Technology for producing high-frequency microwave copper-clad plate with dielectric constant of 3.4

A high-frequency microwave and dielectric constant technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problem of poor adhesion between metal copper and hole walls, complex metallization process, and in-hole lines Disconnection and other problems, to achieve the effect of good mechanical performance, low cost, and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

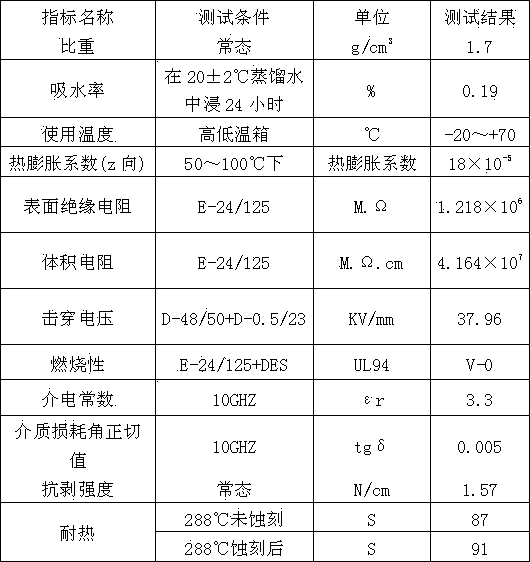

Image

Examples

Embodiment Construction

[0021] 1. Polyphenylene ether resin glue solution modification:

[0022] Raw materials and ratio

[0023] Material Proportion amount (g) toluene 315-330 Allyl Bisphenol A 1.40-1.50 Polyphenylene ether 90.0-105.0 Benzoyl peroxide 2.20-2.35 triallyl cyanate 17.00-17.45 dicumyl peroxide 48.0-51.5 Decabromodiphenylethane 14.5-16.0 Antimony trioxide 5.5-6.2

[0024] First dissolve polyphenylene ether and benzoyl peroxide with toluene, after mixing, add allyl bisphenol A; keep the solution warm for reaction; then add dicumyl peroxide and triallyl cyanate to continue the reaction; After the reaction is completed, the resin glue is cooled immediately; finally, the composite flame retardant decabromodiphenylethane and antimony trioxide are added, and the resin glue is evenly stirred to obtain the resin glue;

[0025] Resin glue control index: gelation time: 125±15 seconds

[0026] Viscosity: 21±4 seconds,

[0027] Solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com