Preparation method of microecological fermented feed by utilizing byproducts of corn deep-processing as raw materials

A fermented feed and production method technology, applied in the field of fermentation, can solve the problems of reducing the utilization value of by-products, not meeting energy conservation and emission reduction, and backward processing technology, achieving remarkable social and economic benefits, high comprehensive utilization efficiency, and improving production efficiency. The effect of food rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

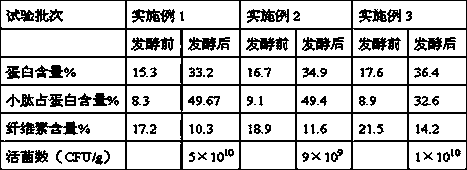

Embodiment 1

[0019] A method for producing micro-ecological fermented feed using corn deep-processing by-products as raw materials includes the following steps: (1) selecting three kinds of probiotics, Bacillus subtilis, Aspergillus oryzae and Rhizopus, and cultivating them on inclined planes and shake flasks to obtain two kinds of probiotics. Grade seeds and mix them in a ratio of 1:1:1.5. The inoculation amount of each level was 1%, the culture temperature was 32°C, the culture time was 40 hours, and the pH value of the culture medium was 5.5; The secondary seeds obtained from the primary and secondary cultures on slant planes and shake flasks were compounded according to the ratio of 1:1:1. The inoculation amount of each level is 5%, the culture temperature is 30°C, the culture time is 30 hours, and the pH value of the culture medium is 7; (3) Preparation of fermentation medium: various by-products such as corn bran that appear in the deep processing of corn , germ cake, corn steep liq...

Embodiment 2

[0024] A method for producing micro-ecological fermented feed using corn deep-processing by-products as raw materials includes the following steps: (1) selecting three kinds of probiotics, Bacillus subtilis, Aspergillus oryzae and Rhizopus, and cultivating them on inclined planes and shake flasks to obtain two kinds of probiotics. Grade seeds and mix them in a ratio of 1:2:3. The inoculation amount of each level was 2%, the culture temperature was 35°C, the culture time was 35 hours, and the pH value of the culture medium was 5.5; The secondary seeds obtained from the primary and secondary cultures of slant and shake flasks were compounded according to the ratio of 1:4:2. The inoculation amount of each level is 4%, the culture temperature is 28°C, the culture time is 35 hours, and the pH value of the culture medium is 5.8; (3) Preparation of fermentation medium: various by-products such as corn bran that appear in the deep processing of corn , germ cake, corn steep liquor, an...

Embodiment 3

[0029] A method for producing micro-ecological fermented feed using corn deep-processing by-products as raw materials includes the following steps: (1) selecting three kinds of probiotics, Bacillus subtilis, Aspergillus oryzae and Rhizopus, and cultivating them on inclined planes and shake flasks to obtain two kinds of probiotics. Grade seeds and mix them according to the ratio of 1:1.5:2. The inoculation amount of each level was 5%, the culture temperature was 37°C, the culture time was 24 hours, and the pH value of the culture medium was 5.9; The secondary seeds obtained from the primary and secondary cultures on slant planes and shake flasks were compounded according to the ratio of 1:3:1.5. The inoculation amount of each level is 4%, the culture temperature is 32°C, the culture time is 33 hours, and the pH value of the medium is 5.4; (3) Preparation of fermentation medium: various by-products such as corn bran that appear in the deep processing of corn , germ cake, corn s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com