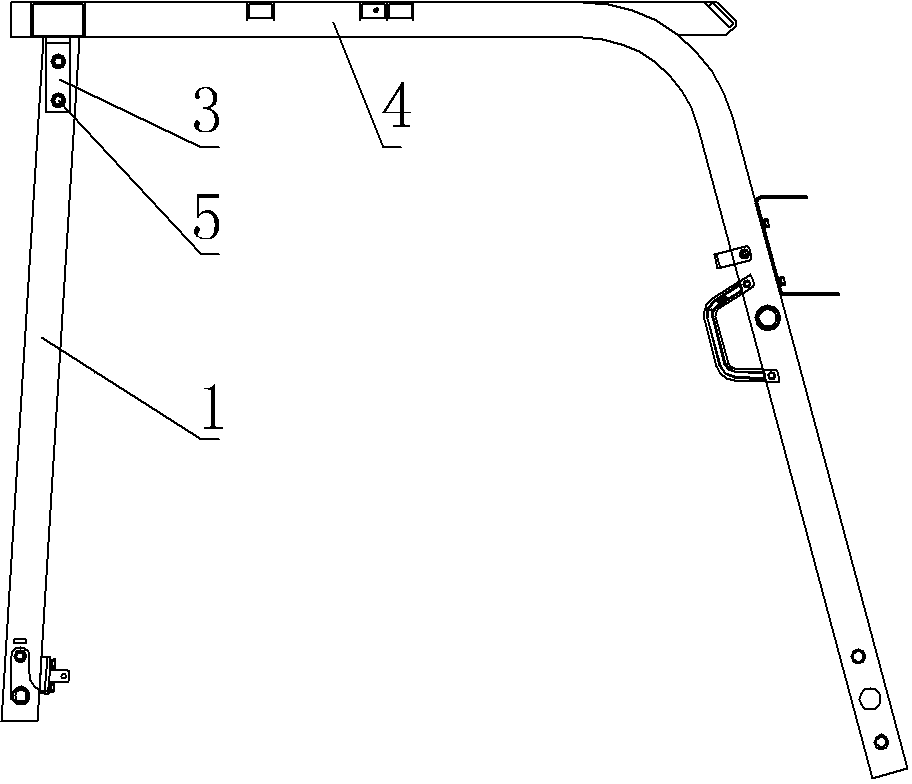

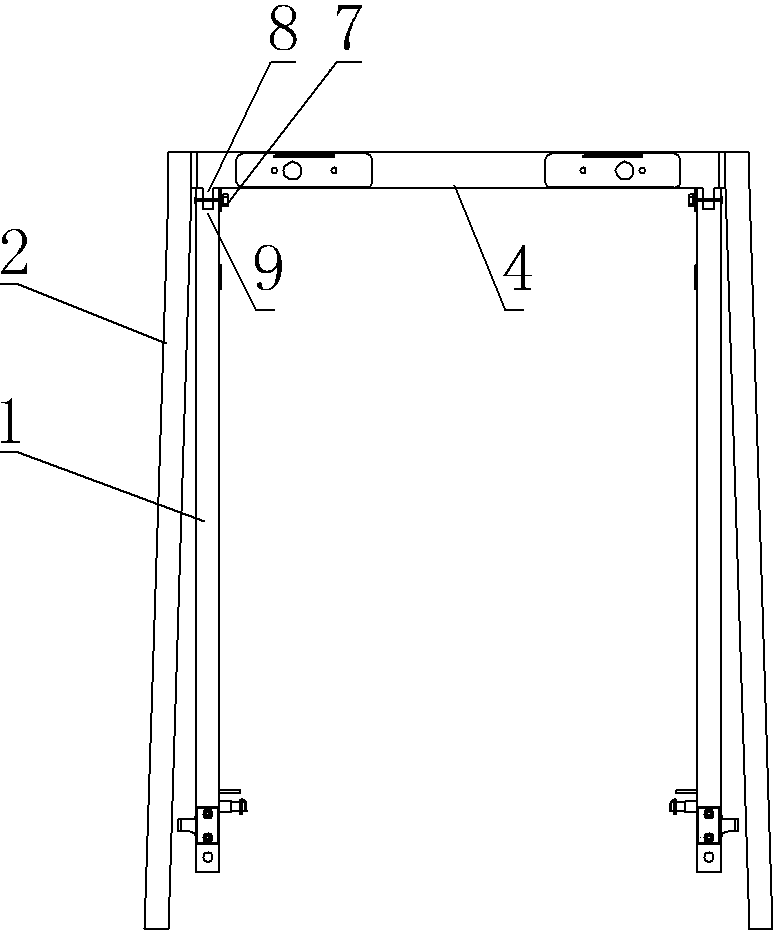

[0009] Such as image 3 As shown, the installation structure of the rear legs of the roof guard of a forklift includes a roof 4 of the roof guard, a rear leg 1, and a front support leg 2, and the front support legs 2 are located at both lateral ends of the roof guard 4 of the roof guard. It is characterized in that: The horizontal ends of the lower bottom surface of the roof 4 are rigidly connected with connecting blocks 8, and the upper end of the rear leg 1 is provided with a slot 9 corresponding to the connecting block 8. The roof 4 of the roof guard and the rear leg 1 pass through the connecting block 8 and the slot 9 snap-in connection, the connecting block 8 and the slot 9 are connected and fastened by the horizontal bolt 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com