Heat-conducting device for an absorber and method for the production thereof

A technology for absorbers and solar collectors, applied in the field of manufacturing heat conduction devices, can solve problems such as different cross-sections or thicknesses, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

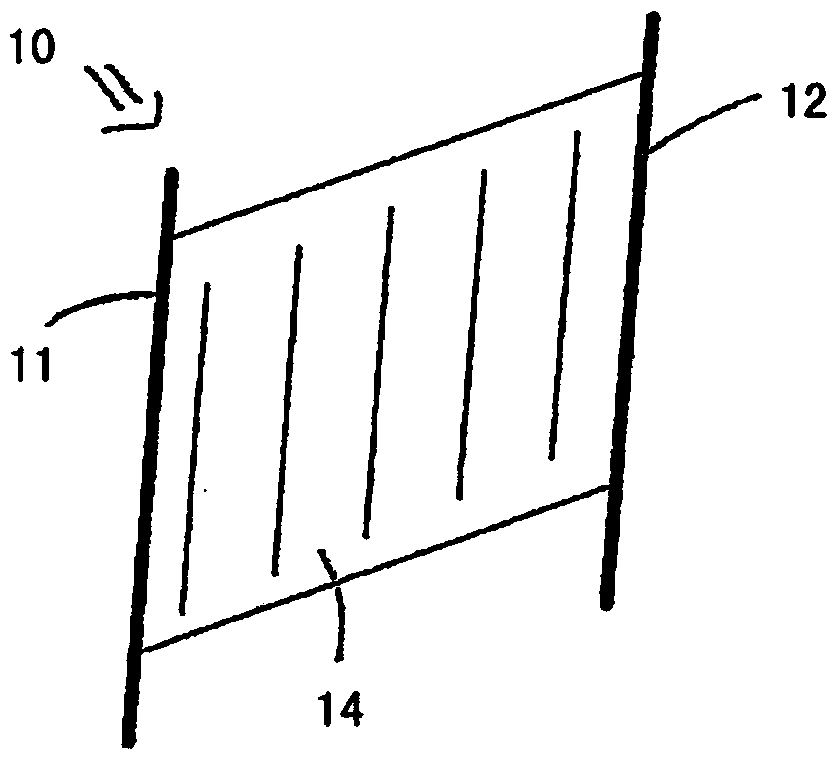

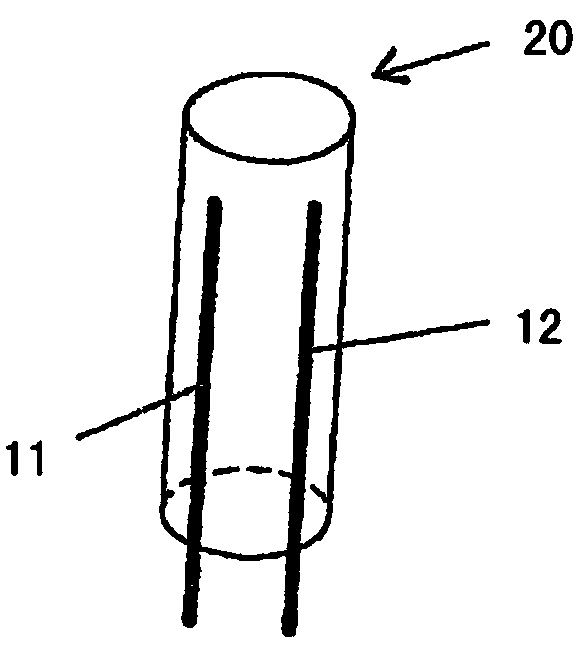

[0030] figure 1 Shown is a heat conduction device 10 according to the invention for the flow of a heat transfer medium of a planar absorber of a solar collector, said heat conduction device comprising a first collecting tube 11 for introducing the heat transfer medium and a A second collecting pipe 12 for the heat transfer medium, wherein the collecting pipes 11 , 12 each have at least one lateral opening not shown in this figure, through which the collecting pipe communicates with a likewise not shown Hollow chamber connection. The hollow chamber is formed in a one-piece plastic body 14 in which the two collecting tubes 11 , 12 are accommodated.

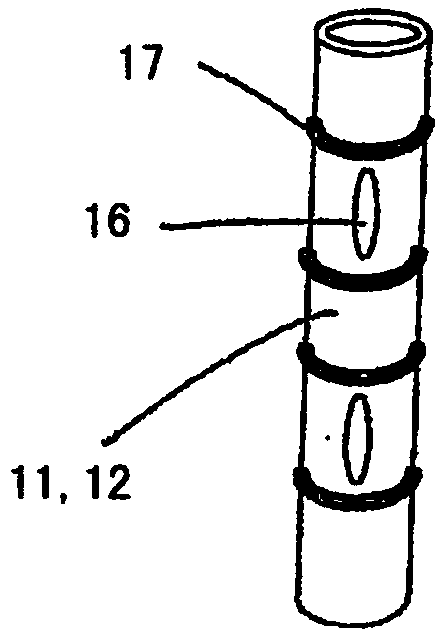

[0031] figure 2A side view of one collecting pipe 11 , 12 of the heat conducting device according to the invention is shown. The collecting tubes 11 , 12 have two lateral openings 16 . The lateral openings 16 are each designed as elongated holes in this example. However, any other configuration is also conceivable as long as i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com