Preparation method of L-polylactide-modified MgO nano-rod composite material

A technology of L-polylactic acid and composite material, which is applied in the field of preparation of L-polylactic acid-modified MgO nanorod composite material, can solve the problems of limited wide application, rapid degradation speed and strength loss, and inability to achieve simple and easy process. effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

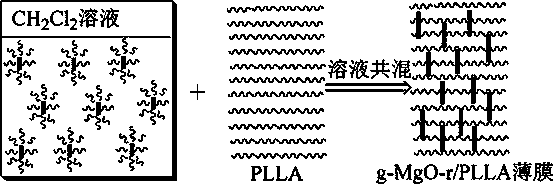

Image

Examples

Embodiment 1

[0030] A preparation method of L-polylactic acid-modified MgO nanorod composite material, comprising the steps of:

[0031] 1) Preparation of MgO nanorods

[0032] MgC1 2 ·6H 2 O was dissolved in deionized water to obtain a magnesium chloride solution with a concentration of 0.6g / ml. After stirring at 25°C for 20 minutes, add 0.45g of MgO nanorods with a diameter of less than 50nm and an aspect ratio greater than 10, and continue stirring at 45°C. 21h, then centrifuged, washed with water four times, finally washed with ethanol, centrifuged to obtain oxychloride cement [Mg x (OH) y Cl z . n h 2 O] precipitate, after above-mentioned precipitate is washed with water, ethanol successively, join concentration and be in the 4M NaOH solution, oxychloride cement [Mg x (OH) y Cl z . n h 2 O] The amount ratio of the precipitate to the NaOH solution is 75g: 100ml, stirred and reacted at 45°C for 3h, then washed with water and ethanol in turn, dried, and calcined at 600°C...

Embodiment 2

[0039] A preparation method of L-polylactic acid-modified MgO nanorod composite material, comprising the steps of:

[0040] 1) The preparation of MgO nanorods is the same as in Example 1;

[0041] 2) Surface modification of MgO nanorods

[0042] According to the mass ratio of 1:9.6:1, DL-malic acid, polylactic acid with a molecular weight of 500-1000, and MgO nanorods were mixed in a single-necked flask, and the magnetic stirring reaction was carried out at a vacuum degree of 0.05MP and a temperature of 145°C for 8.5 h, after washing the obtained product three times with ethyl acetate, vacuum drying at 45° C. for 20 min to obtain powdery modified MgO nanorods;

[0043] 3) The preparation of the composite material is the same as in Example 1, and a film-like L-LA-modified MgO nanorod composite material with a concentration of 0.5 wt% can be obtained.

[0044] After cutting the prepared film-like composite material into pieces, it is injection-molded by an injection molding ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com