Variable-wavelength low-order shear-horizontal-wave electromagnetic acoustic transducer

A horizontal shear wave, electromagnetic ultrasonic technology, which is applied in the generation of ultrasonic/sonic/infrasonic waves, and the use of vibrating fluids. Sex and other issues, to achieve the effect of strong adaptability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] The content of the invention will be further described below in conjunction with a specific example.

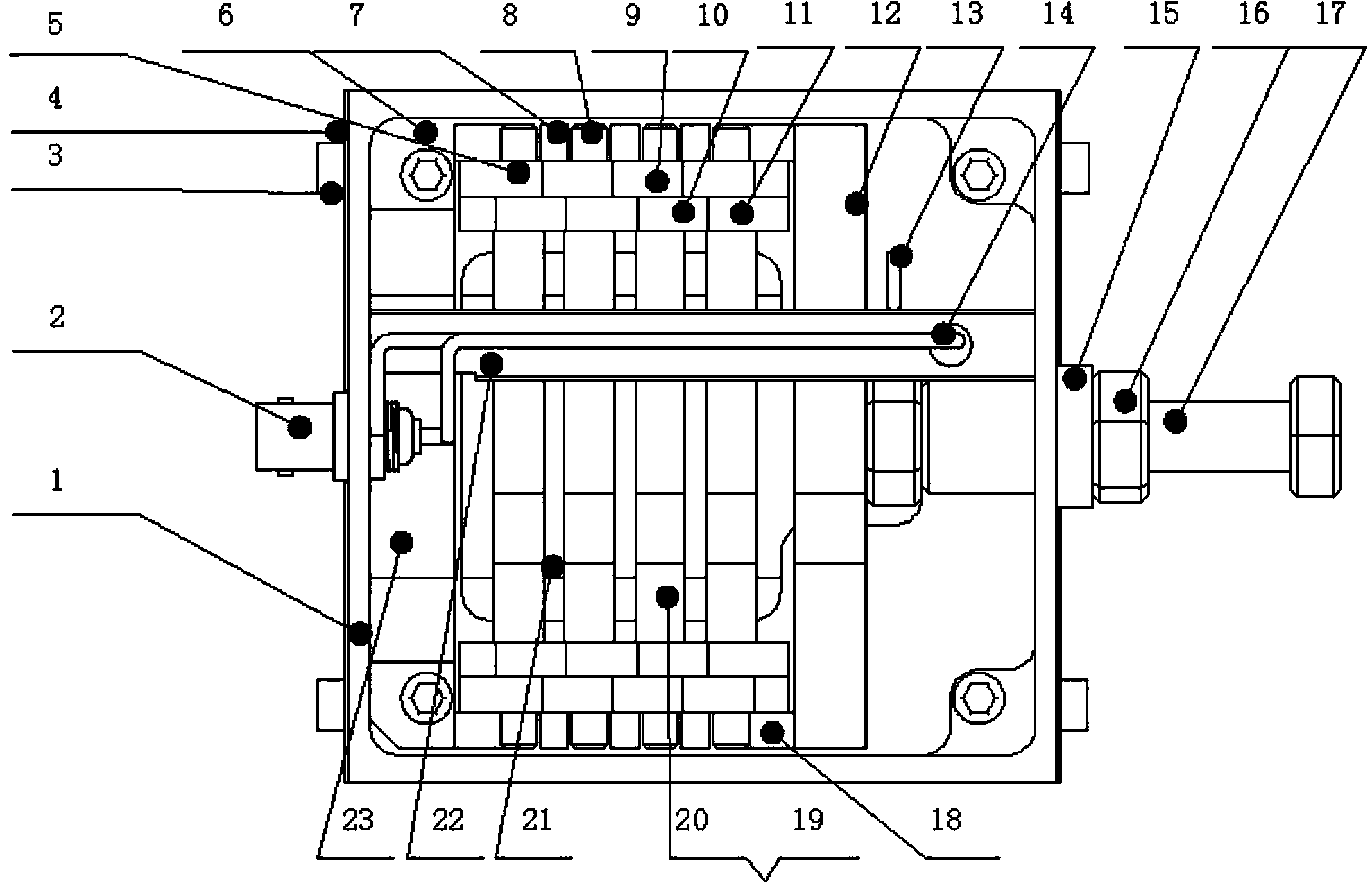

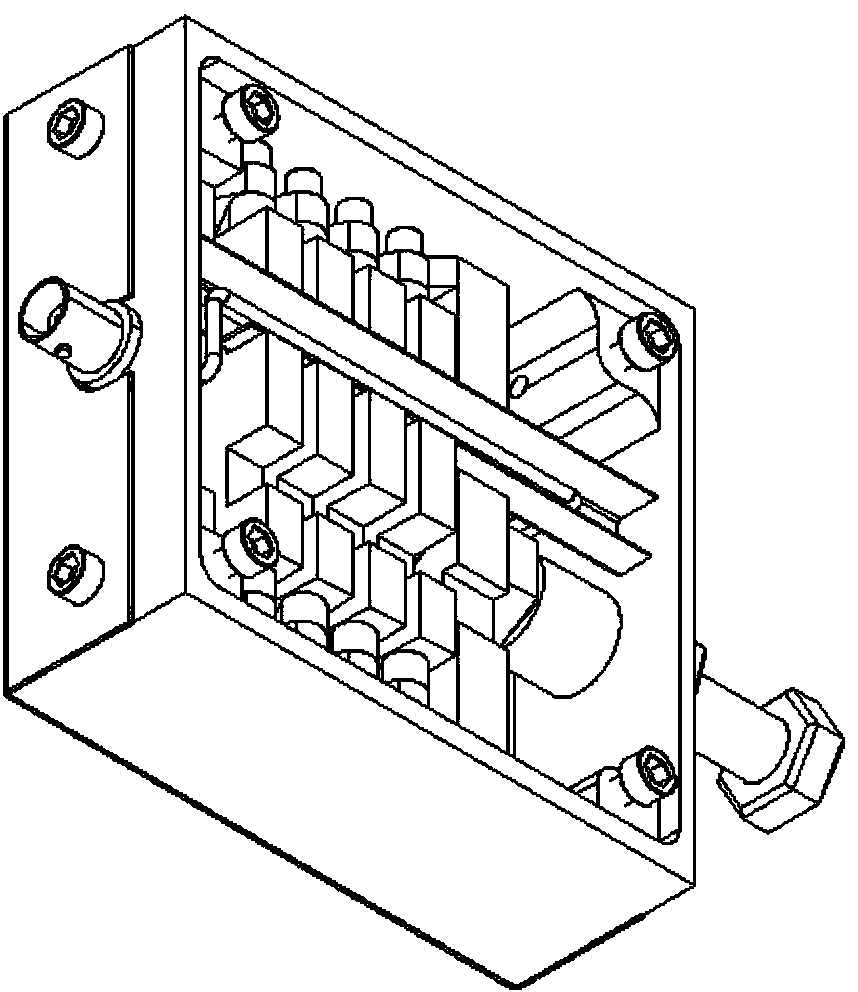

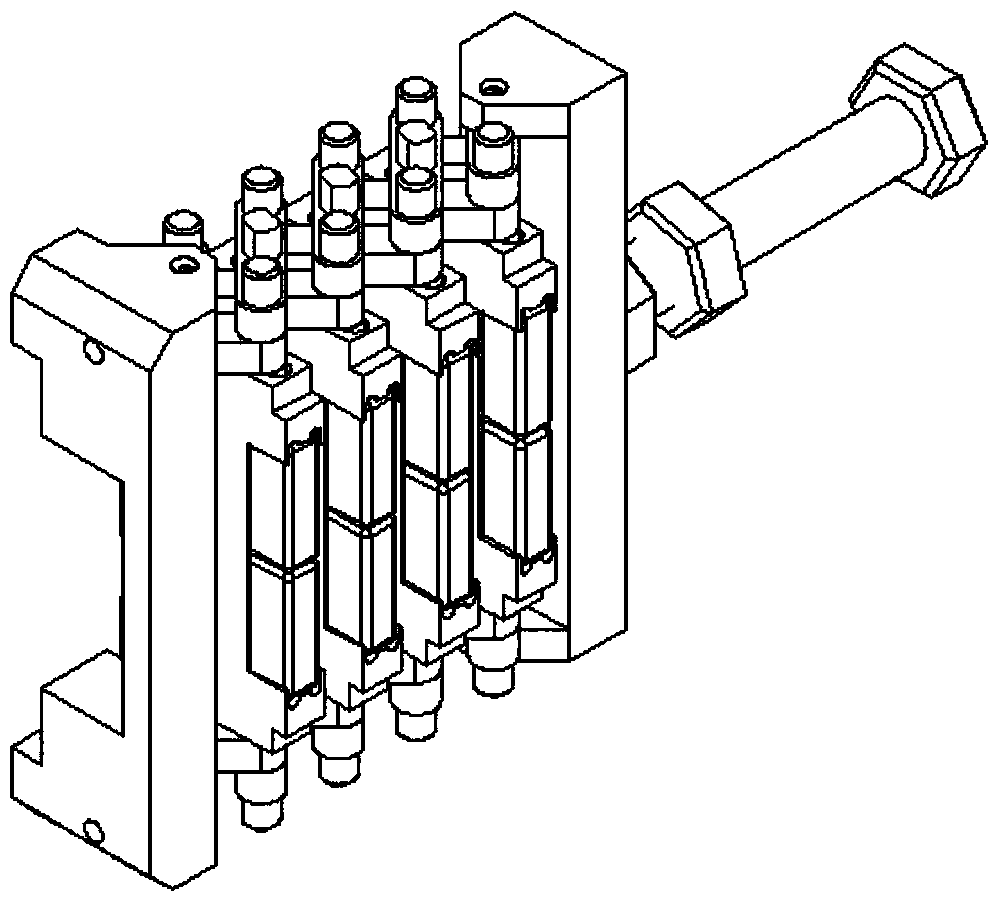

[0050] Solder two 15cm-long wires at the position of the PCB21 pad, and peel off the 0.5cm long wire sheath at the wire welding end 4cm away from the pad (such as Image 6 ), of course, you can also lead out the wires here separately; press figure 1 , figure 2 Assemble the other parts; shorten the distance between the magnets to the shortest; use an impedance analyzer to perform impedance matching, and weld the two pins of the capacitor to the free end of the two wires where the 0.5cm long skin is stripped or the lead wire is firmly welded. And use insulating tape to seal the exposed part of the wire and the metal pin of the capacitor; weld the free ends of the two 15cm long wires to the shaft of the BNC connector shell and the core respectively; install the end cover to complete the entire electromagnetic ultrasonic transducer. energy device assembly.

[0051] Use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com