Ship torque gyro stabilizer and stabilizing method

A technology of moment gyroscope and anti-rolling device, which is applied in the direction of directly using the gyroscope to reduce the motion of the ship, can solve the problems of high cost and complex structure of anti-rolling fins, achieve simple structure, improve seaworthiness and comfort, and promote application promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

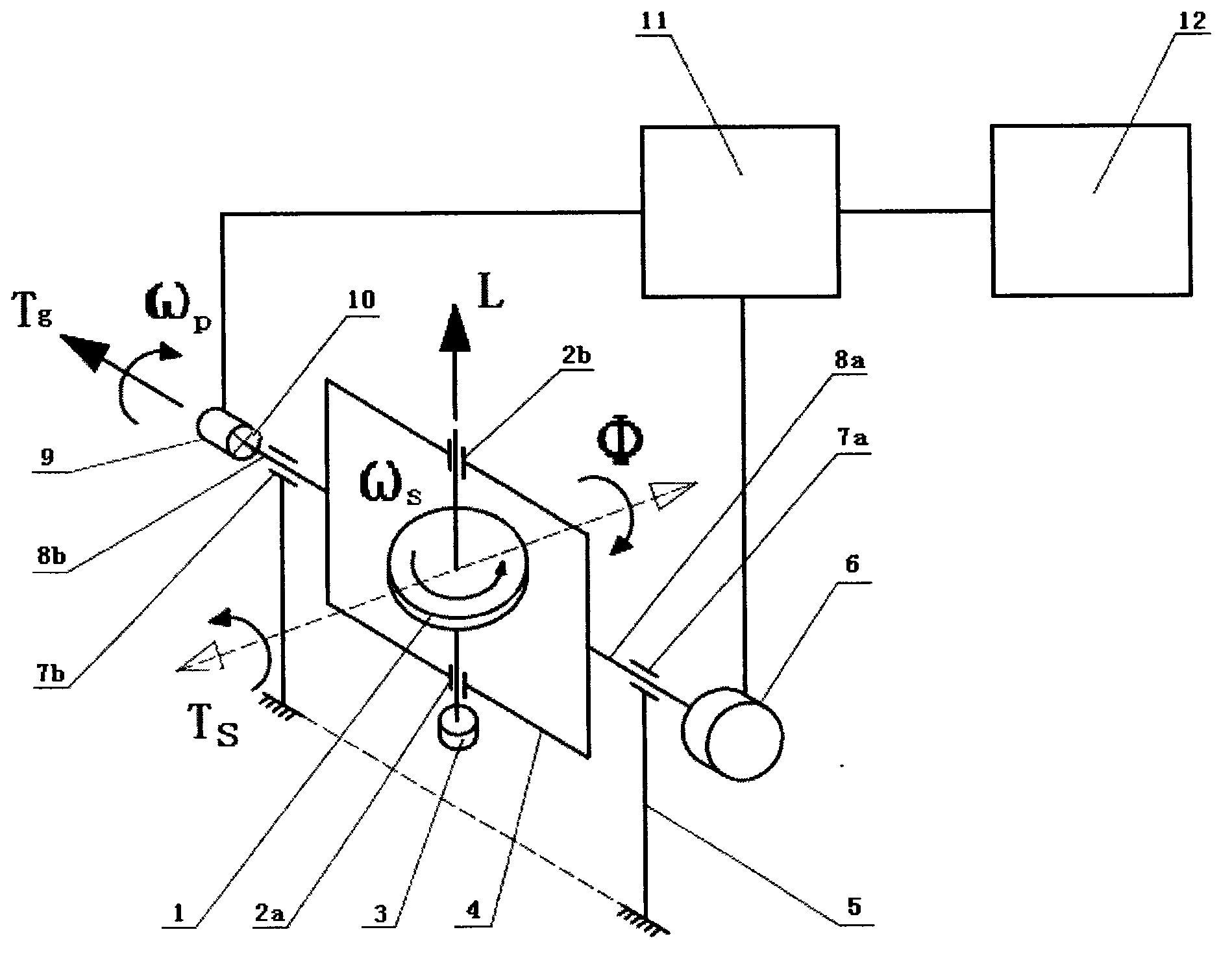

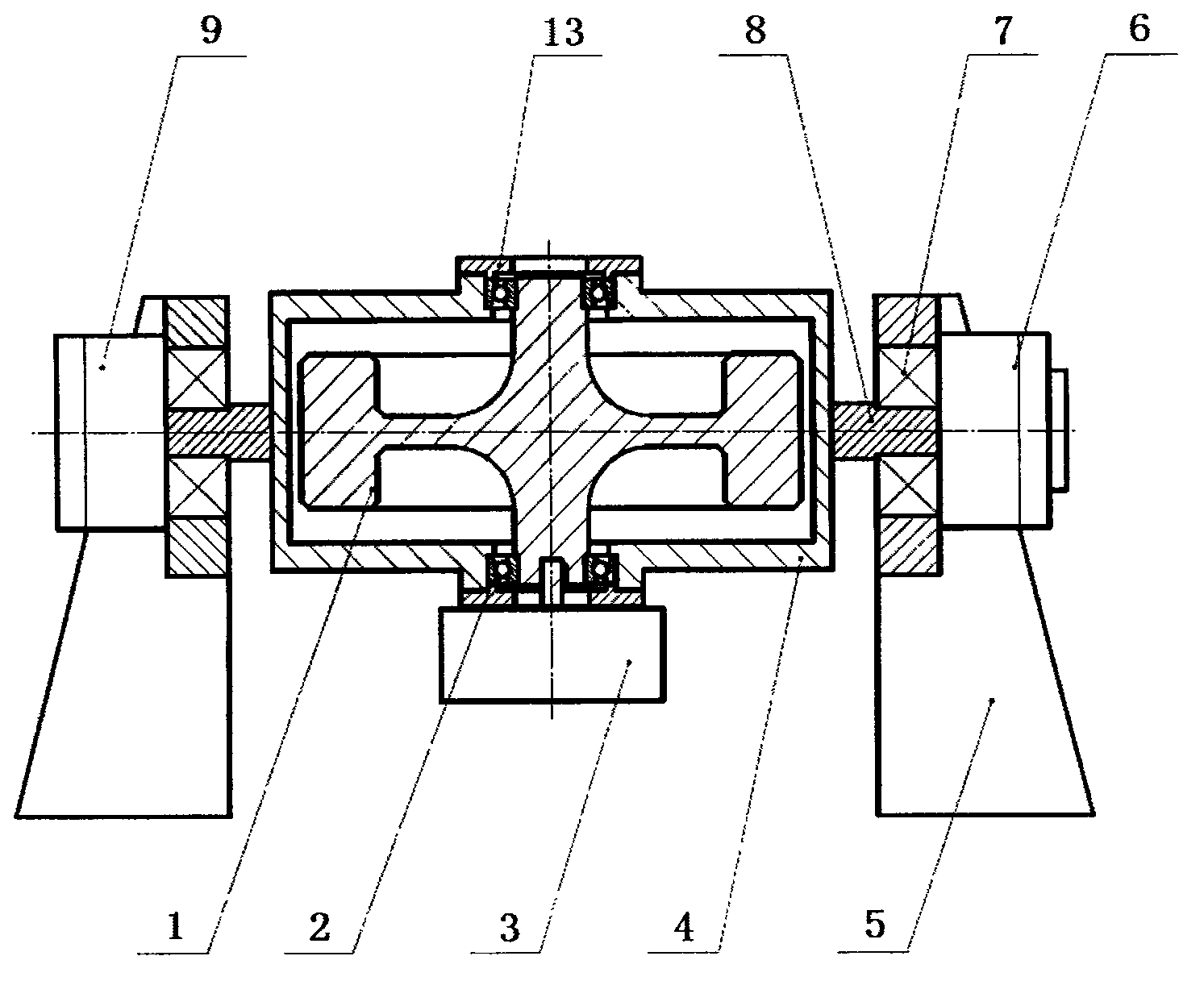

[0018] Such as figure 1 and figure 2 As shown, the moment gyro stabilization device of the present invention is composed as follows. The gyro rotor 1 is fixed on the inner frame 4 through the bearings 2a, 2b, driven by the flat motor 3, and the flat motor 3 is also fixed on the inner frame 4. The inner frame 3 is fixed on the base 5 through trunnions 8a, 8b and bearings 7a, 7b on both sides, and can rotate (precess) around the trunnions. Damper (magnetic powder brake) 6, servo motor 9 and sensor 10 are respectively installed on both sides of the trunnion, and controller 11 receives the signal of sensor 10 through the line and controls the action of damper (magnetic powder brake) 6 and servo motor 9. The battery 12 supplies power to the device. Base 5 can be fixed on any position where the strength of the hull is sufficient.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com