Non-normal temperature test module

A technology of testing modules and high-temperature chambers, which is applied in the field of turntable semiconductor heating test sorting machines, can solve the problems that the airtightness cannot be well controlled, the material requirements of the pressure rod are relatively high, and the high-temperature test cannot be achieved, so as to improve the work. Efficiency and flexibility, reducing human error, avoiding the effects of temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

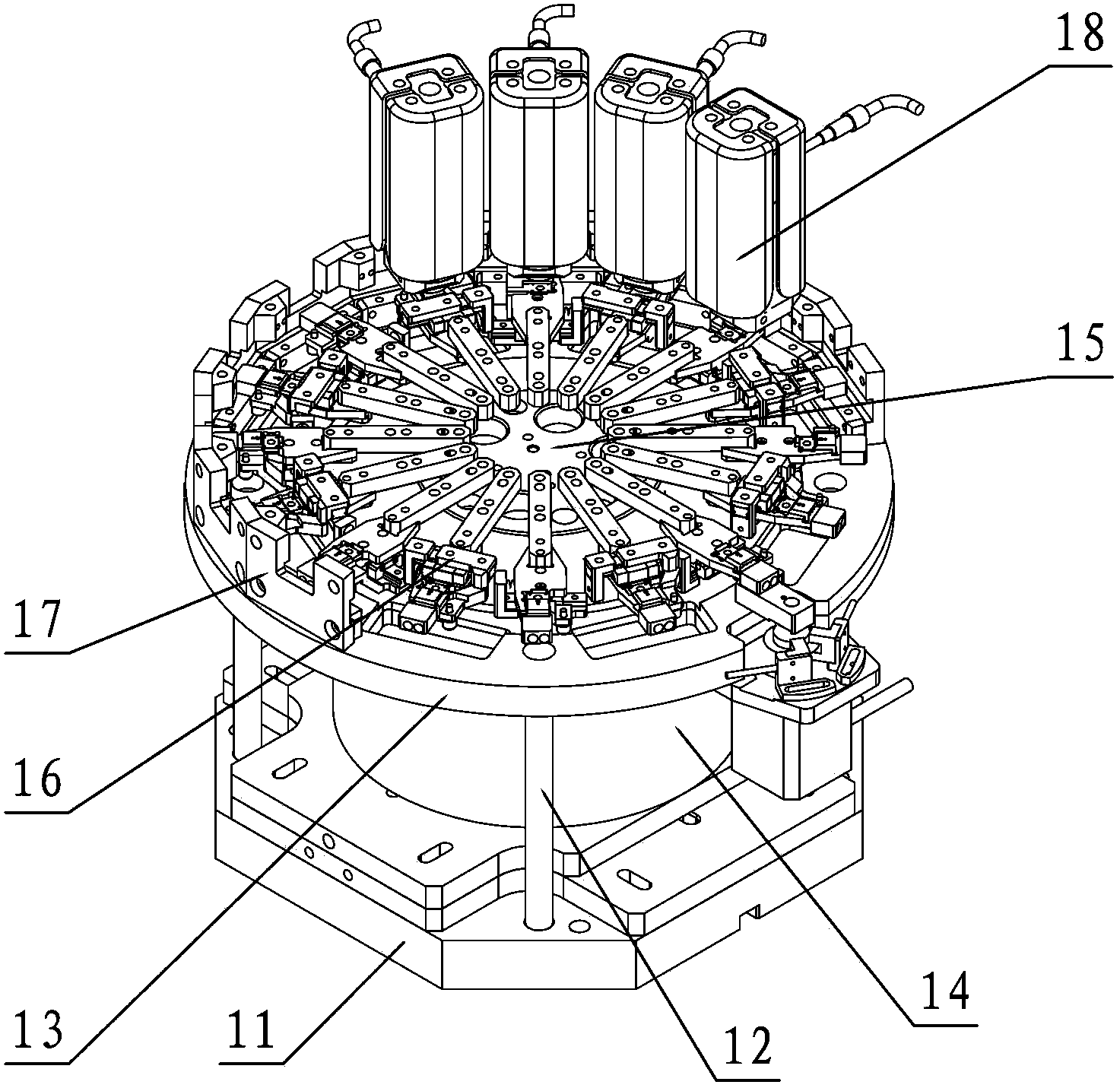

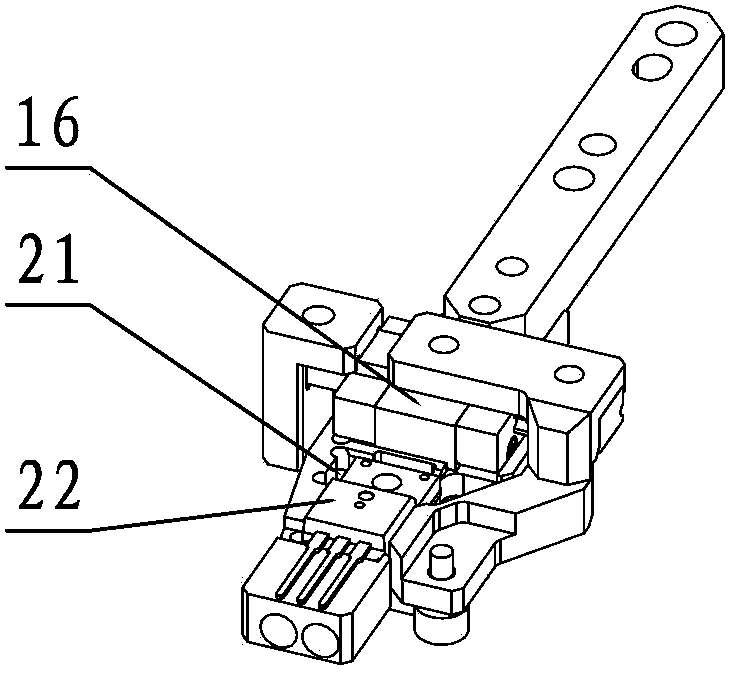

[0023] according to figure 1 and 2 , the very temperature test module provided by the present invention includes a base 11, a bracket 12 and a motor 14 installed on the base 11, a fixed base 13 supported by the bracket 12, a turntable 15 connected to the motor 14, and a A plurality of clip-type manipulators 16, the clip-type manipulator 16 is provided with a groove 21, and the electronic component 22 is fixed through the groove 21; the fixing seat 13 is provided with a plurality of mounting seats 18 corresponding to the clip-type manipulator 16, and a plurality of mounting seats 17 Evenly distributed on the edge of the fixed seat 13 in a circular shape, and the high temperature chamber 18 is installed on the mounting seat 17, and an intelligent heating system is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com