A kind of method of amphiphilic copolymer modifying graphene modified epoxy resin

A technology of graphene modification and epoxy resin, which is applied in the surface modification and dispersion of graphene, and the preparation of graphene/epoxy resin composite materials, which can solve the problem of graphene's easy aggregation and poor dispersion performance, and its inability to exert its superiority Performance and other issues, to achieve the effect of easy mass production, high yield, and wide process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

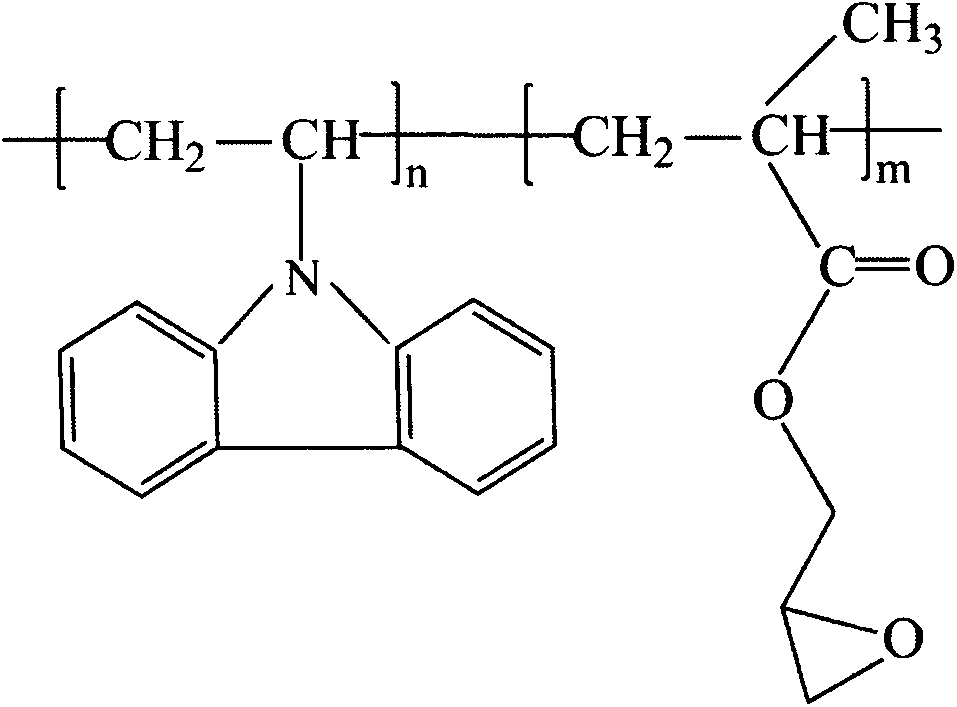

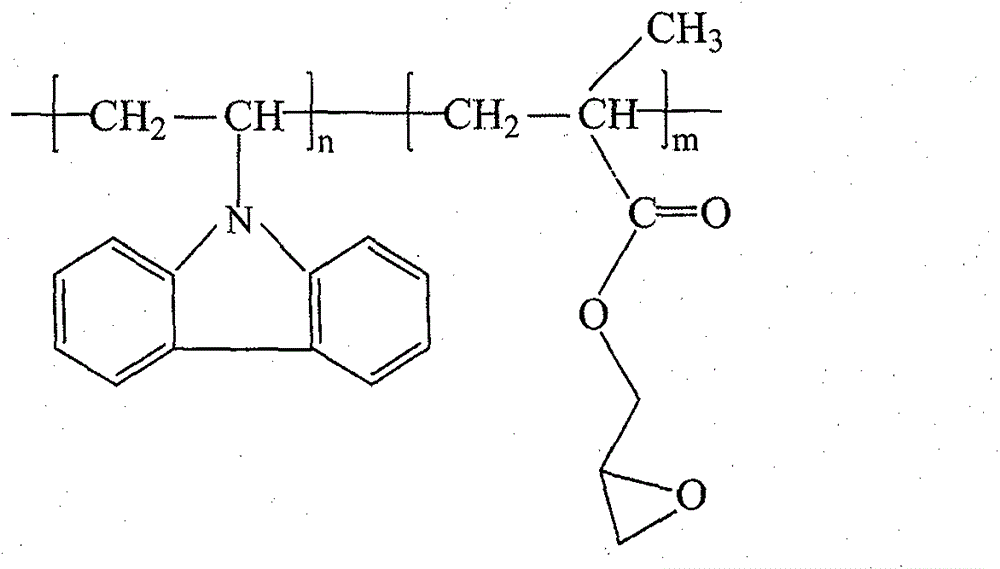

[0015] In the first step, stir and dissolve 0.5g of glycidyl methacrylate, 0.5g of vinyl carbazole, and 0.01g of azobisisobutyronitrile in 20mL of tetrahydrofuran, and pass through N 2 5min-30min, sealed, reacted at 70°C for 12h, precipitated after the reaction, dried in a vacuum oven at 20-80°C to obtain the amphiphilic copolymer.

[0016] In the second step, 0.1 g of graphene oxide and 1 g of amphiphilic copolymer were dispersed in tetrahydrofuran, hydrazine hydrate was added, reacted at 70 ° C for 12 h, cooled and centrifuged, and black powder was obtained after drying, which was amphiphilic copolymer modified graphene.

[0017] In the third step, the amphiphilic copolymer modified graphene is finally added to the bisphenol A epoxy resin (E51), decompressed and pumped, and the hexahydrophthalic anhydride curing agent is added to mix evenly and then poured into the mold, wherein the epoxy resin , curing agent and amphiphilic polymer-modified graphene in a weight ratio of 100...

Embodiment 2

[0019] In the first step, stir and dissolve 0.5g glycidyl methacrylate, 1g vinyl carbazole, and 0.015g azobisisobutyronitrile in 20mL tetrahydrofuran, pass N 2 5min-30min, sealed, reacted at 70°C for 12h, precipitated after the reaction, dried in a vacuum oven at 20-80°C to obtain the amphiphilic copolymer.

