Coal-to-gas energy saving and environmental protection boiler

An energy-saving and environmentally friendly coal-to-gas technology, applied in the boiler field, can solve problems such as insufficient coal dry distillation gasification, low coal thermal efficiency, and many floating particles, and achieve the effects of improving coal thermal efficiency, prolonging residence time, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

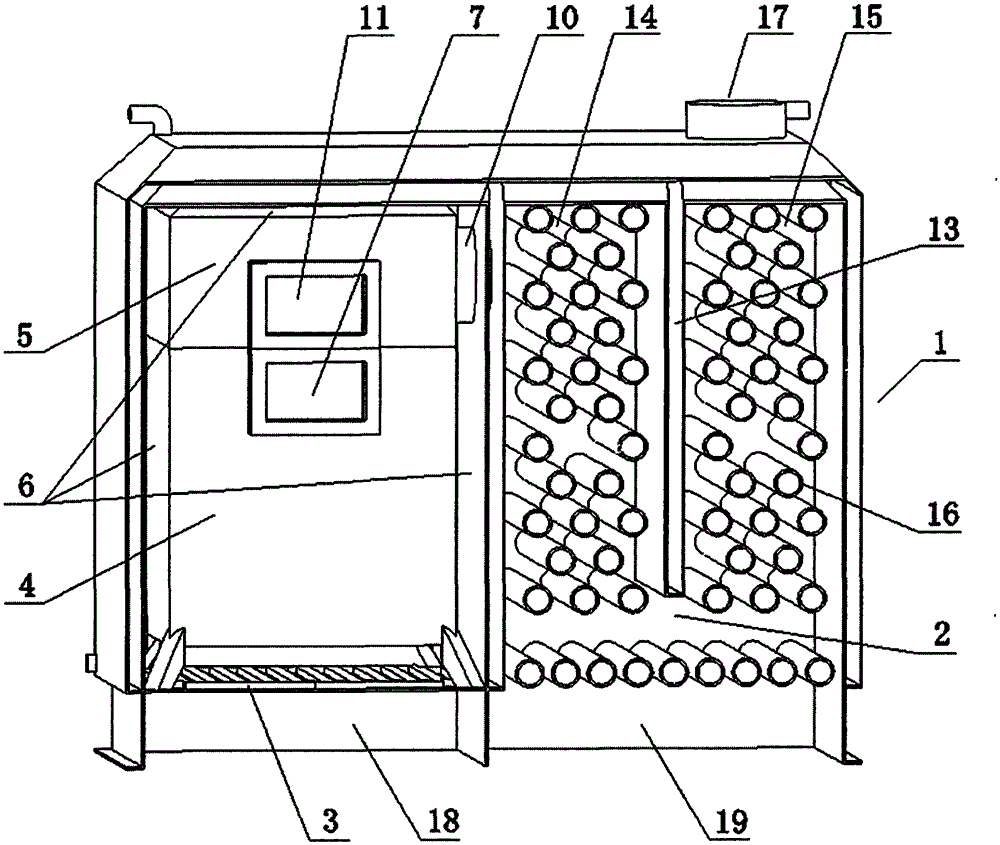

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

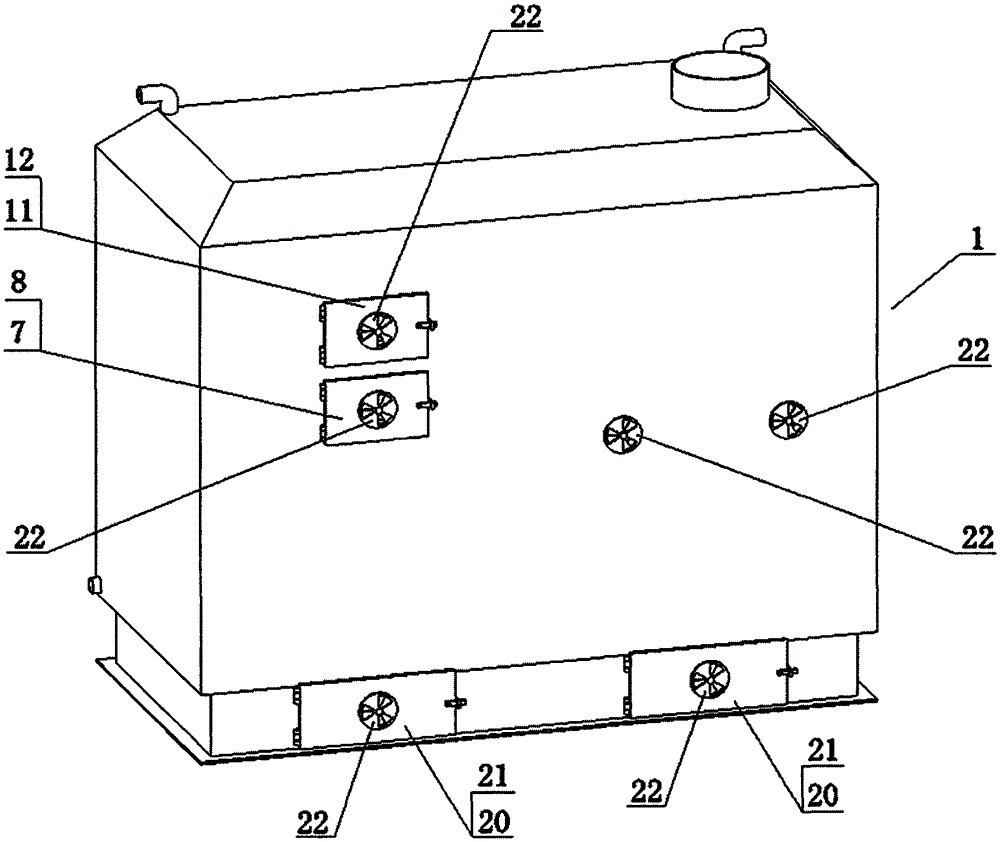

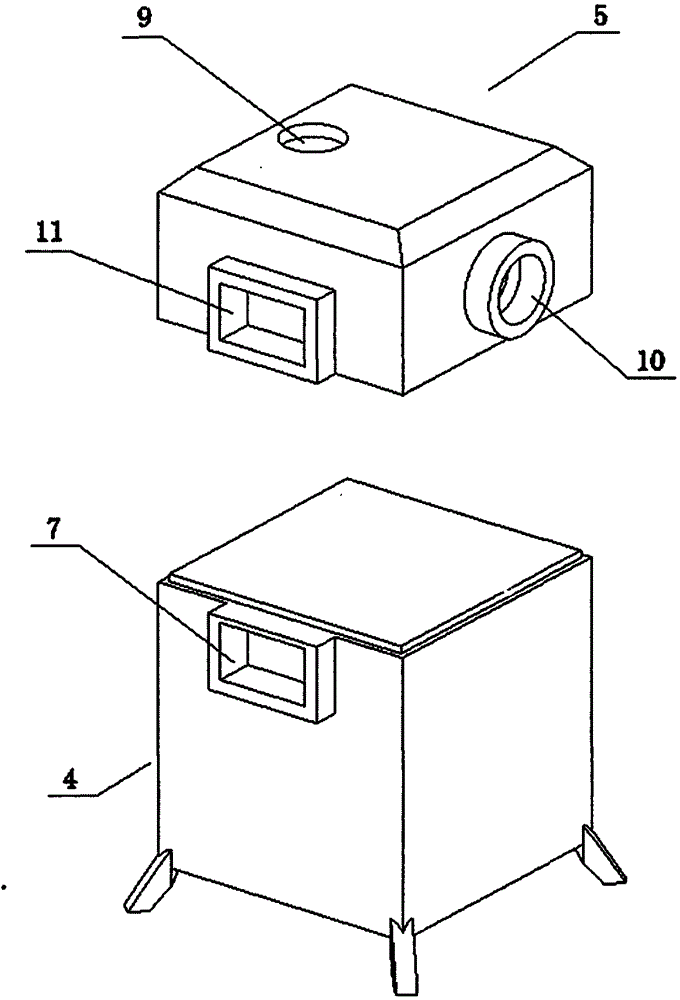

[0021] A coal-to-gas energy-saving and environmentally friendly boiler, which includes a water jacket furnace body 1, one side of the water jacket furnace body 1 is a gasification combustion furnace chamber, and the other side is a heat exchange chamber 2; the bottom of the gasification combustion furnace chamber is equipped with Fire grate 3, a refractory material gasification chamber 4 with a lower bottom opening is set aside at the top of the fire grate 3 with a height of 8 cm, and the upper part of the refractory material gasification chamber 4 is a refractory material combustion chamber 5, refractory material gasification chamber 4 and refractory material combustion chamber There is a flame gas channel 6 around the 5 and the top of the refractory material combustion chamber 5; the upper side of the refractory material gasification chamber 4 is provided with a coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com