Fruit-vegetable processed cheese spread and preparation method thereof

A processed cheese and spread type technology, which is applied in the field of fruit and vegetable spread type processed cheese and its preparation, and can solve the problems of poor taste, color and texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

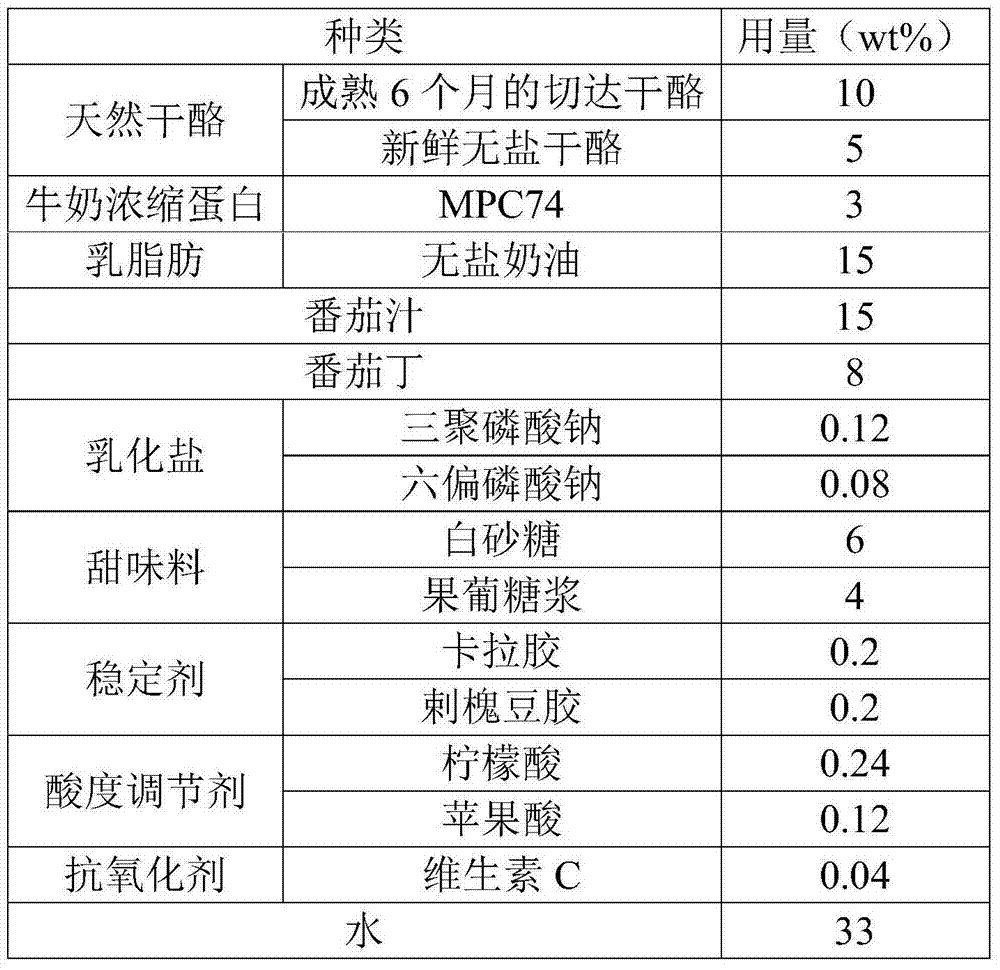

[0051] raw material:

[0052]

[0053] Preparation Process:

[0054] ① Finely cut the natural cheese and cream, then melt and mix with emulsifying salt, sweetener, milk protein concentrate, stabilizer and water at 65°C and 3000rpm stirring speed for 8min to obtain slurry A;

[0055] ②Add an acidity regulator at a stirring speed of 900rpm, stir evenly, heat up to 90°C, homogenize while hot at 20MPa, pasteurize at 88°C for 2min, and obtain slurry B;

[0056] ③Squeeze fresh tomatoes (the freshness is: the time from juicing to high-pressure treatment is no more than 4 hours) at room temperature to extract juice, and after extracting juice, filter through a single layer of gauze to obtain the desired tomato juice. The tomato juice is mixed with Diced tomatoes (cut from fresh tomatoes, 4mm*4mm*4mm) and antioxidants are mixed and subjected to ultra-high pressure treatment at 450MPa for 20 minutes; mixed with the slurry B obtained in step (2) evenly, stirred at 78°C and 1500rpm fo...

Embodiment 2

[0059] raw material:

[0060]

[0061] Preparation Process:

[0062] ① Finely cut the natural cheese and butter, then melt and mix with emulsified salt, sweetener, milk protein concentrate, stabilizer, pigment, flavor and water at 70°C and 1500rpm for 5 minutes at a stirring speed to obtain slurry A ;

[0063] ②Add acidity regulator and seasoning (Brix≥70, Shaanxi Haisheng Fruit Industry Development Co., Ltd.) at a stirring speed of 1200rpm, stir again evenly, heat up to 82°C, homogenize while hot at 18MPa, and homogenize at 80°C Next, pasteurize for 10 minutes to obtain slurry B;

[0064] ③Squeeze fresh tomatoes (the freshness is: the time from juicing to high-pressure treatment is no more than 4 hours) at room temperature to extract juice, and after extracting juice, filter through a single layer of gauze to obtain the desired tomato juice. The tomato juice is mixed with Diced tomatoes (cut from fresh tomatoes, 4mm*4mm*4mm) and antioxidants are mixed and subjected to u...

Embodiment 3

[0067] raw material:

[0068]

[0069]

[0070] Preparation Process:

[0071] ① Subdivide and cut the natural cheese, then melt and mix it with cream, emulsifying salt, sweetener, milk protein concentrate, stabilizer, essence and water at 68°C and 1800rpm stirring speed for 6min to obtain slurry A;

[0072] ② Add acidity regulator and concentrated fruit juice at a stirring speed of 600rpm, stir again evenly, heat up to 87°C, homogenize while hot at 15MPa, pasteurize at 85°C for 6min, and obtain slurry B;

[0073] ③Squeeze fresh tomatoes (the freshness is: the time from juicing to high-pressure treatment is no more than 4 hours) at room temperature to extract juice, and after extracting juice, filter through a single layer of gauze to obtain the desired tomato juice. The tomato juice is mixed with Diced tomatoes (cut from fresh tomatoes, 4mm*4mm*4mm) and antioxidants are mixed and subjected to ultra-high pressure treatment at 450MPa for 18 minutes; mixed with the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com