[0020] In the second step, 0.1 g of graphene oxide and 0.5 g of amphiphilic copolymer were dispersed in tetrahydrofuran, hydrazine hydrate was added, reacted at 70 ° C for 12 h, cooled and centrifuged, and black powder was obtained after drying, which was amphiphilic copolymer modified graphene.

[0021] In the third step, the amphiphilic copolymer modified graphene is finally added to the bisphenol A epoxy resin (E51), decompressed and pumped, and the tetrahydrophthalic anhydride curing agent is added to mix evenly and then poured into the mold, wherein the epoxy resin , curing agent and amphiphilic polymer-modified graphene in a weight ratio of 100:95:1, fully mixed and...

Embodiment 3

[0023] In the first step, stir and dissolve 0.5g glycidyl methacrylate, 1g vinyl carbazole, and 0.015g azobisisobutyronitrile in 20mL tetrahydrofuran, pass N 2 5min-30min, sealed, reacted at 70°C for 12h, precipitated after the reaction, dried in a vacuum oven at 20-80°C to obtain the amphiphilic copolymer.

[0024] In the second step, 0.1 g of graphene oxide and 0.5 g of amphiphilic copolymer were dispersed in tetrahydrofuran, hydrazine hydrate was added, reacted at 70 ° C for 12 h, cooled and centrifuged, and black powder was obtained after drying, which was amphiphilic copolymer modified graphene.

[0025] In the third step, the amphiphilic copolymer modified graphene is finally added to the bisphenol A epoxy resin (E51), decompressed and pumped, and the hexahydrophthalic anhydride curing agent is added to mix evenly and then poured into the mold, wherein the epoxy resin , the curing agent and the amphiphilic polymer-modified graphene in a weight ratio of 100:95:0.5, fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com