Method for preparing polyimide by utilizing ionic liquid and application of polyimide prepared by method

A technology of ionic liquid and polyimide, which is applied in the application field of preparing polyimide by using ionic liquid and the prepared polyimide, can solve the problems of unenvironmental protection and few types in the preparation process, and achieve the preparation process Environmentally friendly, easy to operate, few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

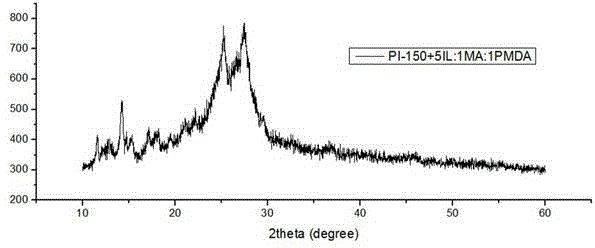

[0040] Add 1.26g (0.01mol) of melamine into a 50mL round bottom flask, then add 11.30g of 1-butyl-3-methyl-imidazolium tetrafluoroborate (0.05mol), stir and mix the two, and heat to a constant temperature of 80°C 30 minutes. After the melamine is completely evenly distributed, add 2.18g (0.01mol) white powder of pyromellitic anhydride to the reaction flask, heat to 150°C, react at constant temperature for 8 hours, and cool to room temperature to obtain a light yellow thick substance. The system was washed with distilled water and ethanol respectively, filtered and dried with suction to obtain a polyimide photocatalytic material. The XRD patterns of polyimide photocatalytic materials are as follows: figure 1 shown. In the XRD pattern of PI, there appeared several new peaks that did not exist in the monomer, such as the peak at 2θ=14.26° and the strong peak at 2θ=27.48°. Among them, the strong peak at 2θ=27.48° corresponds to the interlayer spacing of 0.324nm between two-dime...

Embodiment 2

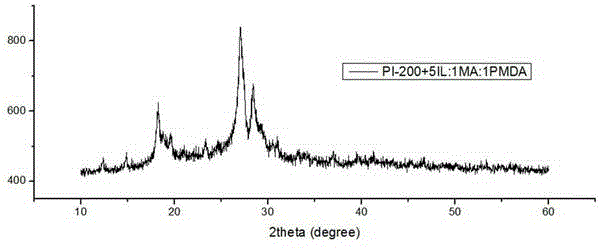

[0042]Add 1.26g (0.01mol) of melamine into a 50mL round bottom flask, then add 11.30g of 1-butyl-3-methyl-imidazolium tetrafluoroborate (0.05mol), stir and mix the two, and heat to a constant temperature of 80°C 30 minutes. After the melamine is completely evenly distributed, add 2.18g (0.01mol) white powder of pyromellitic anhydride to the reaction flask, heat to 200°C, react at constant temperature for 8 hours, and cool to room temperature to obtain a light yellow thick substance. The system was washed with distilled water and ethanol respectively, filtered and dried with suction to obtain a polyimide photocatalytic material. The XRD patterns of polyimide photocatalytic materials are as follows: figure 2 shown. The XRD patterns of PI showed strong peaks at 2θ=18.26° and 2θ=27.08°. Among them, the strong peak at 2θ=27.48° corresponds to the interlayer spacing between two-dimensional structures of 0.329nm, which is closer to the graphene interlayer spacing of 0.330nm, indi...

Embodiment 3

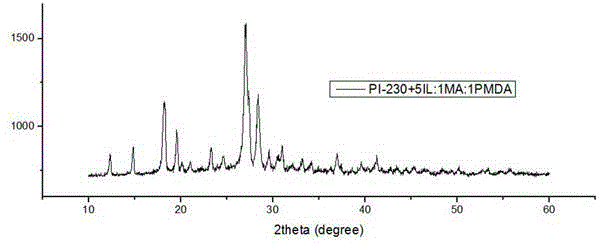

[0044] Add 1.26g (0.01mol) of melamine into a 50mL round bottom flask, then add 11.30g of 1-butyl-3-methyl-imidazolium tetrafluoroborate (0.05mol), stir and mix the two, and heat to a constant temperature of 80°C 30 minutes. After the melamine is completely evenly distributed, add 2.18g (0.01mol) white powder of pyromellitic anhydride to the reaction flask, heat to 230°C, react at constant temperature for 8 hours, and cool to room temperature to obtain a light yellow thick substance. The system was washed with distilled water and ethanol respectively, filtered and dried with suction to obtain a polyimide photocatalytic material. The XRD patterns of polyimide photocatalytic materials are as follows: image 3 As shown, the SEM and TEM of polyimide photocatalytic materials are as Figure 4 and Figure 5 As shown, it can be seen from the microstructure that the material has a branched structure after polymerization and a hole structure that is conducive to catalysis.

[0045] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com