T/R assembly integrated air tightness packaging structure resistant to overload

An encapsulation structure and air tightness technology, which can be applied to antenna supports/installation devices, semiconductor/solid-state device parts, electrical components, etc. Complex structure and other problems, to achieve the effect of improving microwave characteristics, improving reliability, and shortening transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

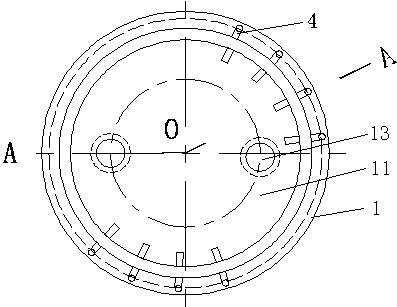

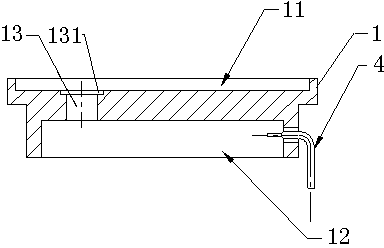

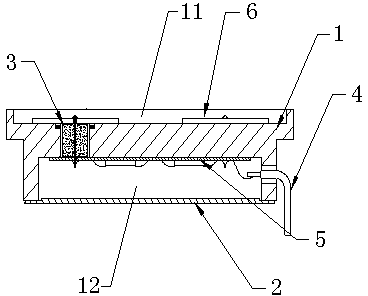

[0028] The invention adopts a specially designed circular metal shell 1, the receiving / transmitting antenna and the signal processing unit are respectively arranged on both sides of the shell, and the microwave insulator is used for signal transmission between the two parts, and the microwave insulator is sintered on the shell by eutectic welding. , The signal processing unit is an airtight structure, and the shell can be packaged by parallel seam welding or laser welding. The intermediate frequency signal output and control signal input of the T / R component adopts L-shaped pins, and the signal processing unit substrate adopts wire bonding Interconnected, the process flow is like Image 6 Shown....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com